Rolling force and rolling moment setting method for steel strip cold rolling full deformation area

A technology of rolling torque and setting method, applied in the field of rolling production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

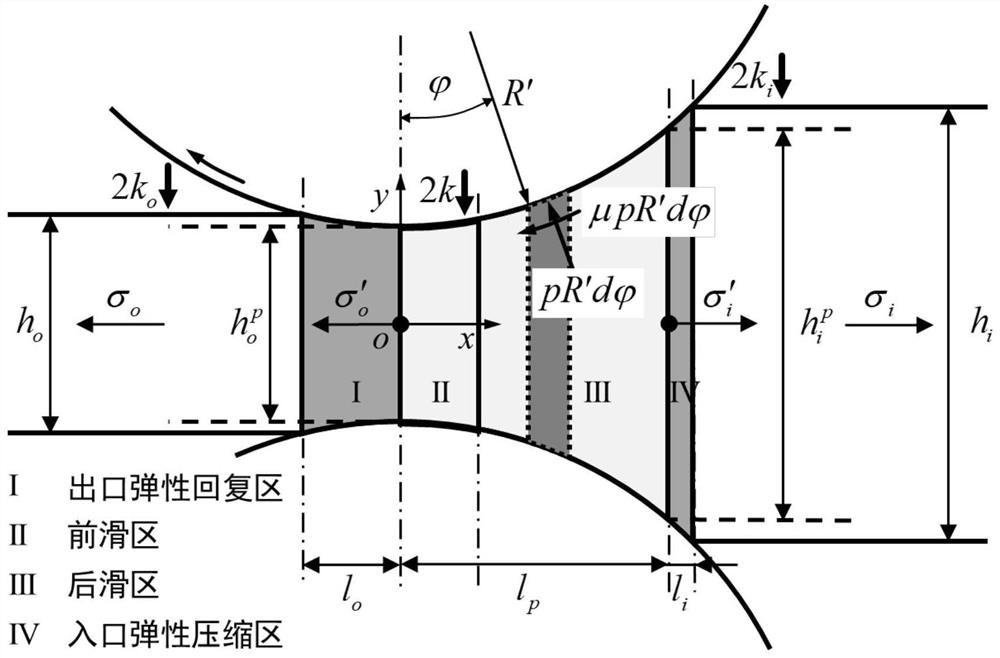

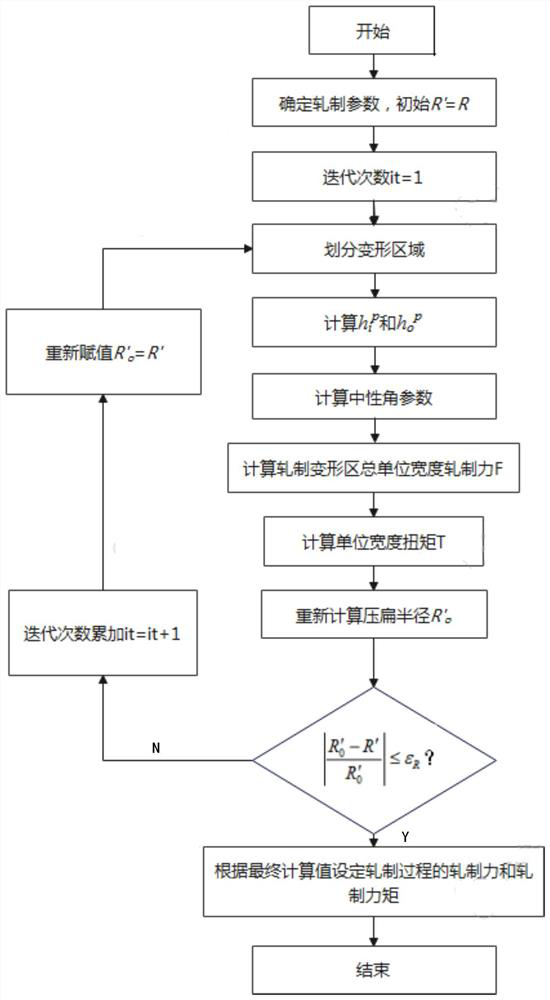

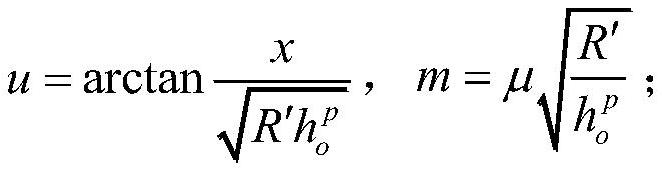

Method used

Image

Examples

Embodiment 1

[0177] Taking the 1740mm five-stand six-high tandem cold rolling mill as an example, the work roll diameter of the mill is 430-480mm, the intermediate roll diameter is 510-580mm, the backup roll diameter is 1315-1465mm, and the maximum rolling force of the mill is 32000kN. The thickness of each rolling pass of DP590 steel strip with a width of 1358mm before rolling (ie, the thickness at the entrance of the rolled steel strip / thickness before rolling), the thickness after rolling (the thickness at the exit of the rolled steel strip / the thickness after rolling), the front and rear tension and the use of the present invention The rolling force calculated by the method and the measured rolling force are shown in Table 1.

[0178] Table 1 Example 1 Steel strip thickness, front and rear tension, calculated rolling force and measured rolling force

[0179]

[0180]

[0181] It can be seen from Table 1 that the error between the cold rolling force of DP590 steel strip calculated...

Embodiment 2

[0183] Taking the 1740mm five-stand six-high tandem cold rolling mill as an example, the work roll diameter of the mill is 430-480mm, the intermediate roll diameter is 510-580mm, the backup roll diameter is 1315-1465mm, and the maximum rolling force of the mill is 32000kN. The thickness of each rolling pass of W780QX steel strip with a width of 1223 mm before rolling (namely, the thickness at the entrance of the rolled steel strip / thickness before rolling), the thickness after rolling (the thickness at the exit of the rolled steel strip / the thickness after rolling), the front and back tension and the use of the present invention The rolling force calculated by the method and the measured rolling force are shown in Table 2.

[0184] Table 2 Example 2 Steel strip thickness, front and rear tension, calculated rolling force and measured rolling force

[0185]

[0186] It can be seen from Table 2 that the error between the cold rolling force and the measured rolling force of the...

Embodiment 3

[0188] Taking a 1340mm six-high tandem cold rolling mill as an example, the work roll diameter of the mill is 420-460mm, the intermediate roll diameter is 440-490mm, the backup roll diameter is 1000-1090mm, and the maximum rolling force of the mill is 15000kN. The thickness of each rolling pass of 16Mn steel strip with a width of 919.0mm (thickness at the entrance of the rolled steel strip / thickness before rolling), thickness after rolling (ie the thickness at the exit of the rolled steel strip / thickness after rolling), front and rear tension and use The rolling force calculated by the inventive method and the measured rolling force are shown in Table 3.

[0189] Table 3 Example 3 Steel strip thickness, front and rear tension, calculated rolling force and measured rolling force

[0190]

[0191] As can be seen from Table 3, the 16Mn steel strip cold rolling force calculated by the present invention has an error of less than 7.4% and the measured rolling force, and the error...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com