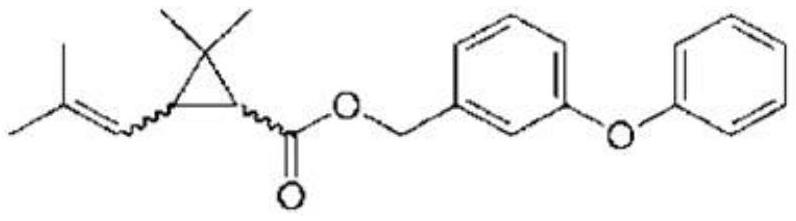

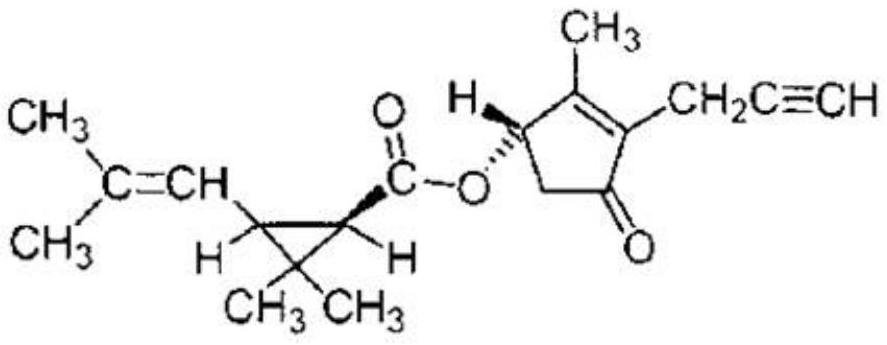

Mixture of encapsulated phenethofenprox and emulsified d-prallethrin

A technology of dextramethrin and phenothrin, applied in the field of new water-based preparations, which can solve the problems of decreased effectiveness and insufficient residual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0078] Production of Capsule Suspension (CS)

[0079] For 5 kg of final product, 1670 g of capsule suspension (CS) are required. All data are expressed in weight percent.

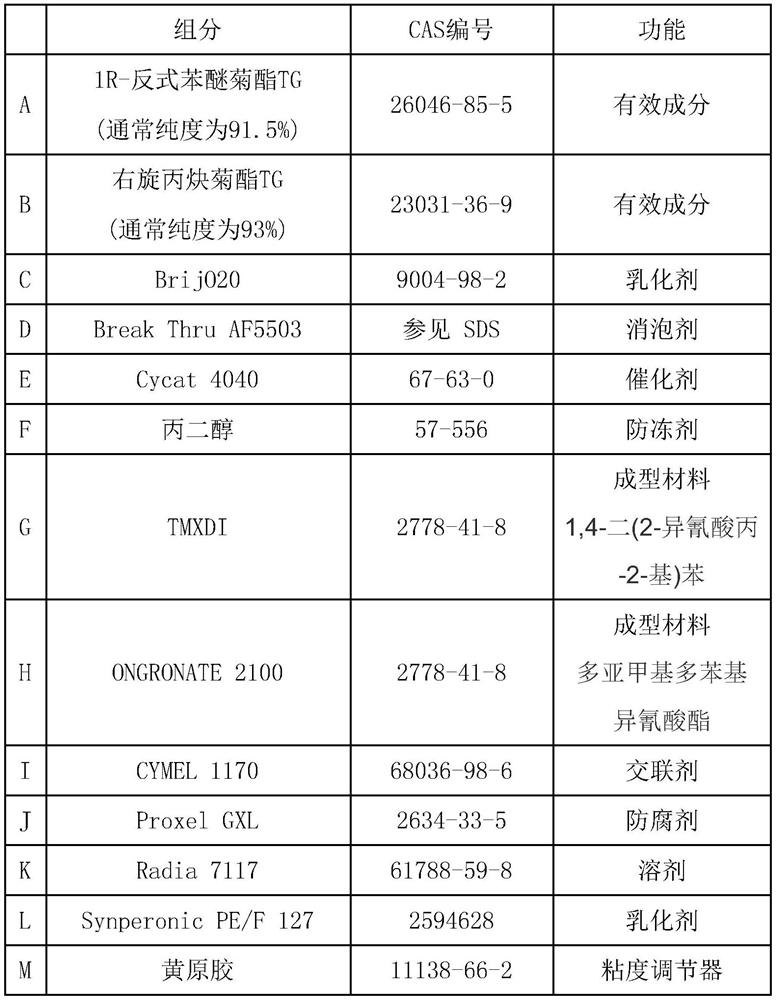

[0080] Table 4

[0081]

[0082] Prior to the emulsification process, the water and oil phases were placed in a 2-liter jacketed reactor at 40°C.

[0083] In a 2-liter jacketed reactor equipped with a clawless mixer and a high shear mixer, the aqueous phase was added at 40°C. When the clawless mixer was turned on at 1600 rpm, the oil phase was added very quickly (~1 minute) to the water phase, thereby starting the emulsification polymerization process.

[0084] After complete emulsification of the entire oil phase, the high shear mixer was turned on at 4600 rpm. The emulsion polymerization ended after 4 minutes.

[0085] The capsule suspension was then transferred at 60°C to another jacketed reactor equipped only with an anchor stirrer at 36 rpm.

[0086] The capsule suspension was stirred for 3 ho...

example 2

[0099] Production of Capsule Suspension (CS)

[0100] For a 5kg final product, 1670g CS is required. All data are expressed in weight percent.

[0101] Table 6

[0102] oil phase weight percentage water box weight percentage 1R-trans-phenothrin 31.932 Synperonic PE / F 127 2.25 TMXDI 0.450 BrijO20 0.056 ONGRONAT 2100 3.150 Zephrym PD3315 3.00 Cymel 1170 0.300 water 44.912 Radia 7117 13.500 Cycat 4040 0.45

[0103] The production method is the same as in Example 1.

[0104] Production of Emulsion in Water (EW)

[0105] For a 5kg final product, 3330g emulsion in water (EW) is required. All data are expressed in weight percent.

[0106] Table 7

[0107]

[0108]

[0109] The production of the aqueous emulsion and the production of the final suspension was carried out as in Example 1.

example 3

[0111] Production of Capsule Suspension (CS)

[0112] For 5 kg of final product, 1670 g of capsule suspension (CS) are required. All data are expressed in weight percent.

[0113] Table 8

[0114] oil phase weight percentage water box weight percentage 1R-trans-phenothrin 31.932 Synperonic PE / F 127 2.52 TMXDI 0.900 BrijO20 0.056 ONGRONAT 2100 4.200 Zephrym PD3315 3.0 Cymel 1170 0.75 water 41.102 Radia 7117 15.00 Cycat 4040 0.54

[0115] The production method is the same as in Example 1.

[0116] Production of Emulsion in Water (EW)

[0117] For a 5kg final product, 3330g emulsion in water (EW) is required. All data are expressed in weight percent.

[0118] Table 9

[0119] Propylene Glycol 11.25 Zephrym PD3315 3.00 Xanthan Gum 0.525 Break Thru AF5503 0.0225 Proxel GXL 0.15 water 83.442 Prallethrin TG 1.61

[0120] The production of the aqueous emulsion and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com