Eye shaping designer with accurate measurement

A technology of eye plastic surgery and designer, applied in the direction of eye testing equipment, diagnostic recording/measurement, sensors, etc., can solve the problems of distance deviation, effect effect, inconvenient design tools, etc., to achieve precise control, avoid distance deviation, prevent The effect of distance bias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

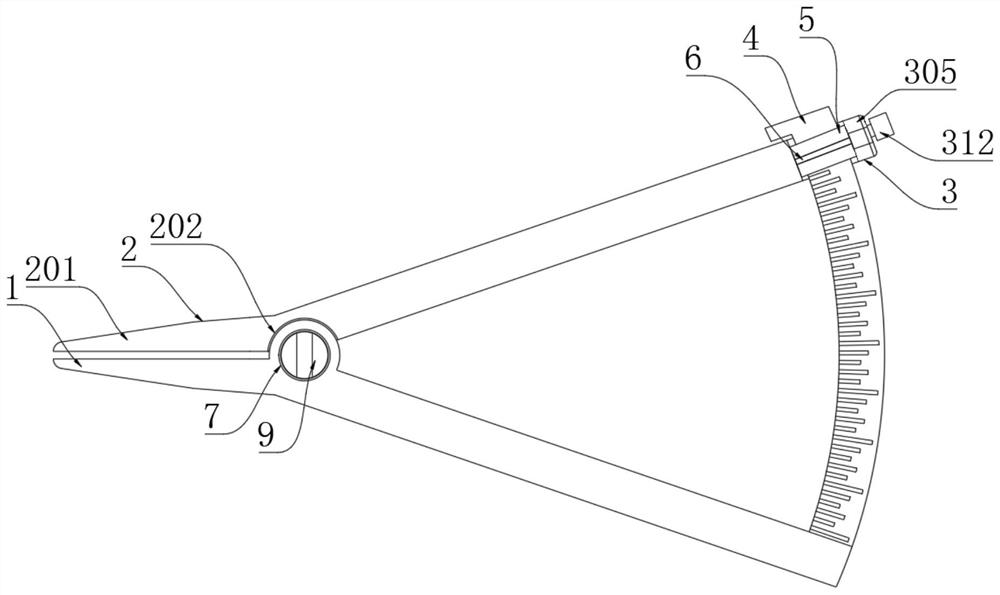

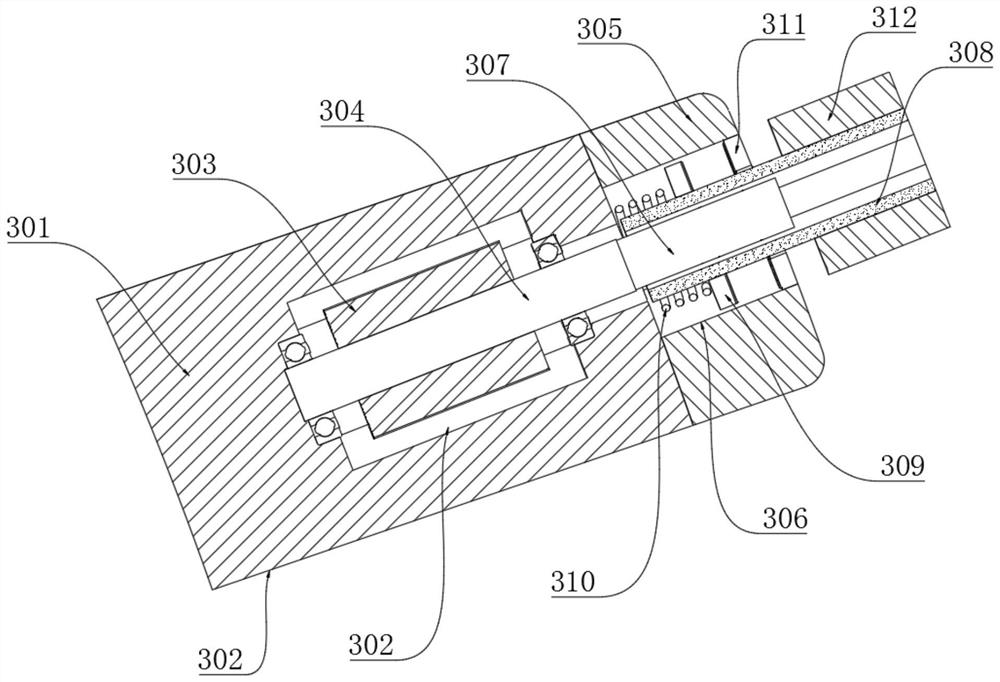

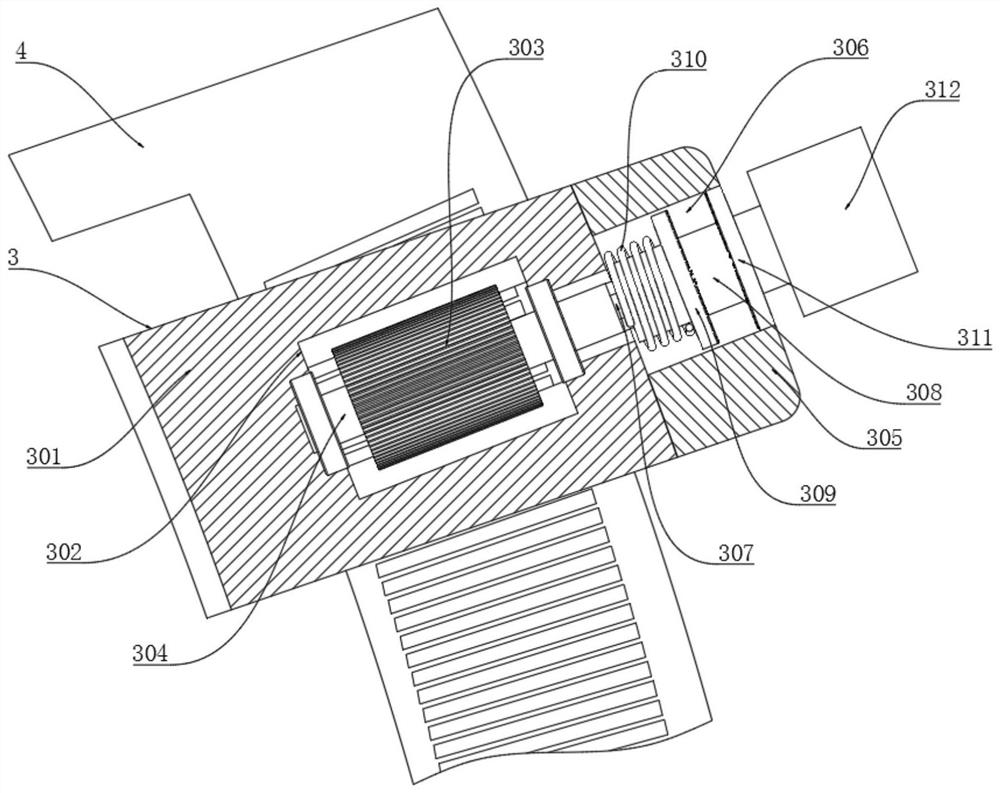

[0041] see Figure 1-4 and 6, the present invention provides a technical solution: including a rotating arm 1, a design measuring assembly 2 and a stable driving assembly 3, the design measuring assembly 2 is rotatably arranged in the middle of the rotating arm 1 and is used to cooperate with the rotating arm 1 and be on the dial The measured length is shown on 4, and the rotating arm 1 and the design measuring assembly 2 are rotated relative to each other, and the part of the tip of the rotating arm 1 and the design measuring assembly 2 is used as a reference for measurement, wherein the design measuring assembly 2 includes a rotating setting with the rotating arm 1. The first measuring arm 201, the first fixing block 301 is welded on one end of the first measuring arm 201 corresponding to the position of the dial 4, and one end of the first measuring arm 201 corresponding to the position of the positioning column 9 is provided with a first groove 202, The inner wall of a gro...

Embodiment 2

[0047] see Figure 5-7 The difference from the first embodiment is that a concave ring is opened in the middle of the positioning column 9, and the inner wall of the concave ring is movably connected with a torsion spring 204. The first measuring arm 201 and the rotating arm 1 correspond to the tops of the two ends of the torsion spring 204 Both are provided with mounting holes 205 respectively, and the two ends of the torsion spring 204 are movably plugged into the inner walls of the two mounting holes 205, so that the device can quickly operate when the first blocking disk 309 and the second blocking disk 311 are in a separated state. Return to the initial state, so that the embodiment has the function of elastic reset.

Embodiment 3

[0049] see Figure 8-13, and the difference from the first embodiment is that the design measurement assembly 2 includes two rotating arms, that is, the design measurement assembly 2 includes a second measurement arm 206 and a third measurement arm 207 that are rotatably arranged with the rotating arm 1. The second measurement The arm 206 and the third measuring arm 207 are arranged to rotate relative to each other, the first fixing block 301 is welded to one end of the third measuring arm 207 corresponding to the position of the dial 4 , and the second measuring arm 206 and the third measuring arm 207 are corresponding to the position of the positioning column 9 One end is respectively provided with a second groove 208, the inner wall of the second groove 208 is welded with a second mounting ring 209, the second mounting ring 209 is movably connected to the inner wall of the mounting groove 8, and the positioning column 9 is rotatably connected to the second mounting ring 209....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com