Multifunctional ultrasonic cleaning machine

An ultrasonic and multi-functional technology, applied in the field of ultrasonic cleaning, can solve the problems of single function and inability to air-dry stainless steel pipes, etc., and achieve the effects of reducing labor intensity, increasing convenience, and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

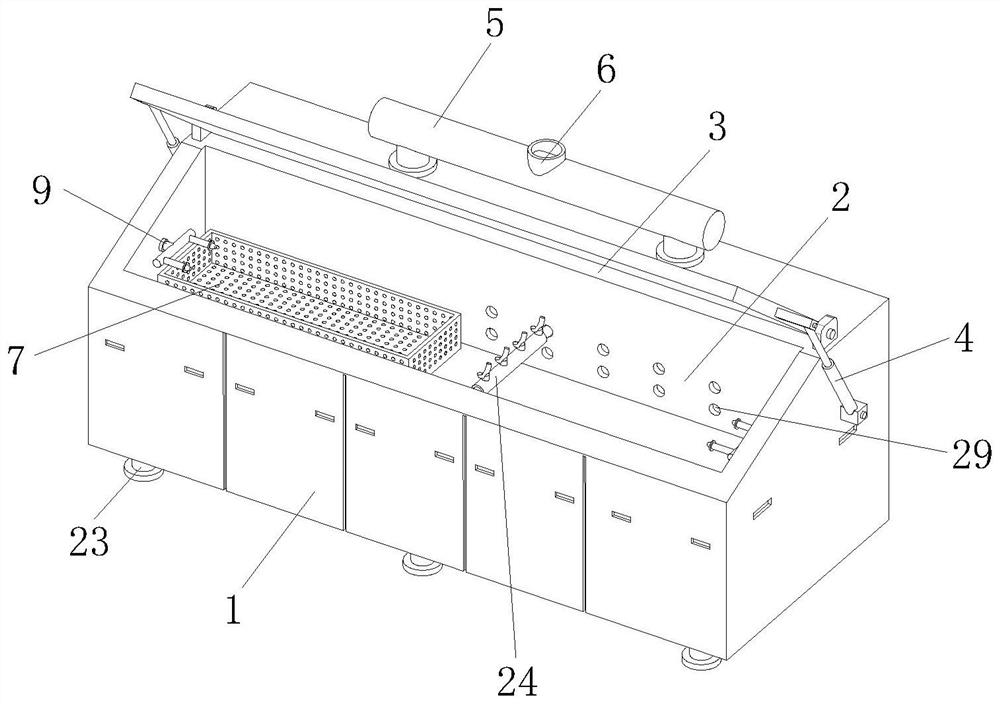

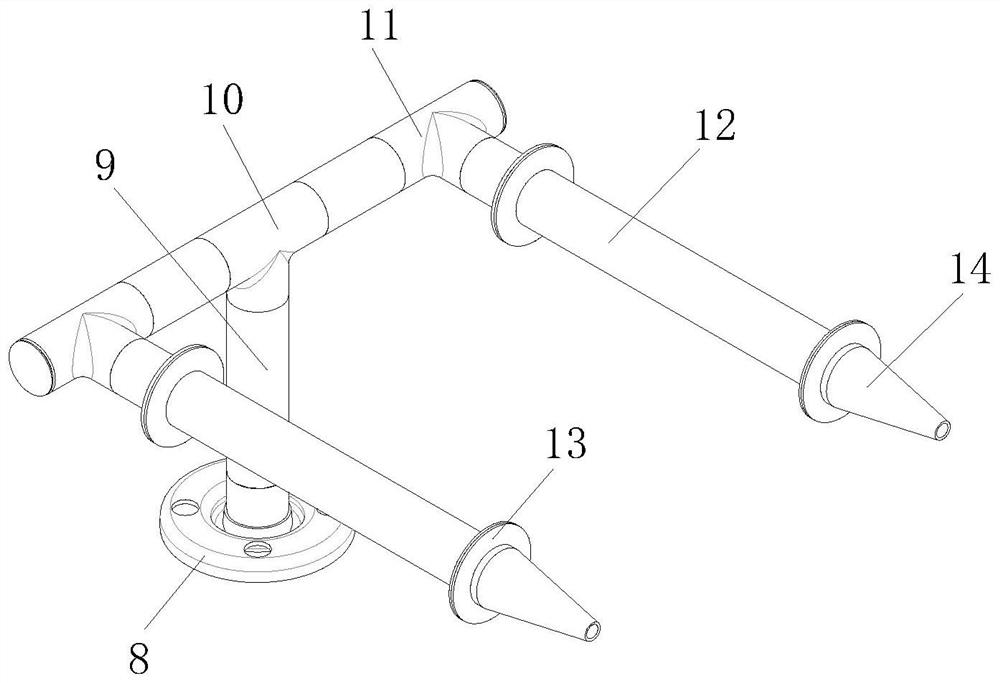

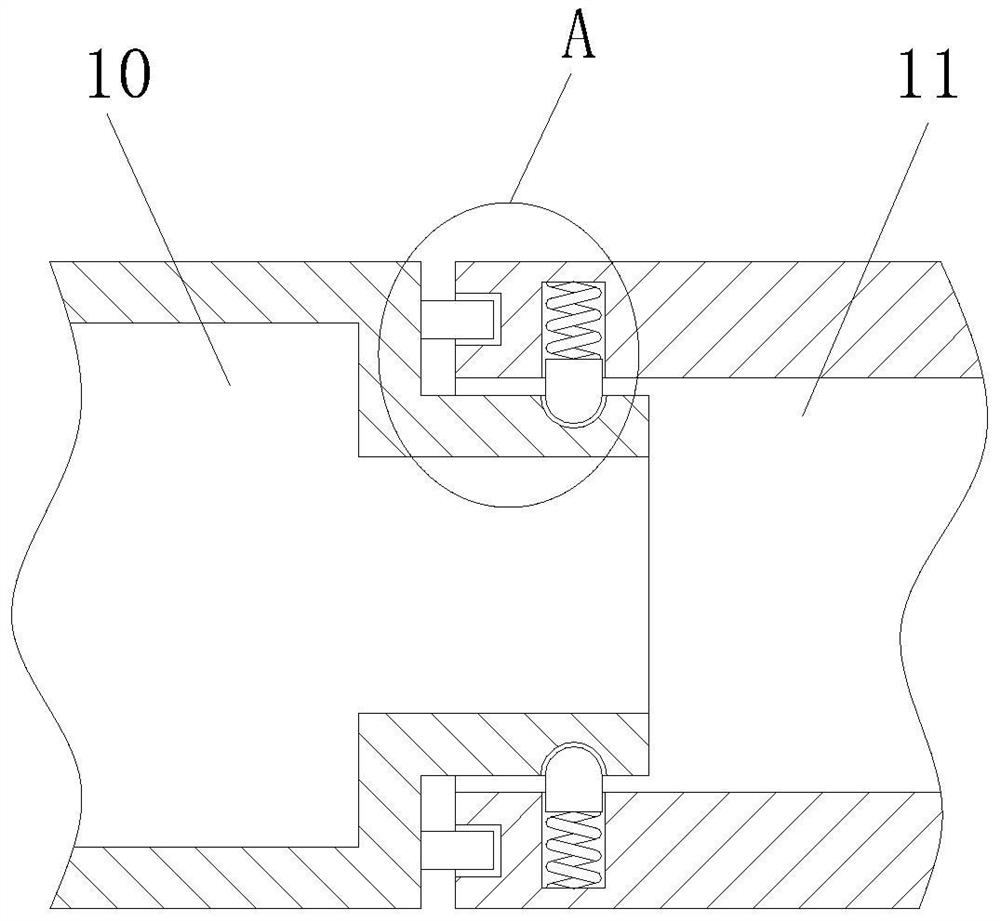

[0028] see Figure 1-6 , a multifunctional ultrasonic cleaning machine, comprising a casing 1, a cleaning tank 2 is provided on the top surface of the casing 1, a cover plate 3 matching the cleaning tank 2 is movably connected on the top surface of the casing 1, and the left and right side walls of the cover plate 3 A pneumatic strut 4 is movably connected respectively, and the other end of the pneumatic strut 4 is movably connected with the side wall of the casing 1. A pipe 5 is fixedly connected to the top surface of the casing 1 near the rear side, and the pipe 5 is communicated with the cleaning tank 2. 5. An exhaust pipe 6 is fixedly connected to the side wall, and a screen 7 is movably connected to the inner cavity of the cleaning tank 2. The left and right side walls of the cleaning tank 2 are respectively provided with a flushing mechanism. The bottom ends of the legs 23 are fixedly connected with anti-skid pads, and the inner cavity of the cleaning tank 2 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com