A combined regeneration method for producing high-grade lubricating oil products from waste lubricating oil

A waste lubricating oil and lubricating oil technology, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrogenation process, etc., can solve the problems of low product performance, high cost, complicated waste lubricating oil treatment methods, etc., and achieve good product properties , high added value, and more insolubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

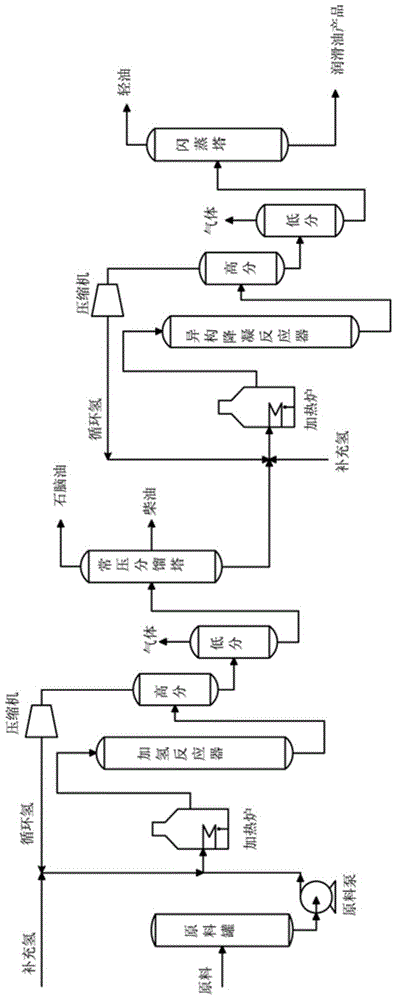

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the used Pt-Pd catalyst of the present invention:

[0030] Using ZSM-5 molecular sieve as the carrier, take an appropriate amount of solution containing Pt and Pd, impregnate the carrier by equal volume impregnation method, place it at room temperature for 12 hours after impregnation, then dry it at 110°C for 6 hours, and roast it at 500°C for 6 hours to finally get Pt-Pd / Al 2 o 3 The catalyst, wherein the mass fraction of Pt and Pd on the catalyst can be adjusted by the amount of metal in the solution containing Pt and Pd.

[0031]The details are as follows: impregnate 100g of ZSM-5 molecular sieve with 50ml of Pt 0.3g / 100ml and Pd 0.8g / 100ml aqueous solution, place it at room temperature for 12h after impregnation, then dry at 110°C for 6h, and roast at 500°C for 6h to finally get the Pt-Pd catalyst , wherein the loading of Pt is 0.15w%, and the loading of Pd is 0.4w% of the catalyst. γ-Al 2 o 3 Specific surface area ≥ 180m 2 / g, the p...

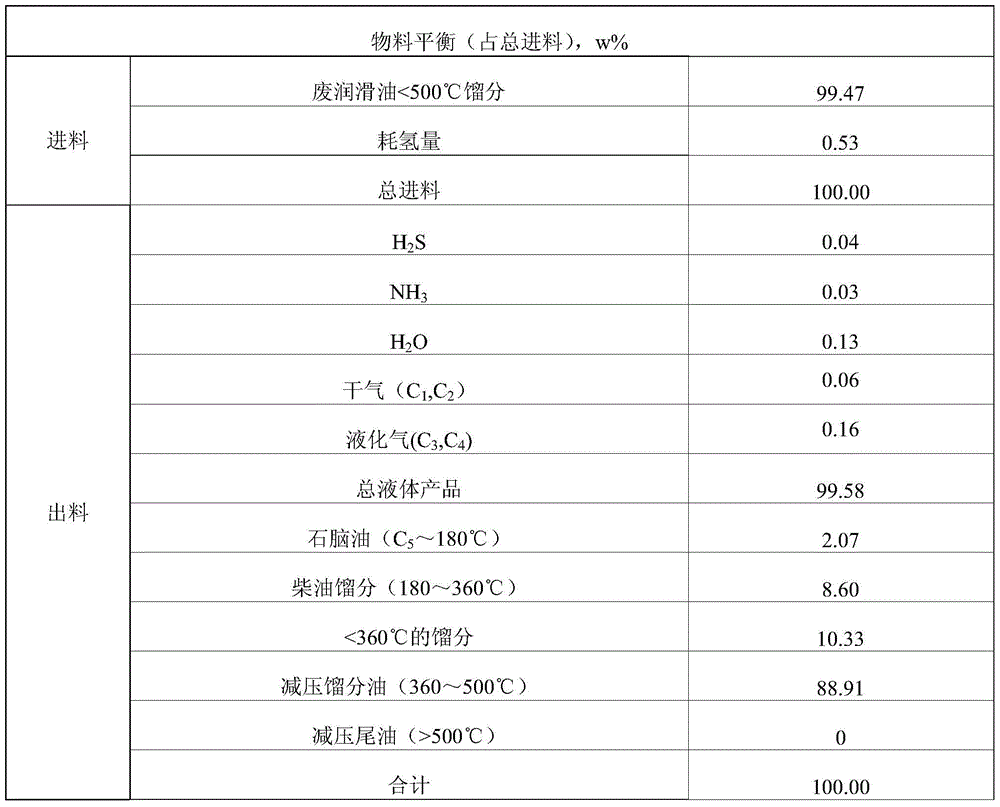

Embodiment 1

[0038] According to the above process, combined with specific waste lubricating oil, the reaction is carried out, and the specific conditions are as follows: hydrofining reaction temperature 340°C, reaction pressure 18.0MPa, hydrogen-oil ratio 1000:1, fresh raw material space velocity 1.0h -1 , the first catalyst is Mo-W / γ-Al 2 o 3 , NiO in the catalyst is 3.6w%, MoO 3 is 23.2w%, and the amount of catalyst added is 500 μg of the first catalyst / g<500°C fraction;

[0039] Isomerization decondensation reaction: temperature 300°C, reaction pressure 12MPa, hydrogen-oil ratio 800:1, feed space velocity 2.0h -1 , the loading of Pt in the second catalyst is 0.15w%, the loading of Pd is 0.4w% of the catalyst, and the addition amount is 50 μg of the second catalyst / g<500 ° C fraction, the specific data are as follows:

[0040] (1) Raw material properties of waste lubricating oil (accounting for total feed)

[0041] project

[0042] Ni

[0043] Total tetr...

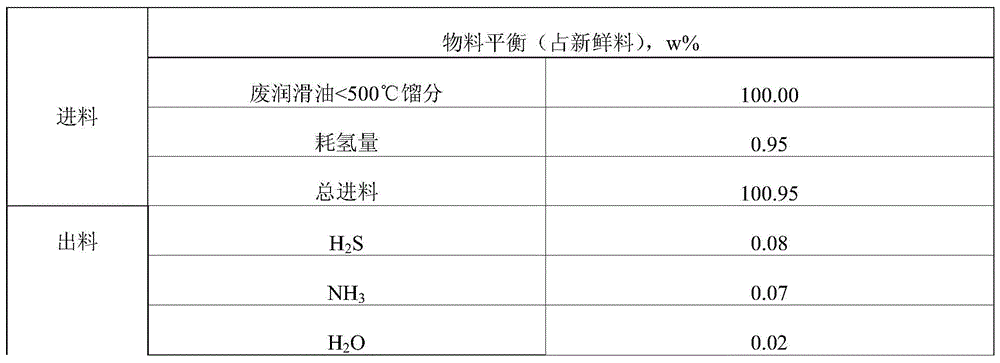

Embodiment 2

[0052] According to the above process, combined with specific waste lubricating oil, the reaction is carried out. The specific conditions are as follows: hydrofining reaction temperature 360 ° C, reaction pressure 15.0 MPa, hydrogen-oil ratio 600:1, fresh raw material space velocity 0.5h -1 , the first catalyst is Mo-W / γ-Al 2 o 3 , WO in the catalyst 3 26.8w%, MoO 3 is 24.2w%, and the amount of catalyst added is 1000 μg of the first catalyst / g<500°C fraction;

[0053] Isomerization decondensation reaction: temperature 340°C, reaction pressure 8MPa, hydrogen-oil ratio 1000:1, feed space velocity 0.8h -1 , the loading of Pt in the second catalyst is 0.4w%, the loading of Pd is 0.3w% of the catalyst, and the addition amount is 100 μg of the second catalyst / g<500 ° C fraction, the specific data are as follows:

[0054] Table 1 Raw material properties of waste lubricating oil <500℃ distillate

[0055] project

[0056] Charcoal residue, w%

[0057] Materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com