Construction method of LNG high-pressure pump

A construction method and high-pressure pump technology, applied in the field of LNG pumps, can solve the problems affecting the reliability of pump body and pipeline connection, difficult to ensure the stability of LNG pumps, and occupying a large space on the ground, so as to achieve a stable enclosure support structure and improve The effect of placing stability and reducing the space occupied on the ground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

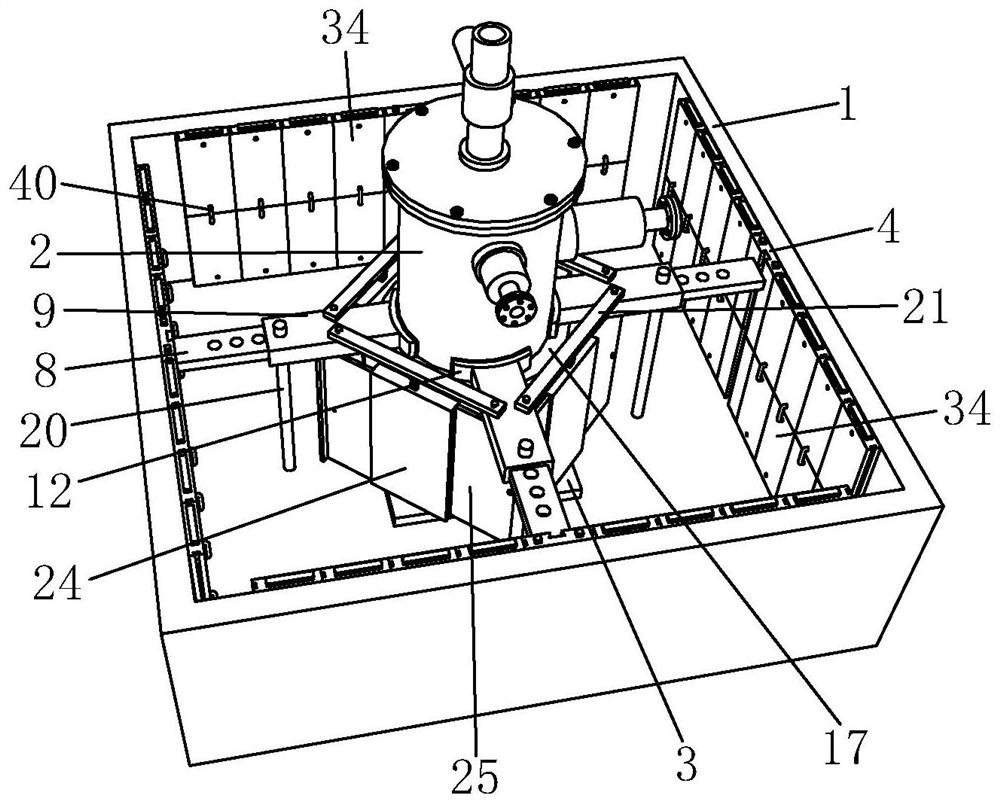

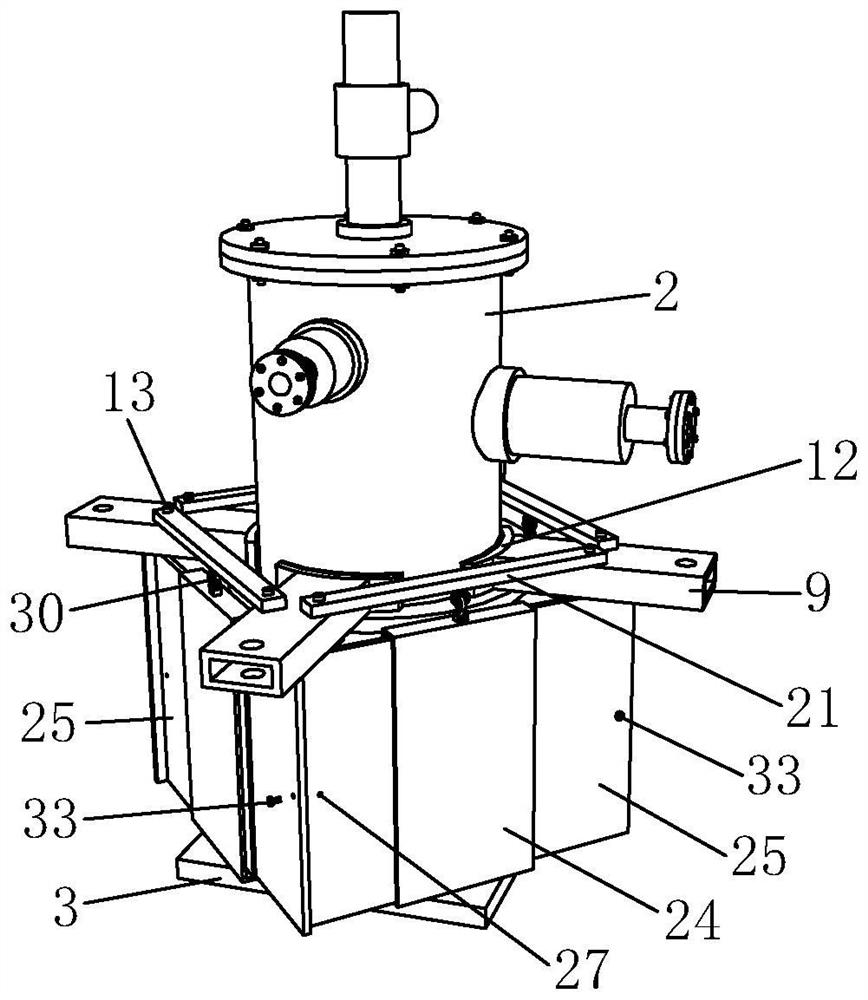

[0045] like Figure 1 to Figure 6 As shown, it is a construction method of a LNG high-pressure pump of the present invention, comprising the following steps:

[0046] (a) Excavation and cleaning of the foundation pit: Excavate the foundation pit 1 according to the construction design drawing, clean up the garbage and stones in the foundation pit 1, and level and compact the inner bottom surface of the foundation pit 1.

[0047](b) Foundation in place:

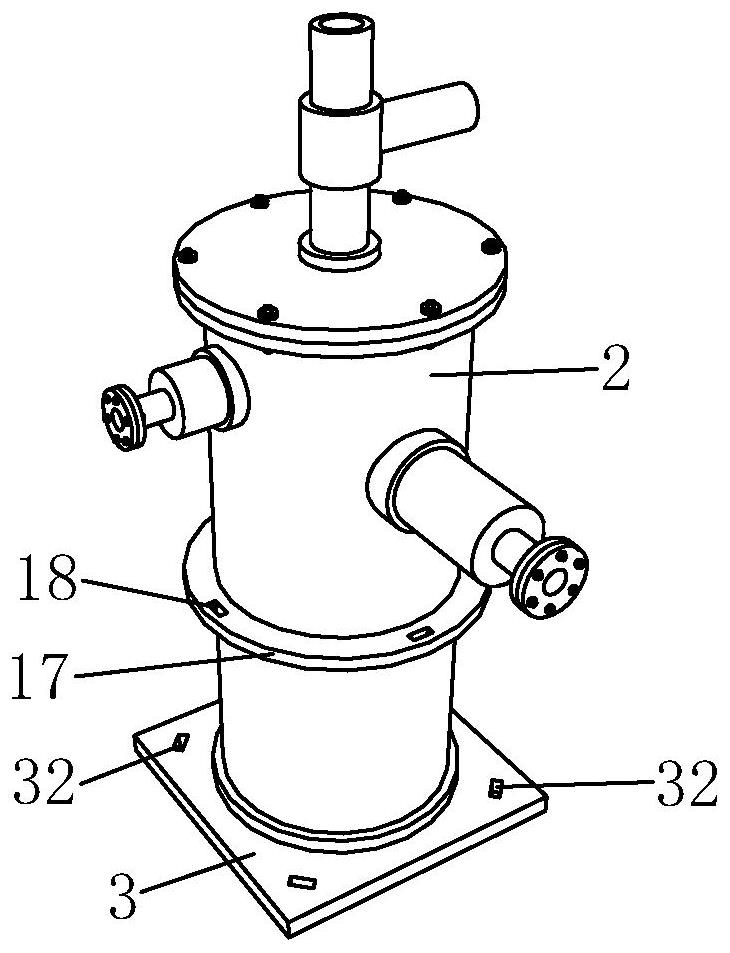

[0048] ① Mark the center point of the vertical pump on the inner bottom surface of the foundation pit 1. The specific method for the center point of the vertical pump: draw the center line of the long side and the center line of the short side of the foundation pit 1 on the inner bottom surface of the foundation pit 1. Two The intersection point of the line is the center point of the vertical pump, the fixed point is simple, the operation difficulty is low, and the construction quality is guaranteed. The center of the base 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com