Vacuum mixer

A vacuum mixer and mixer technology, applied in kitchen utensils, home utensils, applications, etc., can solve the problems of inconvenient use, inability to reverse the inner cylinder smoothly, etc., and achieve the goal of increasing torque, maximizing dehydration effect, and increasing rotation speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings. It should be noted that when reference numerals are added to components in each drawing, the same components are given the same reference numerals as much as possible, even if indicated on different drawings. Also, in describing the present invention in detail, if a detailed description of a related known structure or function is considered to deviate from the gist of the present invention, the detailed description thereof will be omitted.

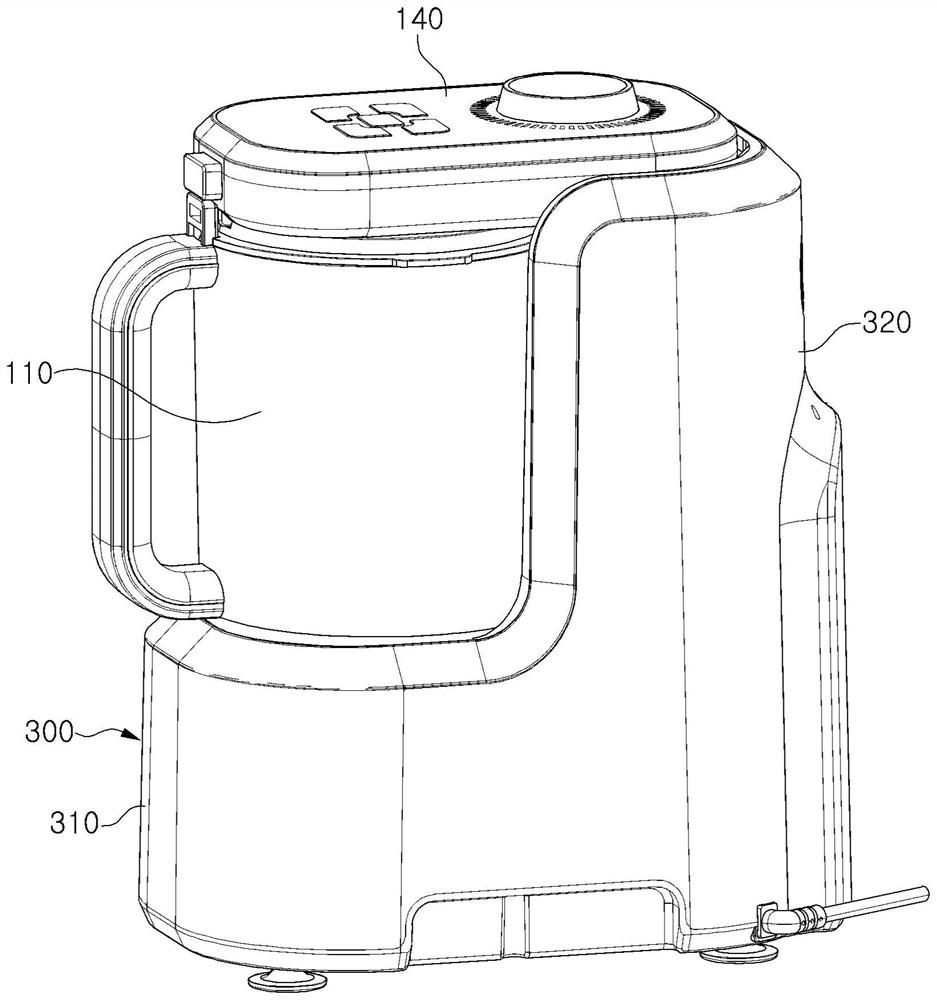

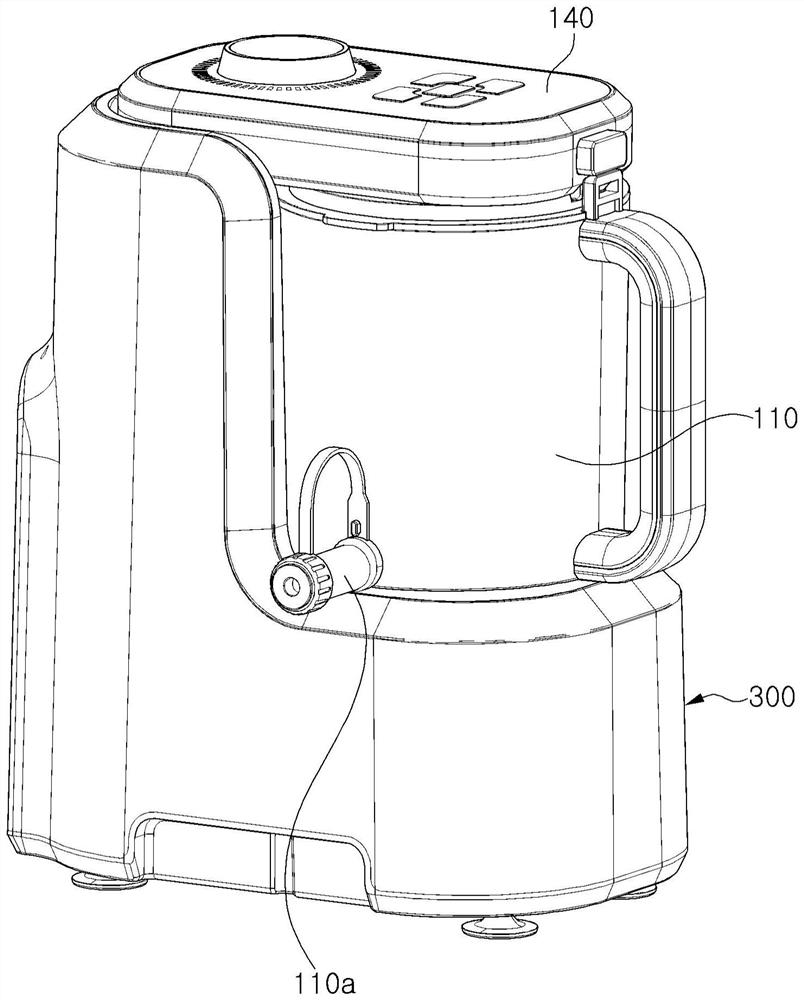

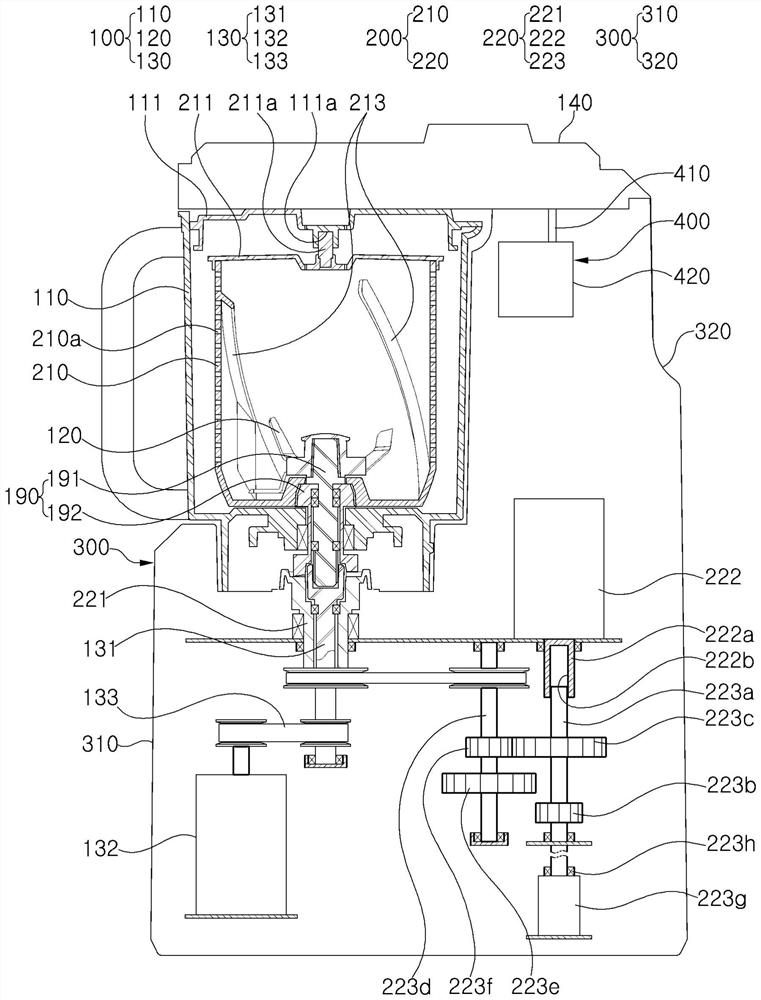

[0035] figure 1 and figure 2 is a perspective view showing a vacuum mixer according to the present invention, image 3 is a diagram showing the inside of a vacuum mixer according to an embodiment of the present invention, Figure 4 and Figure 5 is shown image 3 Diagram of the operating state of the inner cylinder drive part of the medium vacuum mixer.

[0036] Referring to the accompanying drawings, a vacuum mixer acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com