Piston driving assembly for oral care device and oral care device

A piston-driven, oral care technology, applied in the direction of the device for cleaning the dental cavity, can solve the problems of noise stress and unevenness, and achieve the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

application example 1

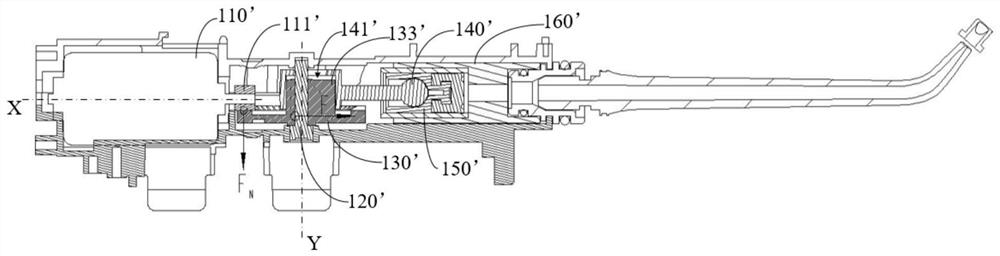

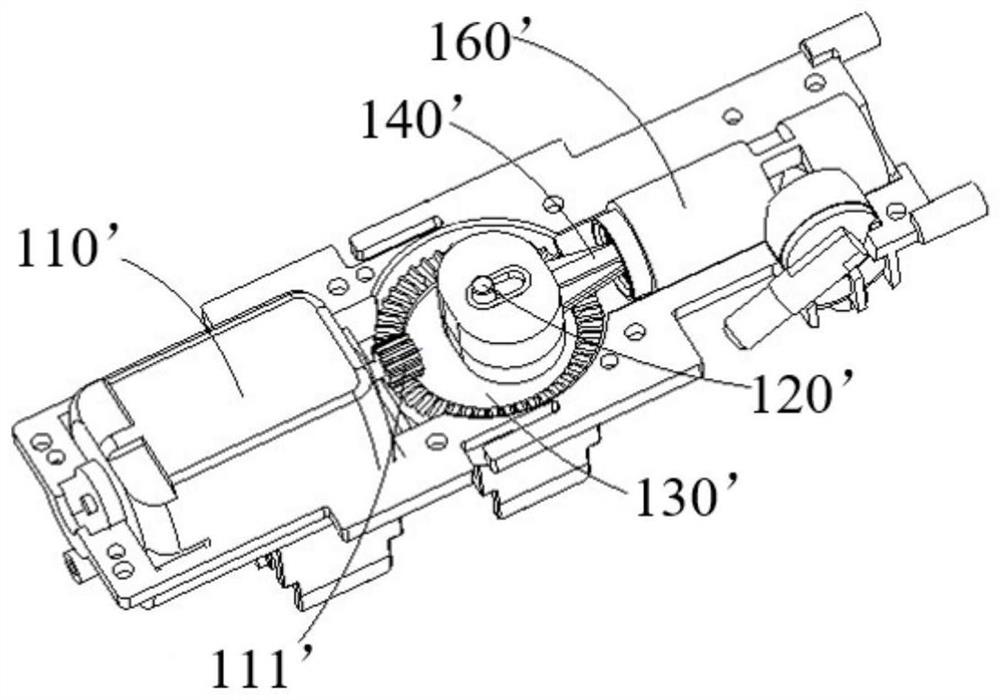

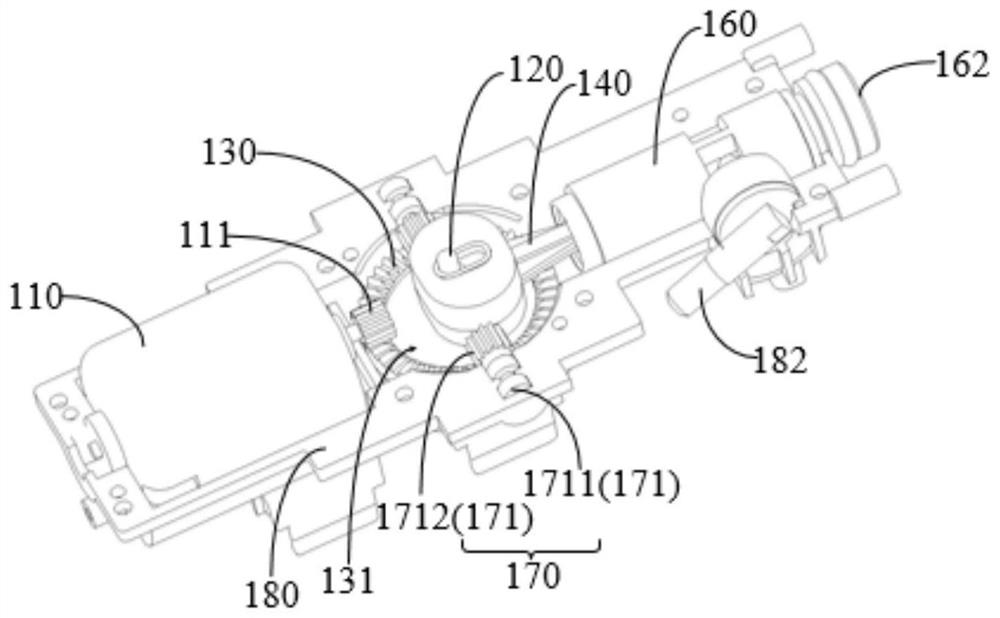

[0100] In application example 1, a piston driving assembly for an oral care device is provided, including a first gear 111, a connecting shaft 120, a second gear 130, a balance part 170, a transmission part 140 and a piston, the piston is a liquid part of the pump. The first gear 111 meshes with the second gear 130, the second gear 130 is rotatably fitted on the connecting shaft 120, and the first gear 111 has a first rotation axis, the second The gear 130 has a second axis of rotation, the first axis of rotation and the second axis of rotation being arranged at right angles. The balance member 170 is fitted to the second gear 130 , the transmission member 140 is eccentrically connected to the second gear 130 , and the piston is connected to the transmission member 140 .

[0101] When the first gear 111 rotates, the second gear 130 is driven to rotate, and drives the transmission member 140 and the piston to reciprocate. And taking the axis of the second gear 130 as a fulcru...

application example 2

[0103] In the second application example, a piston driving assembly for an oral care device is provided, which is different from the first application example in that the balance member 170 is specifically two pressing members 171 , and the two pressing members 171 It is matched with the first gear 111 at the first end 131 of the second gear 130, and forms three matching positions with the first end 131, and the three matching positions can determine a plane to ensure the first The first end 131 of the second gear 130 is located in a desired plane, so that the second gear 130 is not easily inclined.

application example 3

[0105] In Application Example 3, a piston driving assembly for an oral care device is provided, which is different from Application Example 1 in that the balance member 170 is specifically a support member 172 , and the second gear 130 has an opposite first gear 130 . One end 131 and a second end 132, the first gear 111 is engaged with the first end 131, the support 172 is supported on the second end 132, and the support 172 and the second gear A rolling fit is formed between 130 . The support 172 makes the second end 132 of the second gear 130 lie in a desired plane, so that the second gear 130 is not easily inclined. At the same time, the way of rolling fit makes the friction between the two less.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com