Low-cost fabric flaw detection system and method

A defect detection, low-cost technology, applied in the direction of image analysis, instruments, calculations, etc., can solve the problems of defect detection accuracy, accuracy impact, increase the workload of cloth inspectors, and cannot reduce labor costs, so as to improve accuracy and Its own robustness, solving the problem of fabric defect detection, improving performance and the effect of generalization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

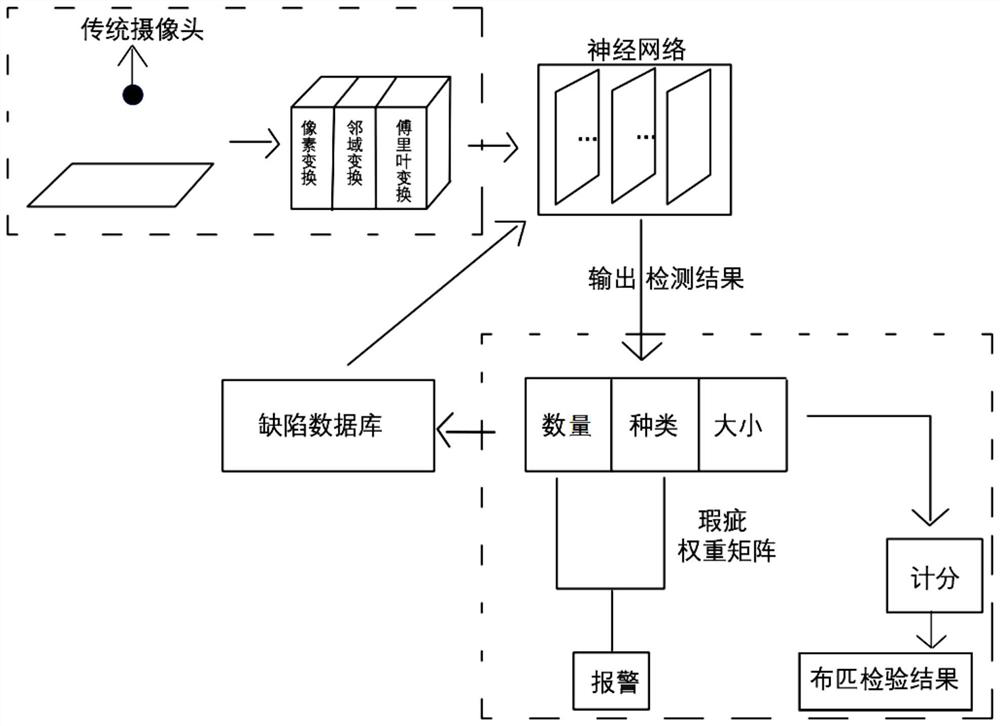

[0038] The invention designs a set of low-cost fabric defect detection system and method, realizes efficient and accurate labeling of fabric defects, and has multiple functions such as marking the position, quantity and type of defects. In addition, the system can accurately identify "fatal" defects and ordinary defects, provide alarms or shutdowns, so that managers can make timely corrections, thereby controlling fabric quality. Different from the detection equipment on the market that needs to rely on industrial cameras or infrared rays, the hardware of the fabric defect detection system only needs a traditional camera to achieve accurate and multi-functional defect detection, which greatly reduces the manufacturing cost of the detection equipment.

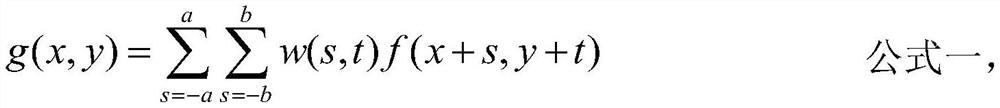

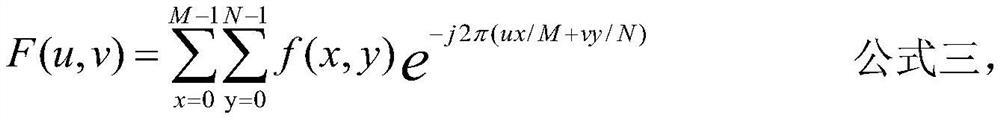

[0039] The entire workflow of the fabric defect detection system is: install the trad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com