Three-phase reactor on-load switch clamping potential structure and reactor

A technology of three-phase reactors and reactors, which is applied in the field of reactors, can solve problems such as neutral point breakdown damage switches, and achieve the effect of protecting switches and preventing discharge breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

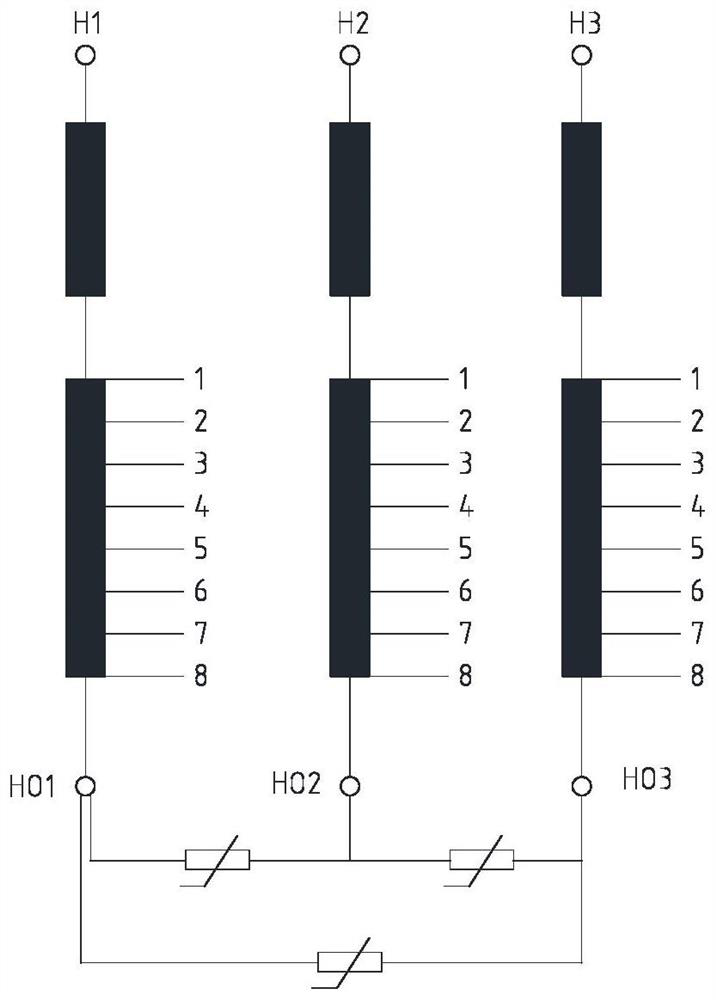

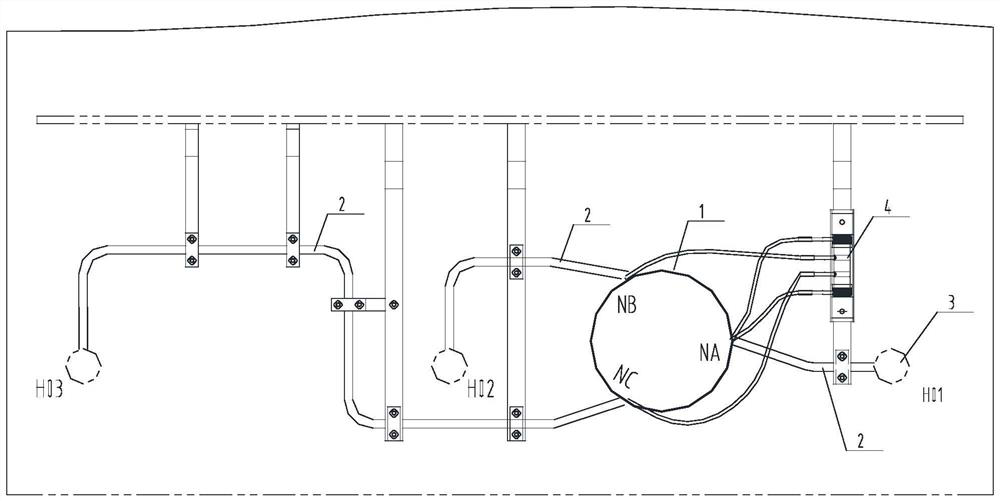

[0022] The invention discloses a structure for clamping potential of a three-phase reactor on-load switch, specifically as follows: figure 1 and figure 2 As shown, the structure includes:

[0023] A potential clamping component is added between the three neutral points of the on-load switch 1 of the reactor.

[0024] In some embodiments, the potential clamping component adopts a ZnO valve plate 4 .

[0025] In some embodiments, the number of the ZnO valve plates 4 is set according to the set on-voltage.

[0026] In some embodiments, the ZnO valve plates 4 are equally divided into three groups, and two ends of each group are respectively connected in parallel with the three-phase neutral point terminals of the on-load switch 4 .

[0027] In some embodiments, the ZnO valve plates 4 are evenly divided into three groups, one group of ZnO valve plates 4 for each phase in the three-phase neutral point, and four terminals are drawn out, and one group is connected between the neut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com