Oil-immersed sensor for locomotive

A sensor and locomotive oil technology, applied in instruments, measuring devices, electrical devices, etc., can solve the problems of limited use range, no sparks, poor safety, etc., to achieve stable and reliable output signals, ensure contact reliability, and improve use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

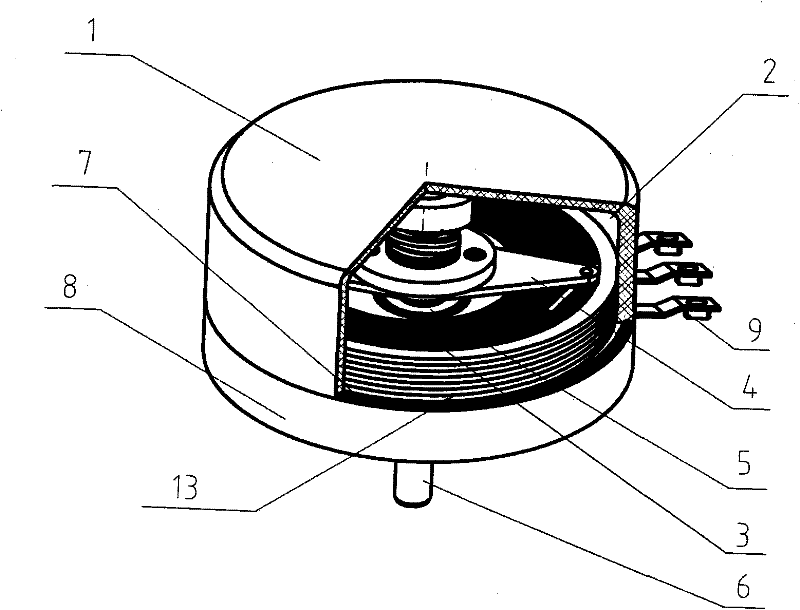

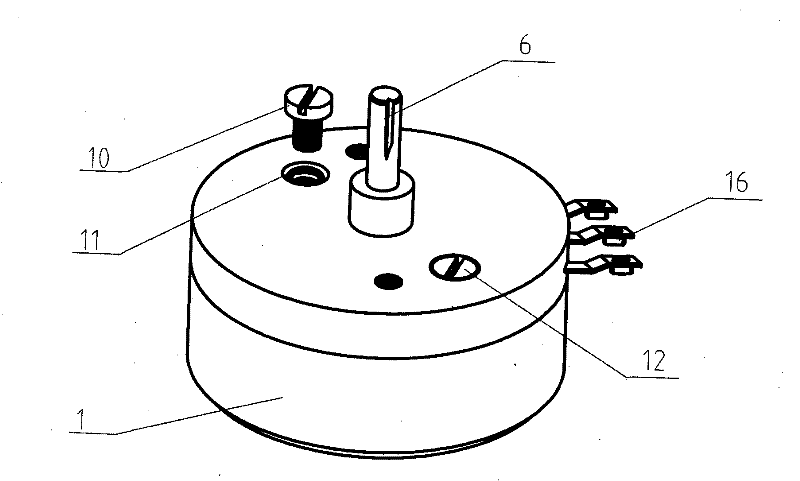

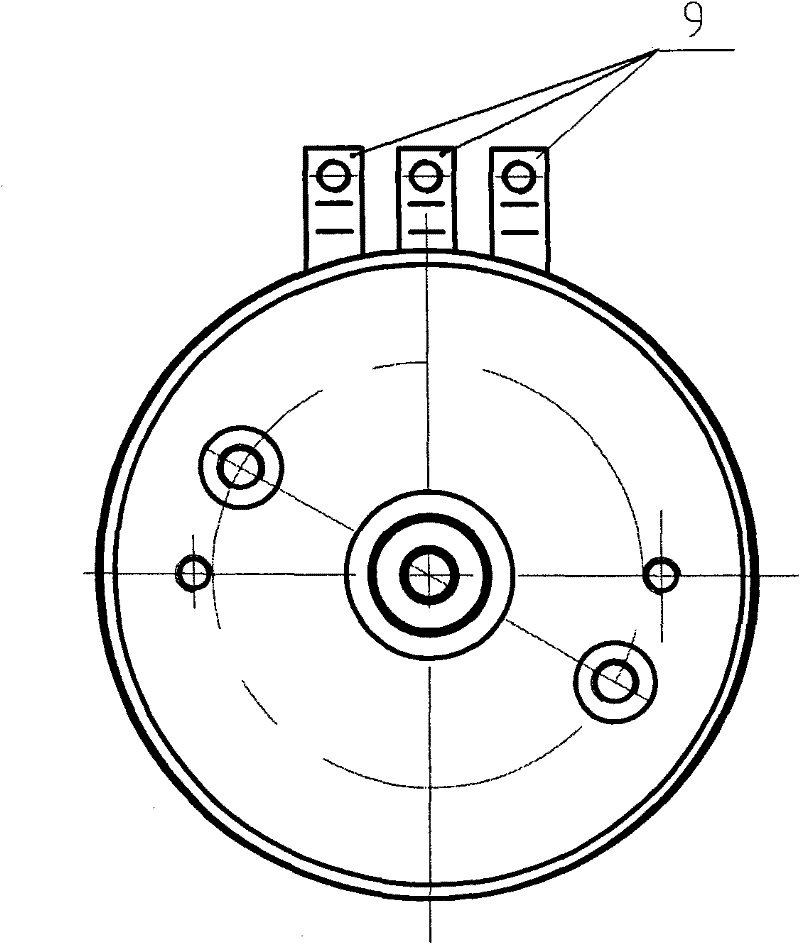

[0018] This embodiment is composed of an angular displacement conductive plastic sensor, and the angular displacement conductive plastic sensor is composed of three parts: a housing part, a rotating shaft part and a resistor body part. The casing part includes a casing 8 and a casing 1 with a lead-out end 9 connected thereto. The casing 1 is connected with the casing 8 through a thread 13 to form a sealed space, and the O-shaped first sealing ring 7 Sealed, built-in shaft parts and resistor body parts, the sealed space is filled with special oil. The housing 8 is a stainless steel 14 outer cover, and the inner frame is integrally inlaid with a transparent plastic 15, so that internal oil can be seen. There are three lead-out ends 9 on the cover, threaded flanges 16 are formed on the mounting holes of the lead-out ends 9, bearing holes are set on the top of the housing 8, and rubber-plastic composite oil seal rings 5 are installed inside, and the rotating shaft 6 of the rotat...

Embodiment 2

[0020] There are four flat M3 threaded flanged outlets 9 on the cover, one of which is set on the central axis, the other two are symmetrically arranged on both sides, and the other is used for grounding and is connected to the center of the circle of the outlets set on the central axis. The included angle is 45 degrees. Other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com