Electron-emitting device, method of manufacturing the same, electron source, and image display apparatus

A technology of electron emission and manufacturing method, applied in the direction of image/graphic display tube, electrode system manufacturing, discharge tube/lamp manufacturing, etc., which can solve the problems of reduced electron emission efficiency and inability to set sufficient gaps, etc., and achieve low power consumption , Prevent leakage current generation, high brightness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, a detailed description will be given of preferred embodiments of the present invention for purposes of explanation while referring to the accompanying drawings. Note that dimensions, materials, shapes, relative positions, and the like of components described in the embodiments are not intended to limit the scope of the present invention to the given examples unless specifically mentioned otherwise.

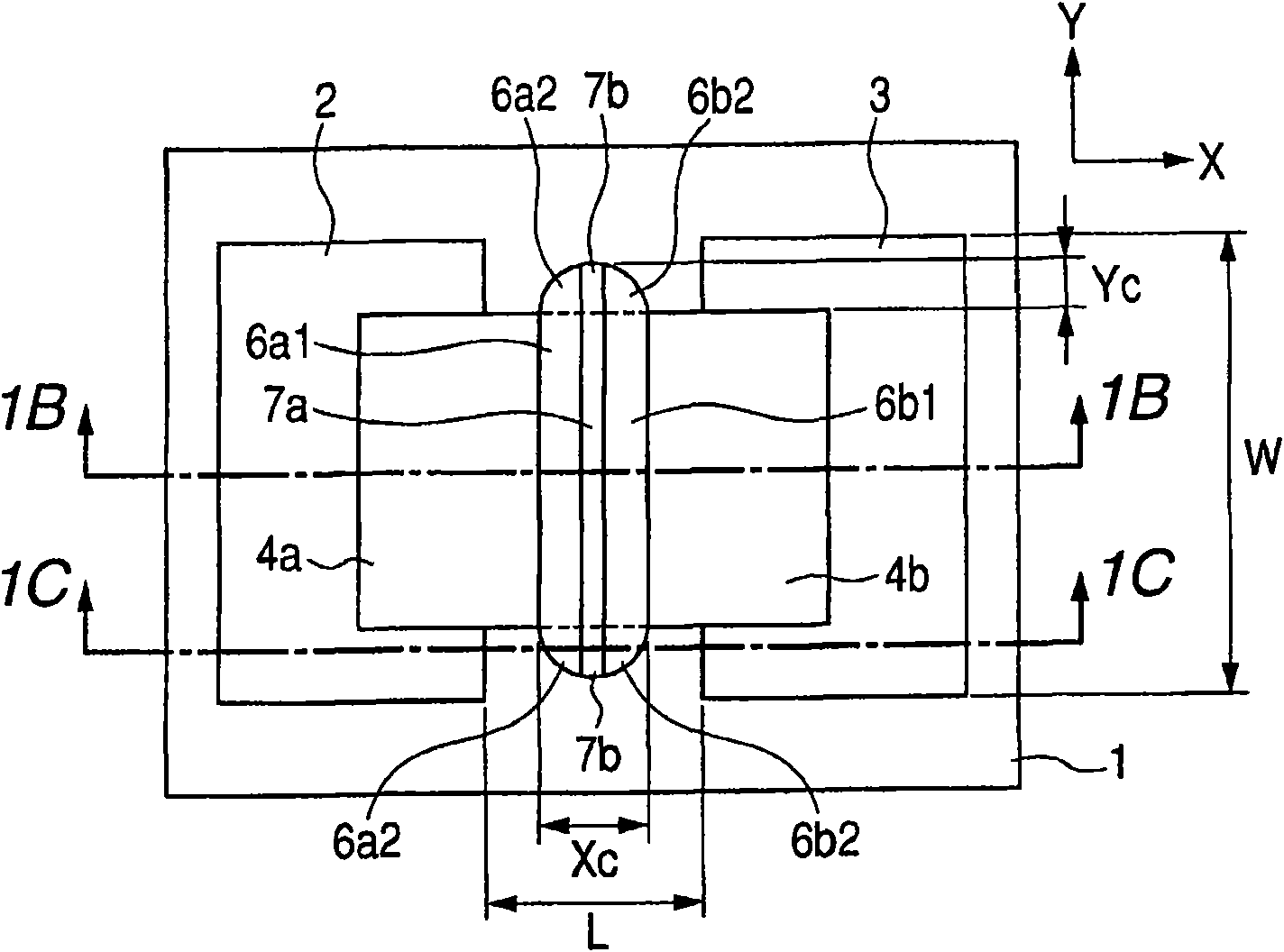

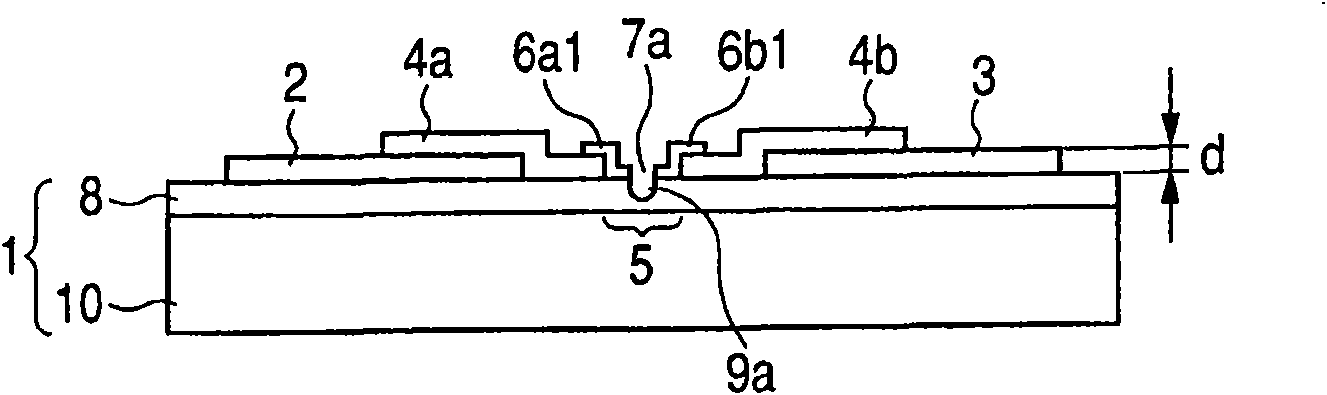

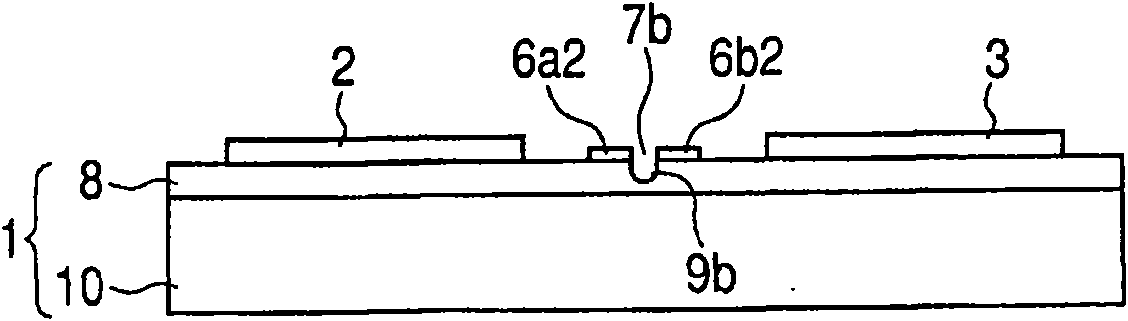

[0027] Figure 1A ~ 1C is a schematic diagram showing an electron-emitting device according to an embodiment of the present invention. Figure 1A is the floor plan. Figure 1B is along Figure 1A Cross-sectional view of line 1B-1B. Figure 1C is along Figure 1A A cross-sectional view of the 1C-1C line.

[0028] Figure 1A ~ 1C A structure in which a first electrode 2 connected to a first conductive film 4 a and a second electrode 3 connected to a second conductive film 4 b are provided on a substrate 1 is shown. However, when the first conductive film 4a a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com