Moving magnetic suspension type multi-wheel transmission device

A multi-wheel drive and magnetic levitation technology, applied in electromechanical devices, electric components, permanent magnet clutches/brakes, etc., can solve the problems of large wear, reduction and low power generation efficiency of contact transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

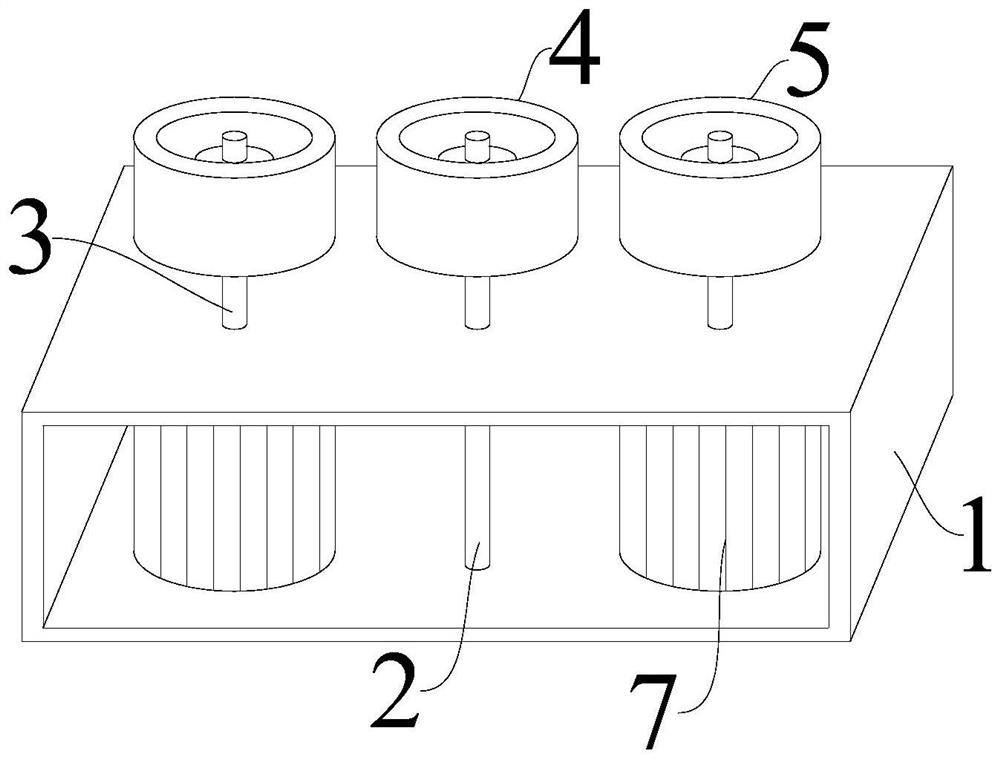

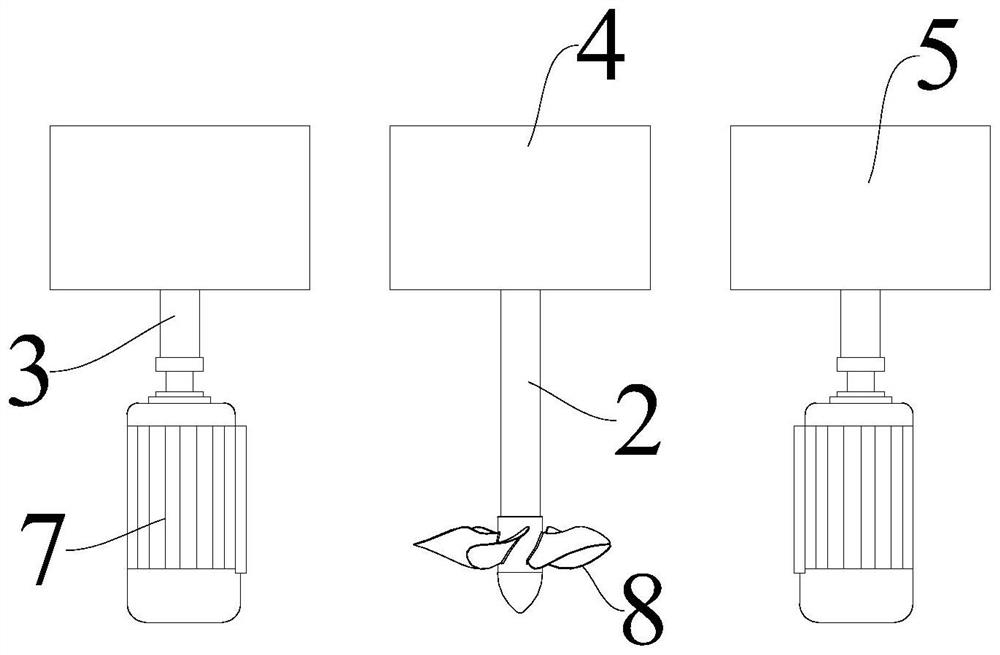

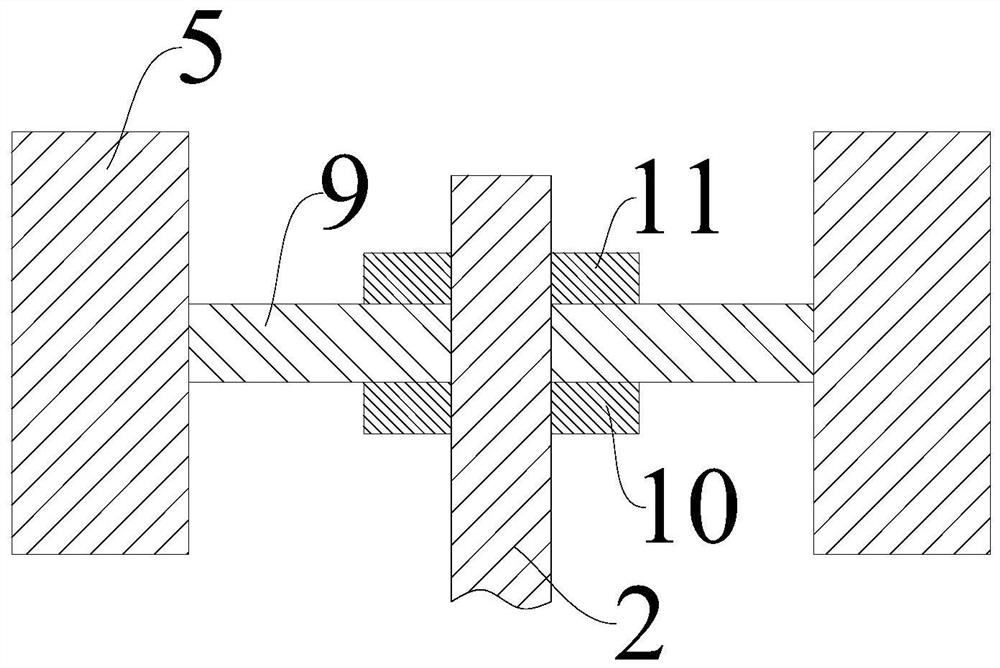

[0038] Please refer to Figure 1-Figure 3 , figure 1Shown is a schematic structural diagram of the induced magnetic suspension type multi-wheel transmission provided in Embodiment 1 of the present invention; figure 2 Shown is the front view of the induced magnetic suspension type multi-wheel transmission provided by Embodiment 1 of the present invention; image 3 Shown is a partial cross-sectional view of the position of the driving magnetic wheel 4 provided in Embodiment 1 of the present invention.

[0039] This embodiment provides a driving magnetic levitation type multi-wheel transmission device, which includes an installation frame 1, the installation frame 1 is rotatably provided with a drive shaft 2 and a driven shaft 3, and the drive shaft 2 is detachably provided with a drive magnetic wheel 4. The driven shaft 3 is detachably provided with a driven magnetic wheel 5 . The driving magnetic wheel 4 is spaced from the driven magnetic wheel 5 .

[0040] The above-mentio...

Embodiment 2

[0047] Please refer to Figure 4 , Figure 4 Shown is a schematic structural diagram of the induced magnetic suspension type multi-wheel transmission provided in Embodiment 2 of the present invention.

[0048] The difference between this embodiment and Embodiment 1 is that when the driven magnetic suspension multi-wheel transmission device needs to be used for transmission, the mounting frame 1 is provided with a driving motor 6 , and the driving shaft 2 is provided on the transmission shaft of the driving motor 6 .

[0049] At this time, the above-mentioned driving shaft 2 is driven to rotate by the driving motor 6, and the driving shaft 2 drives the driving magnetic wheel 4 to rotate; because the magnetic pole of the outer side wall of the above-mentioned driving magnetic wheel 4 is the same as the magnetic pole of the outer side wall of the above-mentioned driven magnetic wheel 5, the rotating The driving magnetic wheel 4 drives the driven magnetic wheel 5 to rotate, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com