Wireless power-taking logistics sorting system

A sorting system and wireless technology, applied in sorting, electric vehicles, electrical components, etc., can solve problems that easily affect equipment operation, reduce equipment reliability and operating efficiency, accelerate aging, etc., to ensure the quality of wireless power transmission. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

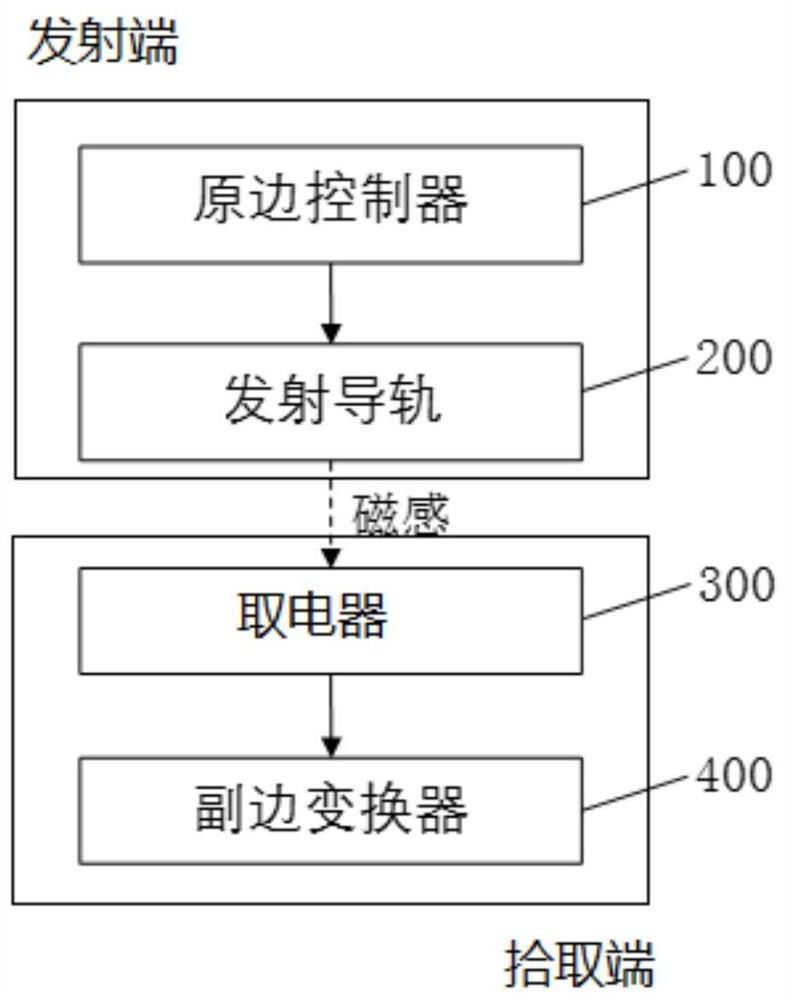

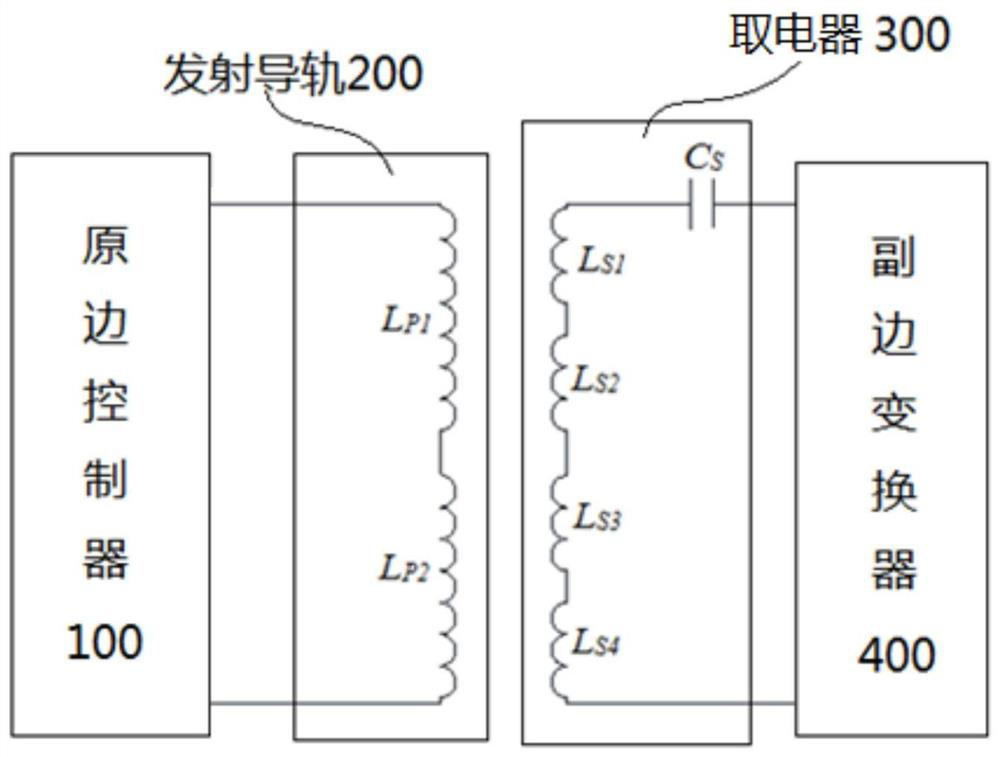

[0027] This embodiment provides a wireless power-taking type logistics sorting system, such as figure 1 As shown, it includes a transmitting end and a picking end, wherein the transmitting end includes the primary side controller 100 electrically connected, the transmitting guide rail 200, and the transmitting guide rail 200 is installed on the movement track of the sorter tray, and at least one section of the transmitting guide rail transmits energy. The segments are arranged along the movement path of the sorter tray. In this embodiment, the launch rail 200 is wound into a double-wire type by a single excitation wire, and the opposite line segments (the first launch rail and the second launch rail) on the left and right sides are used as the energy. transmission segment.

[0028] The pick-up end includes a pickup 300 and a secondary side converter 400 that are electrically connected. The pickup 300 includes a first receiving coil and a second receiving coil connected in seri...

Embodiment 2

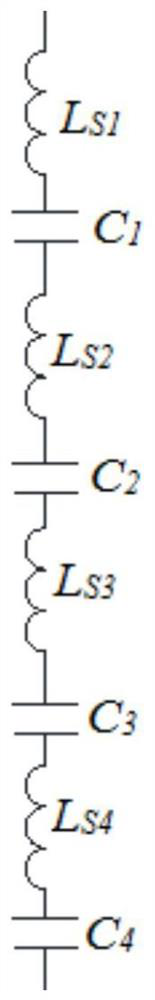

[0057] The difference between this embodiment and Embodiment 1 is that the launch rail 200 is embedded under the ground and separated by the ground, which can ensure the smoothness of the ground. Correspondingly, the circuit structure of this embodiment is as follows Image 6 As shown, compared with Embodiment 1, only two series-connected transmitting coils with different winding directions are used, which are denoted as L S1 ’ and L S2 ’, and similarly, also set the resonant capacitor C in series with the transmitting coil S ’. In this embodiment, as Figure 7 shown, the resonant capacitor C S ' by the capacitor array C 1 ' and C 2 ' composition, respectively with the transmitter coil L S1 ’ and L S2 ' concatenate. corresponds to Image 6 , 7 circuit design, see Figure 8 , an exploded view of the structure of the electrical fetching device 300 used in this embodiment, it can be seen that the electrical fetching device 300 is designed in a plane shape, and the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com