A flexible hinge ultrasonic bearing

A technology of flexible hinges and bearings, applied in bearings, shafts and bearings, mechanical equipment, etc., can solve the problems that gas extrusion film lubrication is in the laboratory stage, the project has not been applied, and is immature, etc., to achieve non-contact transmission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

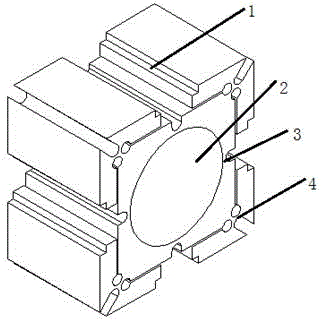

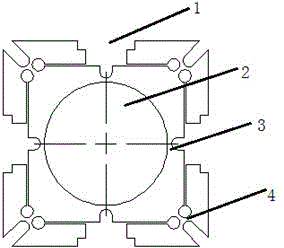

[0023] Please refer to Figure 1 to Figure 6 As shown, the flexible hinge ultrasonic bearing of the present invention includes: 4 piezoelectric ceramic slots 1 , a round hole 2 , 4 single-arc flexible hinges 3 and 12 double-arc flexible hinges 4 . The flexible hinge ultrasonic bearing of the present invention is in the shape of a cube, and the flexible hinge ultrasonic bearing includes four surfaces extending along the front and rear directions, four piezoelectric ceramic slots 1 are respectively formed on the four surfaces, and the circular holes 2 extend along the front and rear directions , four piezoceramic slots 1 surround the round hole 2, of which the four single-arc flexible hinges are formed by four semi-circular grooves with a diameter of Φ3 evenly distributed along the round hole and the round hole, and 12 double-arc flexible hinges Every three hinges are evenly distributed on the vertical line of the positions of the two single-arc flexible hinges.

[0024] The ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com