Sliding block mold opening and closing sequence control structure

A technology of sequential control, mold opening and closing, applied in the field of slider opening and closing mold sequence control structure, which can solve the problems of slider scratches, easy scratches, and burrs on product 10, so as to avoid scratches and burrs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to have a further understanding of the purpose, technical effect and technical means of the present invention, the following detailed description is now given in conjunction with the accompanying drawings.

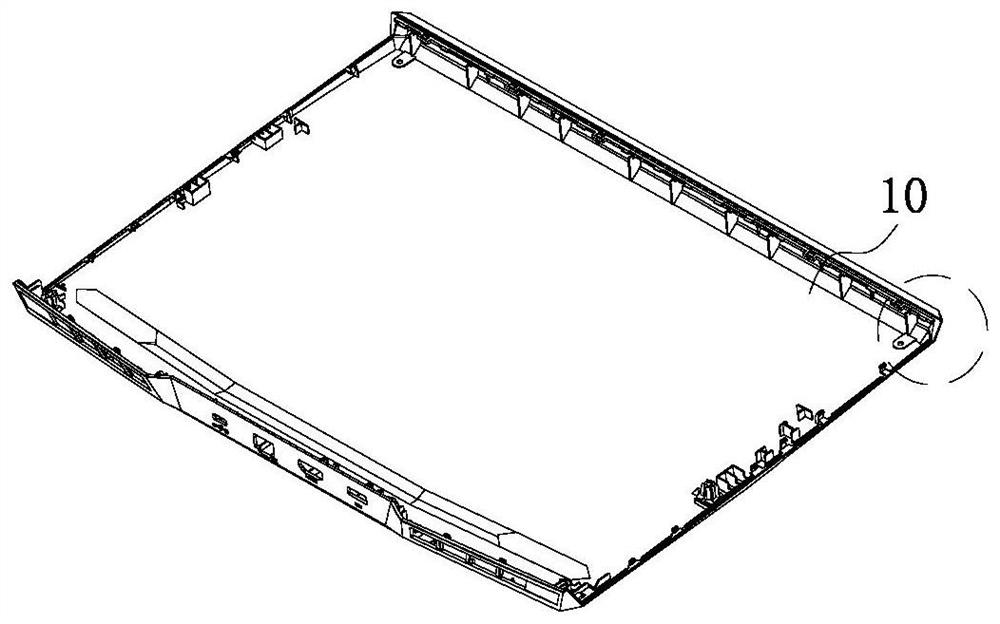

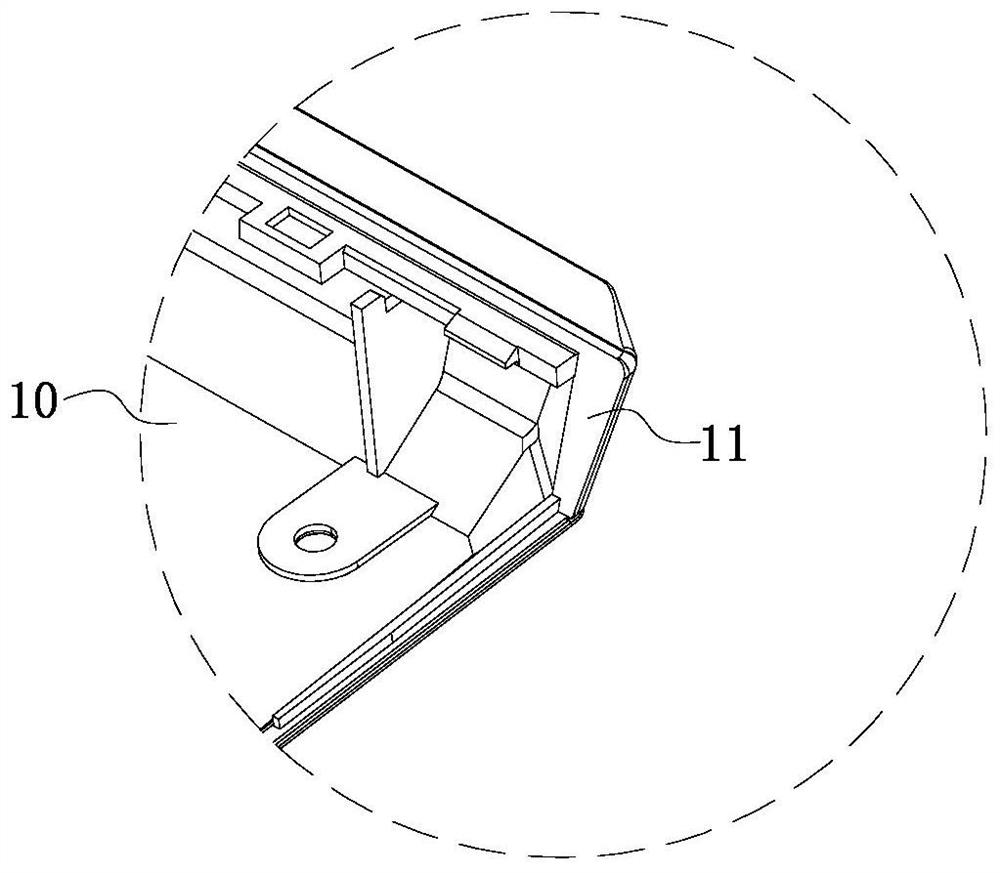

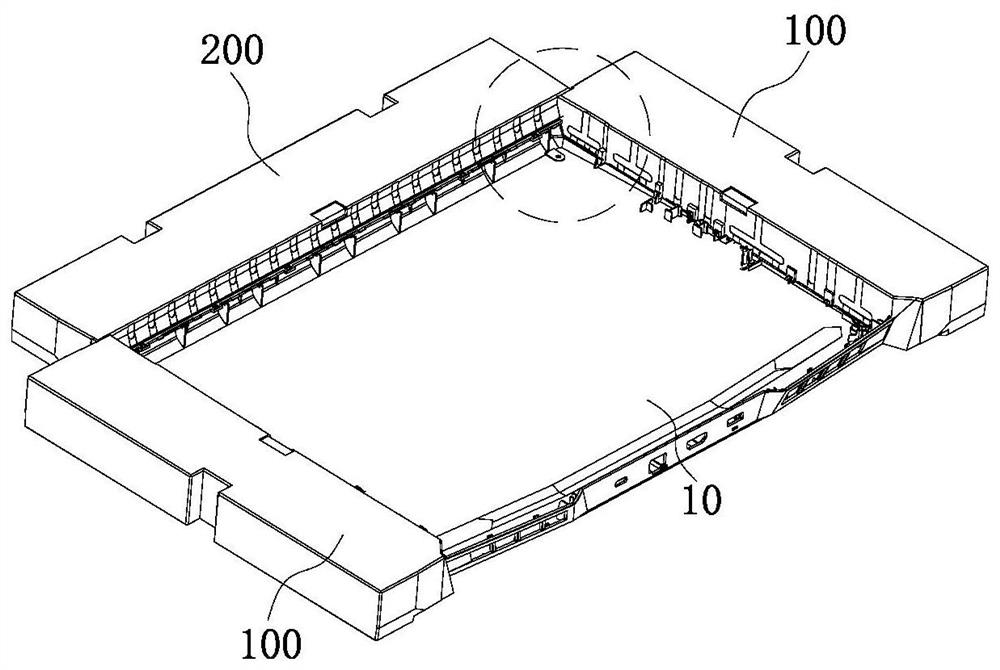

[0025] see image 3 , Image 6 and Figure 7 shown, where image 3 A three-dimensional schematic diagram of the slider opening and closing sequence control structure of the present invention is shown when a product is formed, Image 6 A schematic diagram showing an angle of the slider opening and closing sequence control structure in the mold of the present invention, Figure 7 A schematic diagram of another angle in the mold of the slider opening and closing sequence control structure of the present invention is shown.

[0026] The present invention provides a sliding block mold opening and closing sequence control structure, which is applied to the molding product 10 in the mold. 11 is the interface between two sliders forming adjacent sides, the mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com