Mechanical arm cutting guide rail for manufacturing industrial automatic control device

A technology of automatic control device and mechanical arm, which is applied in the direction of manufacturing tools, sawing machine devices, sawing machine accessories, etc. It can solve the problems of material misalignment, inconvenient operation, and sudden drop in stress intensity, so as to achieve high efficiency and improve production safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

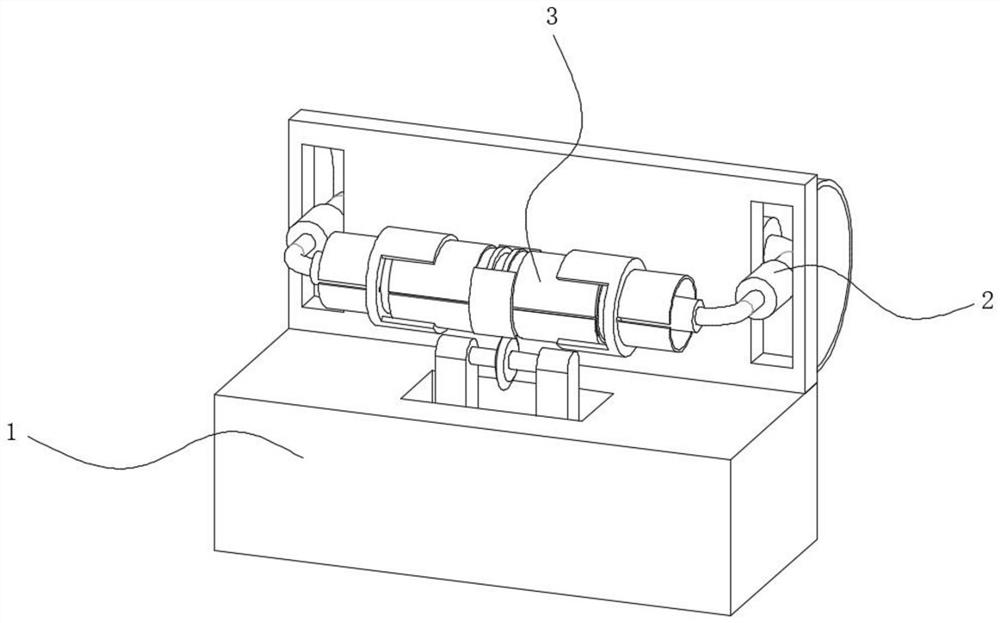

[0029] see Figure 1-Figure 5 , the present invention provides a technical solution: a mechanical arm cutting guide rail for manufacturing an industrial automatic control device, comprising a cutting box 1, a vertical frame plate is fixedly connected to the back of the upper surface of the cutting box 1, and the back of the upper surface of the cutting box 1 passes through A supporting device 2 is fixedly connected to the vertical frame plate, and a fixing device 3 is arranged in the middle of the supporting device 2 .

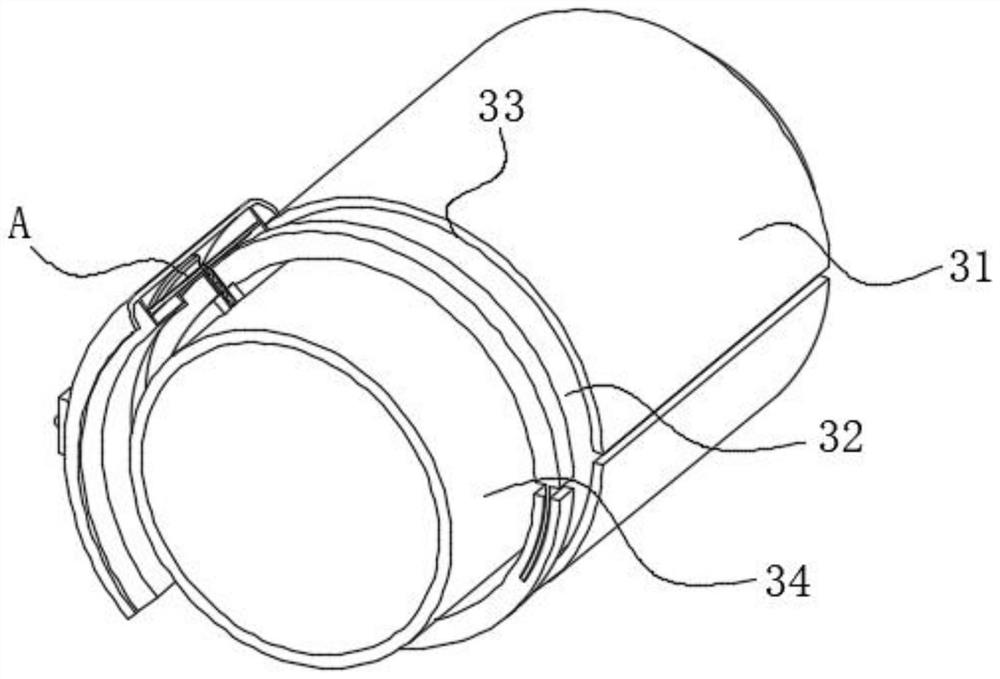

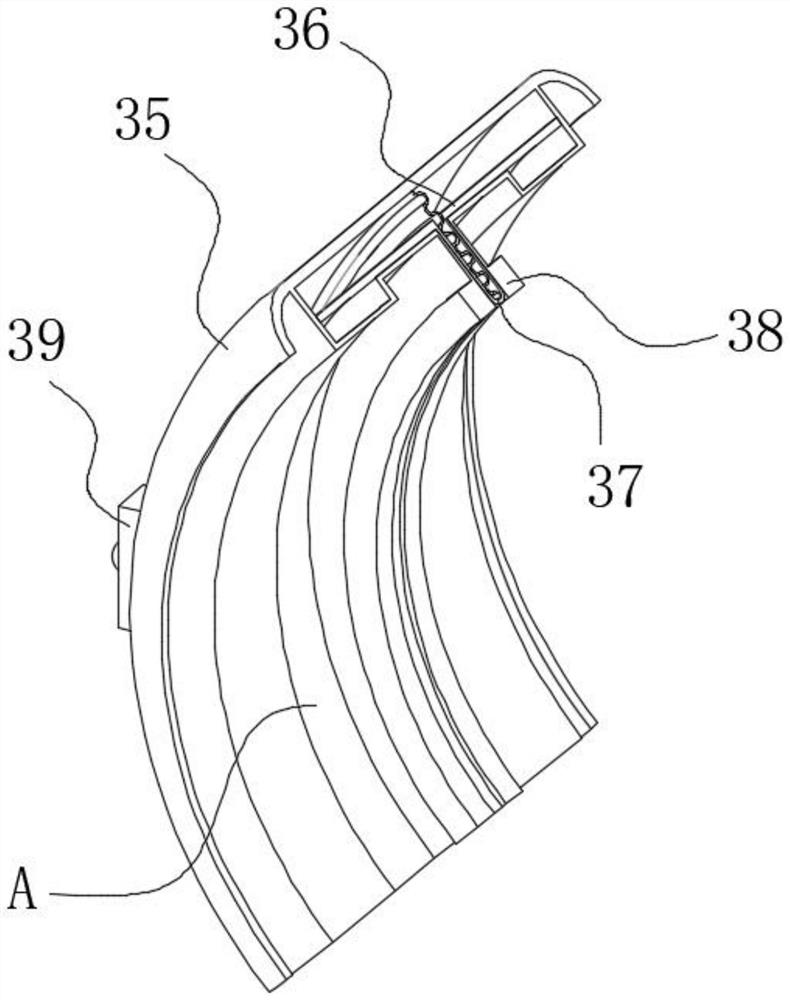

[0030] The fixing device 3 includes a half-split rotating drum 31 , the inner cavity of the half-split rotating drum 31 is fixedly connected with an inner clamping plate 32 , the left and right sides of the half-split rotating drum 31 are symmetrically provided with annular grooves 33 , and the outer surface of the half-split rotating drum 31 is provided with an annular groove 33 . Sliding outer plates 35 are symmetrically arranged on the front and rear sides ...

Embodiment 2

[0041] see Figure 1-Figure 7 , the present invention provides a technical solution: on the basis of the first embodiment, a robotic arm cutting guide rail for manufacturing an industrial automatic control device includes a cutting box 1, and a vertical frame plate is fixedly connected to the back of the upper surface of the cutting box 1, A support device 2 is fixedly connected to the back of the upper surface of the cutting box 1 through a vertical frame plate, and a fixing device 3 is arranged in the middle of the support device 2 .

[0042]The fixing device 3 includes a half-split rotating drum 31 , the inner cavity of the half-split rotating drum 31 is fixedly connected with an inner clamping plate 32 , the left and right sides of the half-split rotating drum 31 are symmetrically provided with annular grooves 33 , and the outer surface of the half-split rotating drum 31 is provided with an annular groove 33 . Sliding outer plates 35 are symmetrically arranged on the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com