Spiral winding robot

A helical winding and robot technology, applied in the direction of manipulators, manufacturing tools, chucks, etc., can solve the problems of small grasping range, slow movement speed, small load, etc., and achieve the effect of large grasping load and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

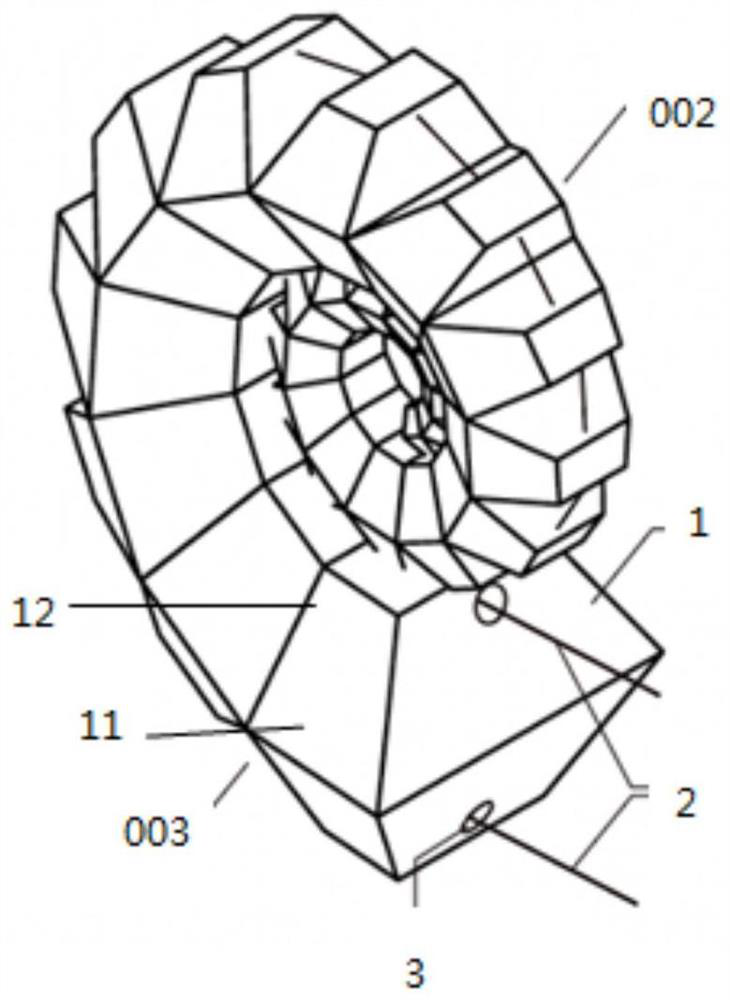

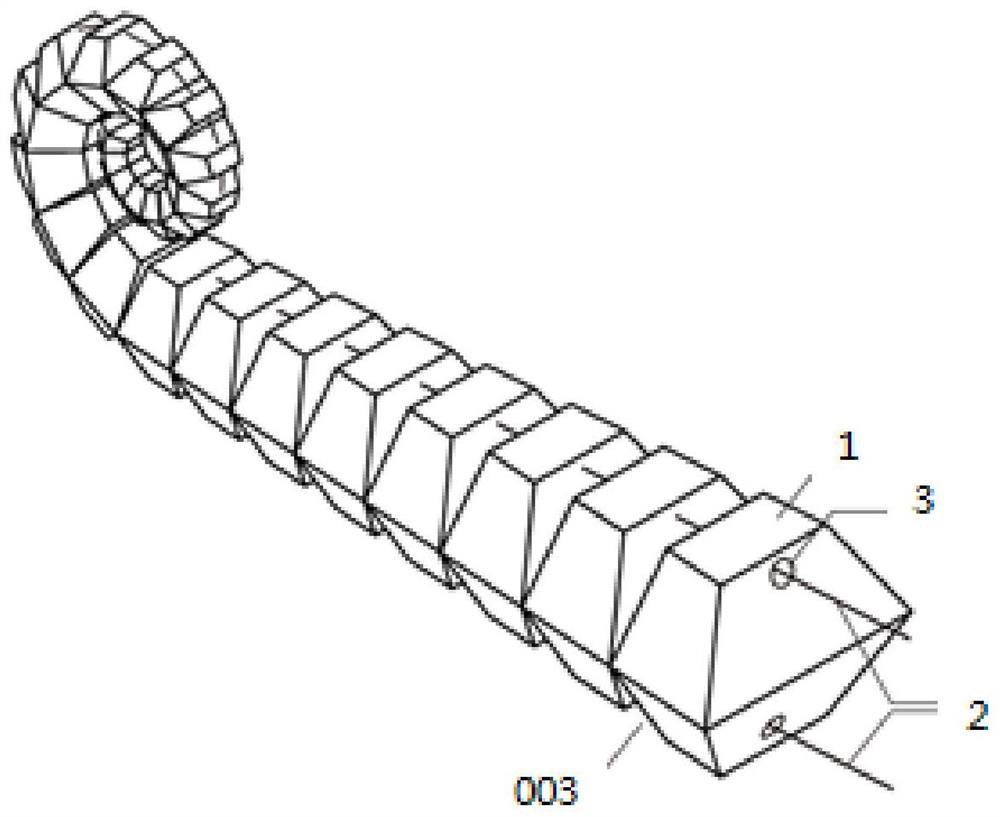

[0047] like Figures 2 to 4 As shown in the figure, a spiral winding robot is used as the end effector of the robot to grab objects, which specifically includes: a main body and a driving mechanism; the driving mechanism drives the main body itself to form one or more sets from an extended state and tight winding. Convert between connected isometric spirals, unfold to drop items or wrap to grab items.

[0048] For the convenience of description, where it is not individually emphasized that it is tightly wound to form a set of equiangular spirals, it can be understood as one or more sets of connected equiangular spirals.

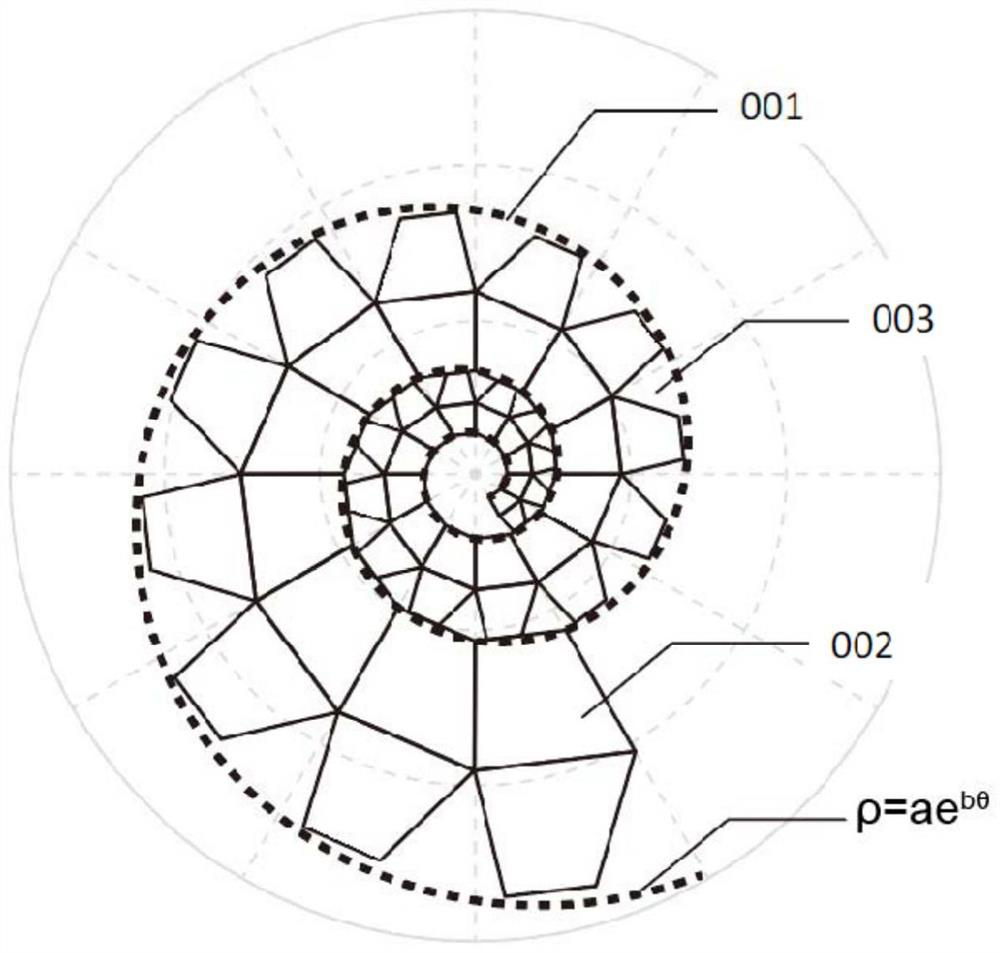

[0049] In this example, the body includes a plurality of helical unit segments 1, where the helical unit segment 1 is designed by discretizing the isometric helix 001 to obtain the size of the discrete unit longitudinal section 002, so it can ensure tight After winding, it forms an isometric spiral. Specifically, the longitudinal thickness dimension of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com