Substrate having metal layer and manufacture method for the same

A manufacturing method and metal layer technology, applied in printed circuit manufacturing, electrical components, printed circuits, etc., can solve the problems of high cost, poor insulation, poor accuracy, etc., and achieve improved product cost performance, improved production efficiency, and stable production processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The preferred embodiments of the invention will be further described in detail below.

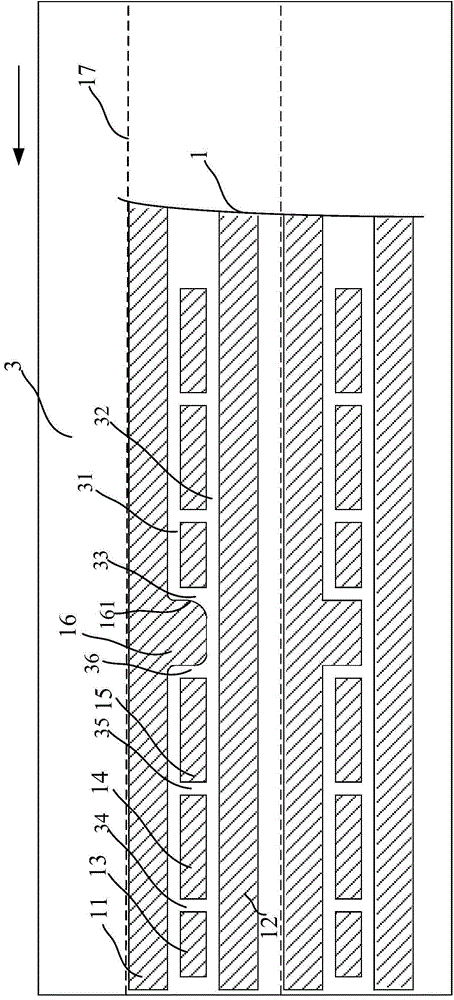

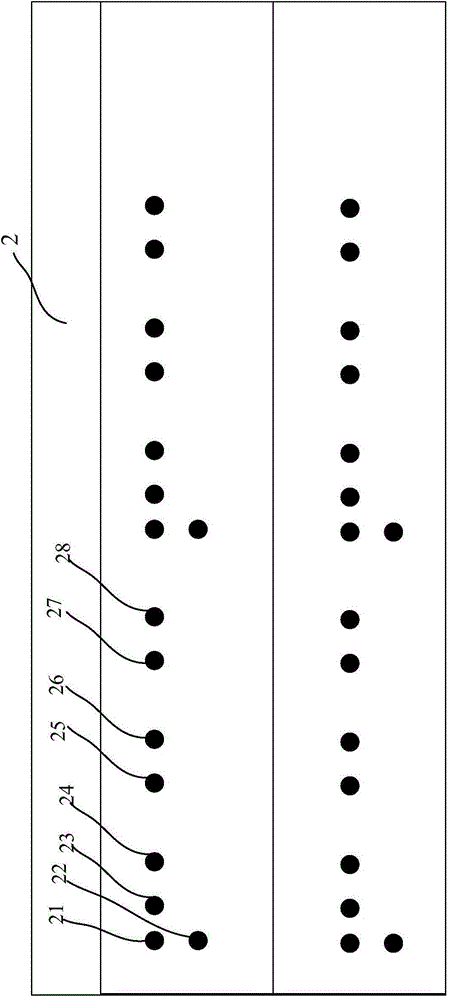

[0050] Such as Figures 1 to 3 Shown, a kind of manufacturing method of the substrate with metal layer is characterized in that, comprises the following steps:

[0051] S1, sticking a layer of metal film on the insulating film substrate 3 .

[0052] The film substrate 3 may be PET (polyethylene terephthalate, polyethylene terephthalate). In some embodiments, the film substrate 3 may have a hot-melt adhesive layer, and the hot-melt adhesive layer is adhered to the metal film at high temperature. Common copper foil can be used for the metal film.

[0053] S2, cutting dividing lines on the metal film, and forming dividing regions between adjacent dividing lines.

[0054] Such as figure 2 As shown, a cutting line can be cut on the metal film by using a cutter, and the dividing areas 31 and 32 are formed between the dividing lines.

[0055] S3, separating the metal thin film strips...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com