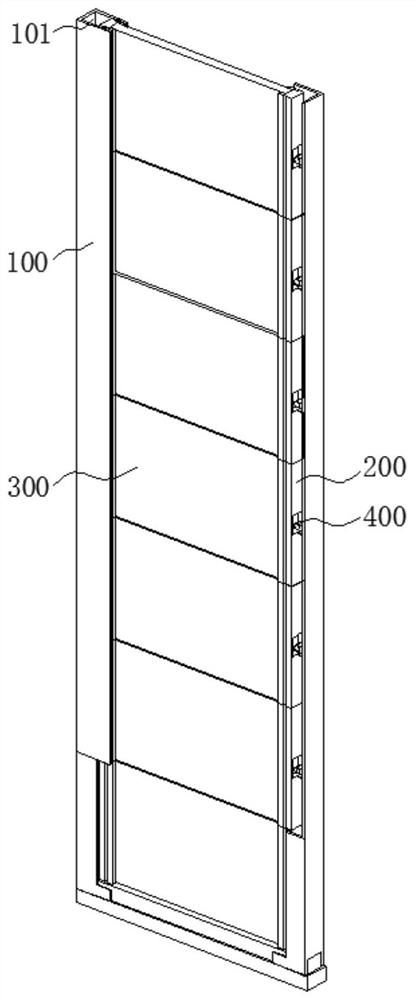

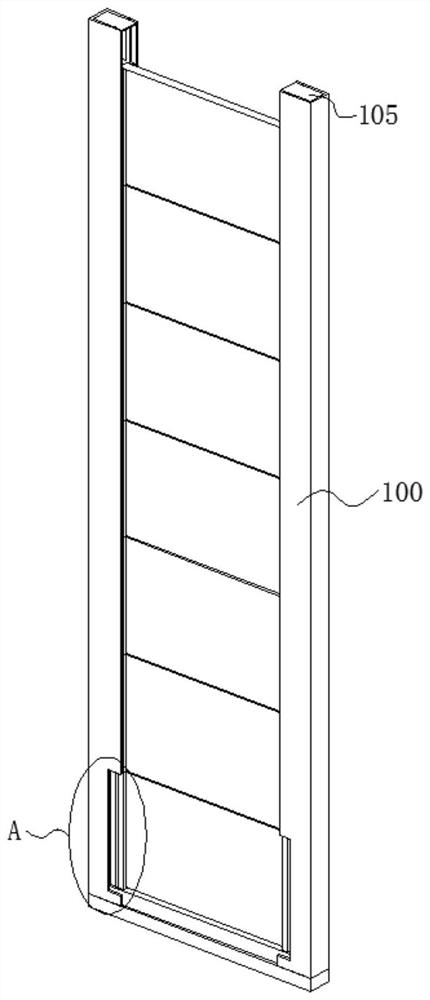

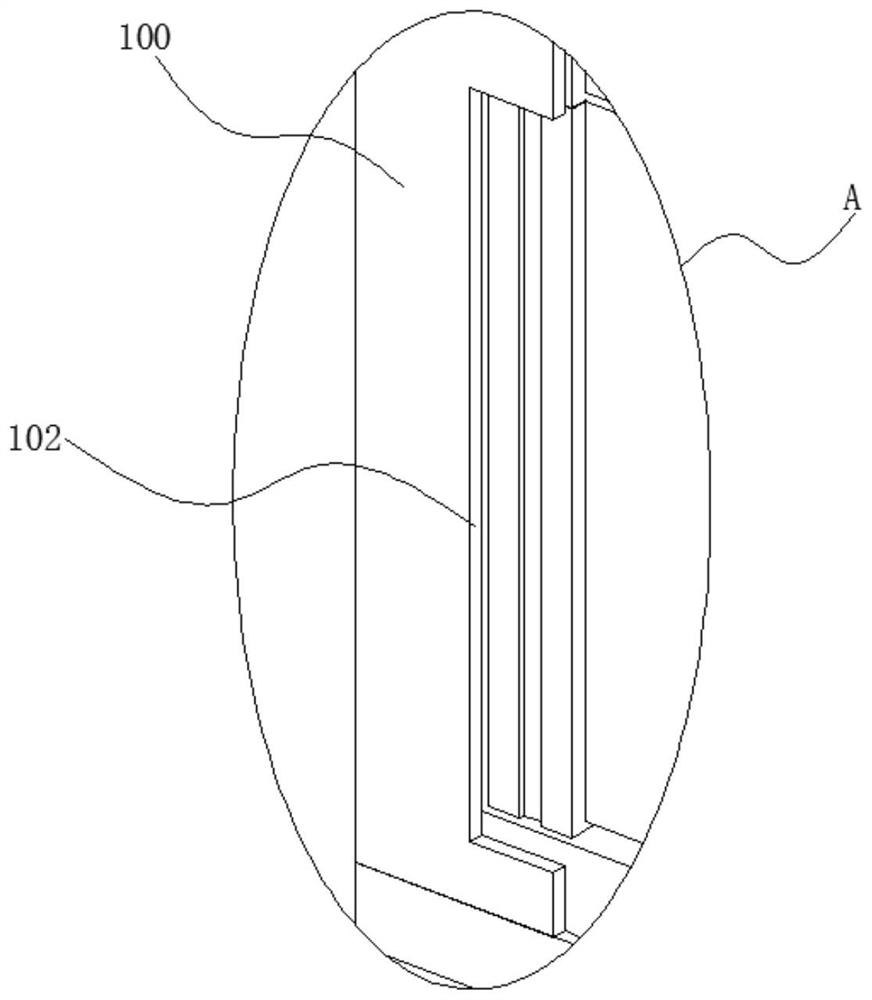

Assembly type curtain wall structure capable of being efficiently installed and installation method thereof

A prefabricated, curtain wall technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of inconvenient high-level installation, poor operation efficiency, etc., to enhance the installation effect, reduce the installation difficulty and construction labor. Strength, inconvenience-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to understand the features and technical contents of the embodiments of the present disclosure in more detail, the implementation of the embodiments of the present disclosure will be described in detail below with reference to the accompanying drawings, which are for reference only and are not intended to limit the embodiments of the present disclosure. In the following technical description, for the convenience of explanation, numerous details are provided to provide a thorough understanding of the disclosed embodiments. However, one or more embodiments may be practiced without these details. In other instances, well-known structures and devices may be shown simplified in order to simplify the drawings.

[0033] The terms "first", "second" and the like in the description and claims of the embodiments of the present disclosure and the above-mentioned drawings are used to distinguish similar objects, and are not necessarily used to describe a specific order or s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com