Tower tube internal part welding-free column lapping testing mechanism

A testing mechanism, no welding technology, used in the testing of mechanical parts, the testing of machine/structural parts, measuring devices, etc., can solve the problems of inconvenient welding, affecting the stability of the installation structure, lack of testing equipment, etc., to improve the test effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

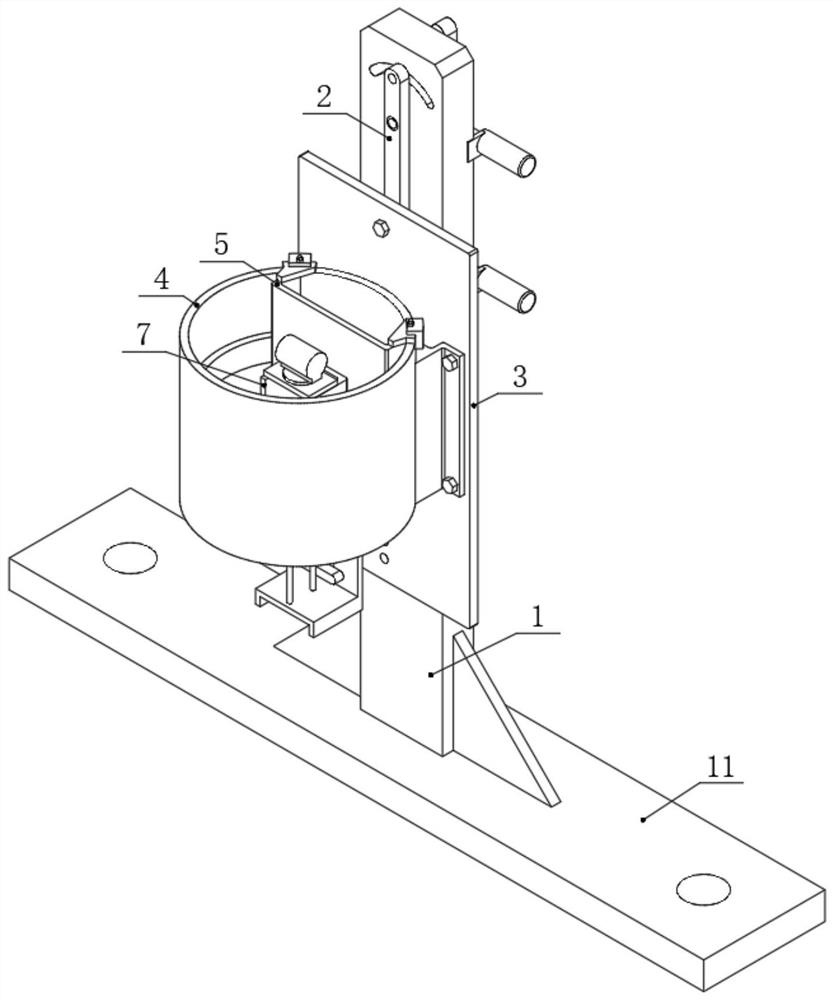

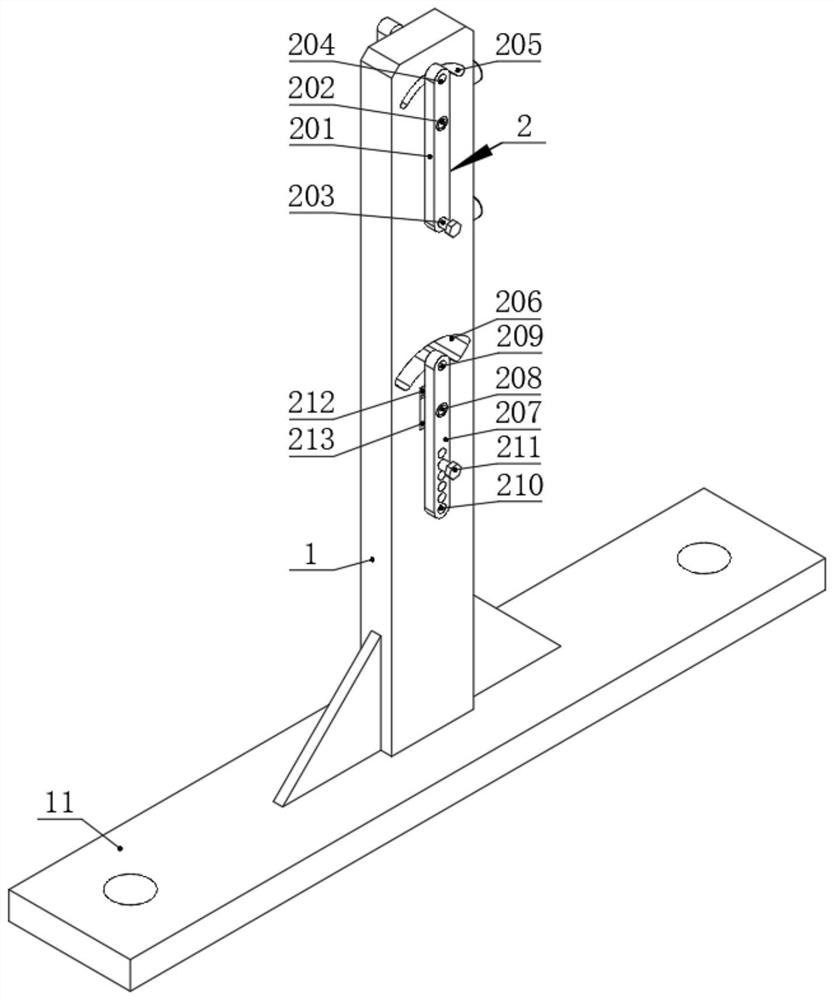

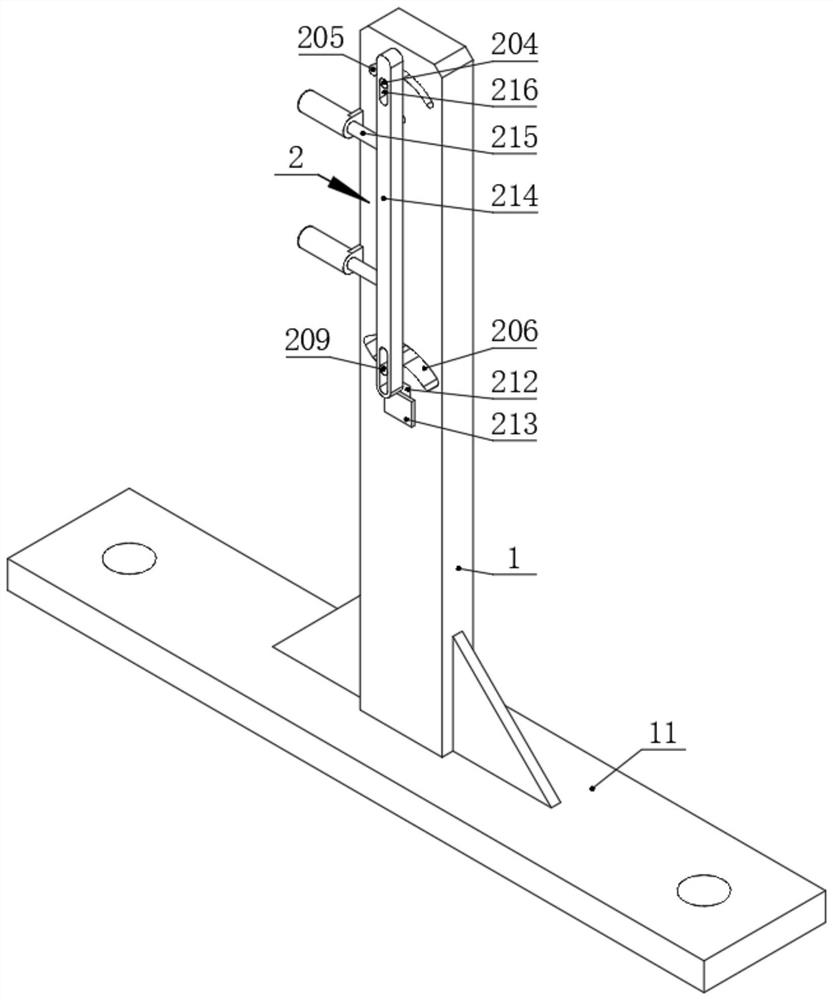

[0028] In this embodiment, a test mechanism for the non-welded lap column of the tower inner parts, please refer to figure 1 , Figure 5, including a vertical plate 1 and a bottom plate 11, the vertical plate 1 is vertically fixed on the bottom plate 11, an adjustable swing simulation mechanism 2 is installed on the vertical plate 1, and the swing end of the adjustable swing simulation mechanism 2 A swinging plate 3 is installed on the upper surface, a cylinder 4 is fixedly installed on the front of the swinging plate 3, a connecting plate 5 is installed in the cylinder 4, and a front surface of the connecting plate 5 is fixedly installed with a self-positioning fixing mechanism 6. Column 7, a vertical loading mechanism 8 is fixedly installed at the bottom of the column 7, a vibration motor 10 is installed on the top of the column 7, and the bottom end of the vertical loading mechanism 8 is connected to the connection plate 5. The bottom is fixedly connected, a swing loading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com