Preheating method before friction stir welding

A friction stir and welding bead technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of increasing welding speed limit, large welding axial force, affecting welding efficiency, etc., to reduce welding difficulty and prolong Long service life, easy high-speed welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

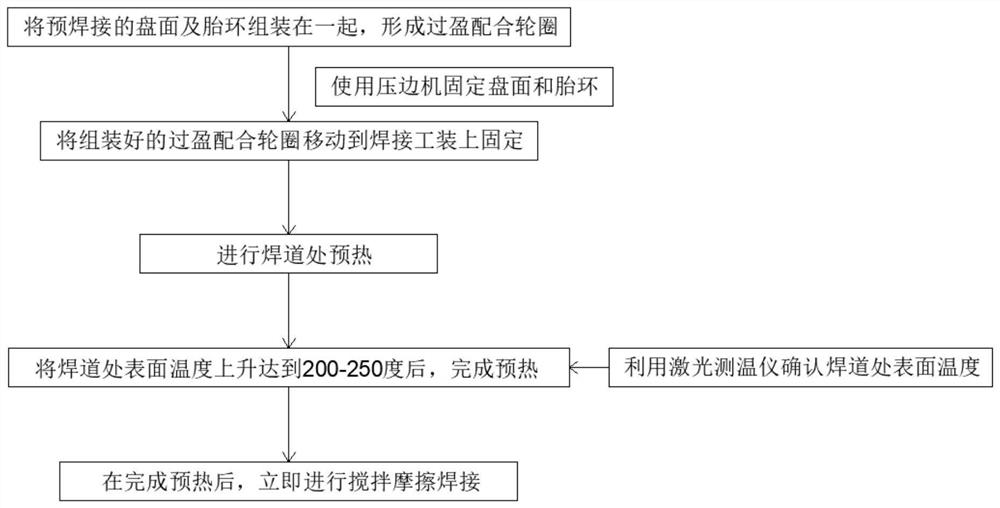

[0024] see figure 1 , the present invention provides a technical scheme: a preheating method for friction stir welding, comprising the following steps:

[0025] S1. Assemble the pre-welded disc surface and tire ring together to form an interference fit rim;

[0026] S2. Move the assembled interference fit rim to the welding tool to fix it, and use the edge holder to fix the disc surface and the tire ring;

[0027] S3. Preheat the weld bead;

[0028] S4. Use a laser thermometer to confirm the surface temperature of the weld bead. After reaching 200 degrees, complete the preheating;

[0029] S5. After preheating is completed, friction stir welding is performed immediately.

[0030] In this embodiment, preferably, before the disk surface and the tire ring are assembled together in S1, the disk surface and the tire ring are further cleaned to remove impurities and oil stains on the disk surface and the tire ring surface.

[0031] In this embodiment, preferably, the specific me...

Embodiment 2

[0048] see figure 1 , the present invention provides a technical scheme: a preheating method for friction stir welding, comprising the following steps:

[0049] S1. Assemble the pre-welded disc surface and tire ring together to form an interference fit rim;

[0050] S2. Move the assembled interference fit rim to the welding tool to fix it, and use the edge holder to fix the disc surface and the tire ring;

[0051] S3. Preheat the weld bead;

[0052] S4. Use a laser thermometer to confirm the surface temperature of the weld bead. After reaching 250 degrees, complete the preheating;

[0053] S5. After preheating is completed, friction stir welding is performed immediately.

[0054] In this embodiment, preferably, before the disk surface and the tire ring are assembled together in S1, the disk surface and the tire ring are further cleaned to remove impurities and oil stains on the disk surface and the tire ring surface.

[0055] In this embodiment, preferably, the specific me...

Embodiment 3

[0072] see figure 1 , the present invention provides a technical scheme: a preheating method for friction stir welding, comprising the following steps:

[0073] S1. Assemble the pre-welded disc surface and tire ring together to form an interference fit rim;

[0074] S2. Move the assembled interference fit rim to the welding tool to fix it, and use the edge holder to fix the disc surface and the tire ring;

[0075] S3. Preheat the weld bead;

[0076] S4. Use a laser thermometer to confirm the surface temperature of the weld bead. After reaching 220 degrees, complete the preheating;

[0077] S5. After preheating is completed, friction stir welding is performed immediately.

[0078] In this embodiment, preferably, before the disk surface and the tire ring are assembled together in S1, the disk surface and the tire ring are further cleaned to remove impurities and oil stains on the disk surface and the tire ring surface.

[0079] In this embodiment, preferably, the specific me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com