Steel structure component transfer device

A transfer device and steel structure technology, applied in the direction of transportation and packaging, loading/unloading, conveyor objects, etc., can solve problems such as difficult stacking, disorderly arrangement, and easy downward collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

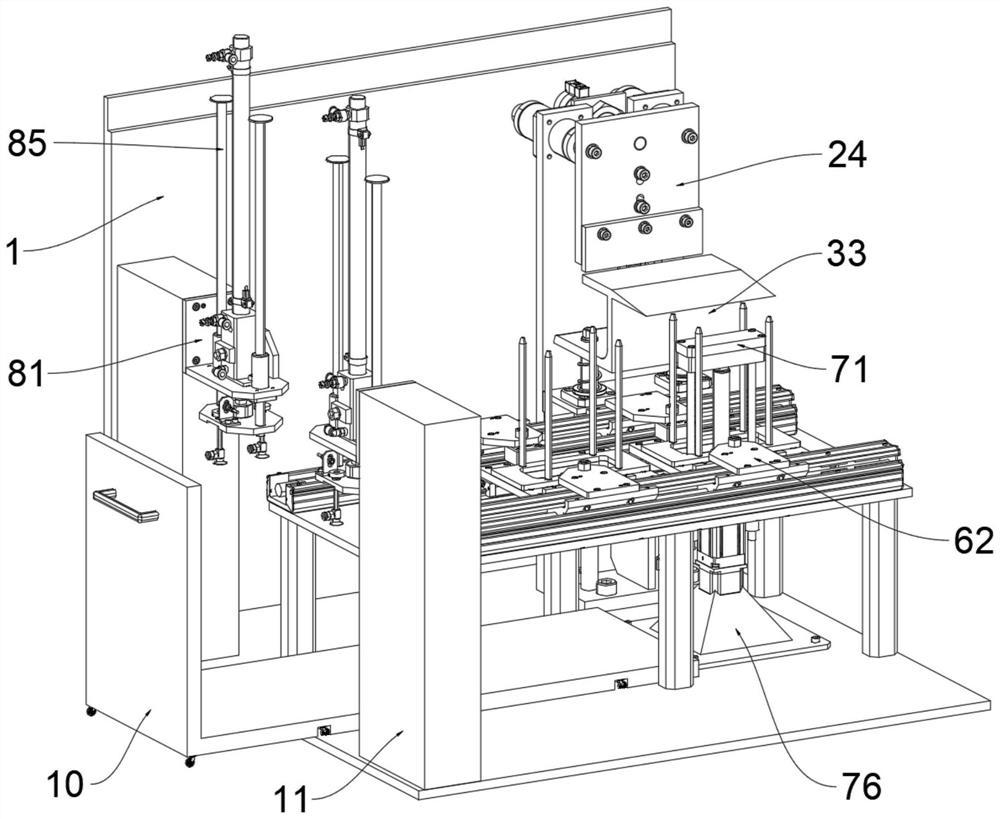

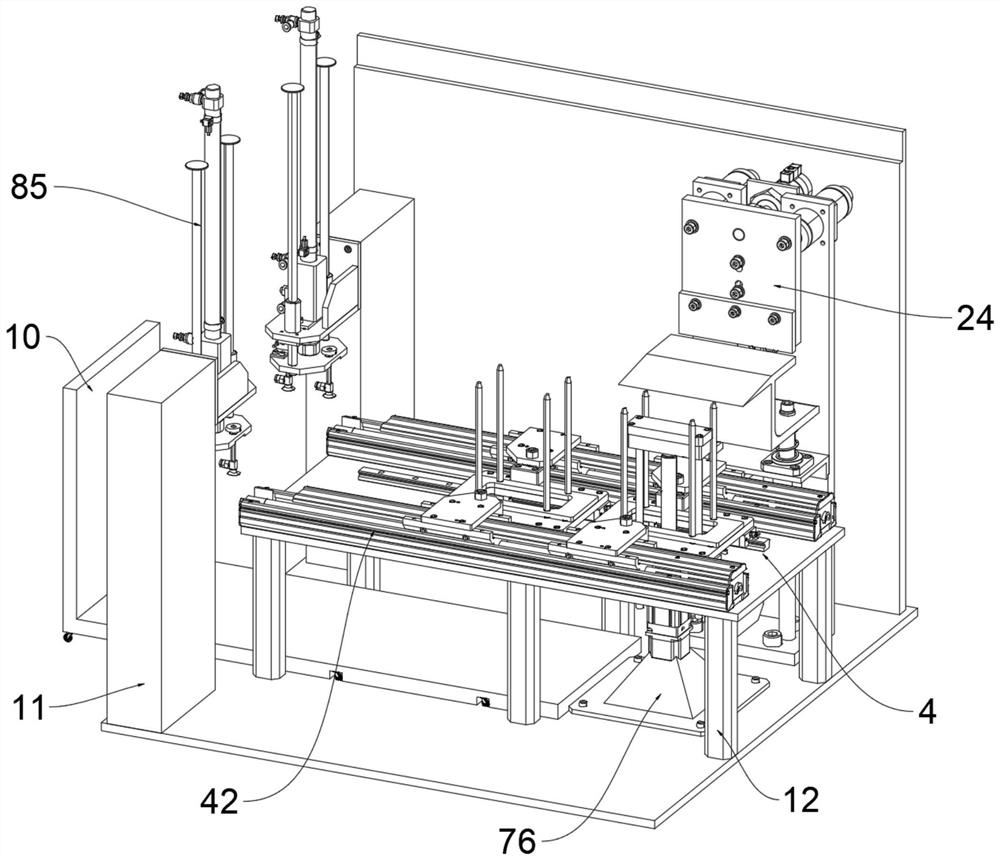

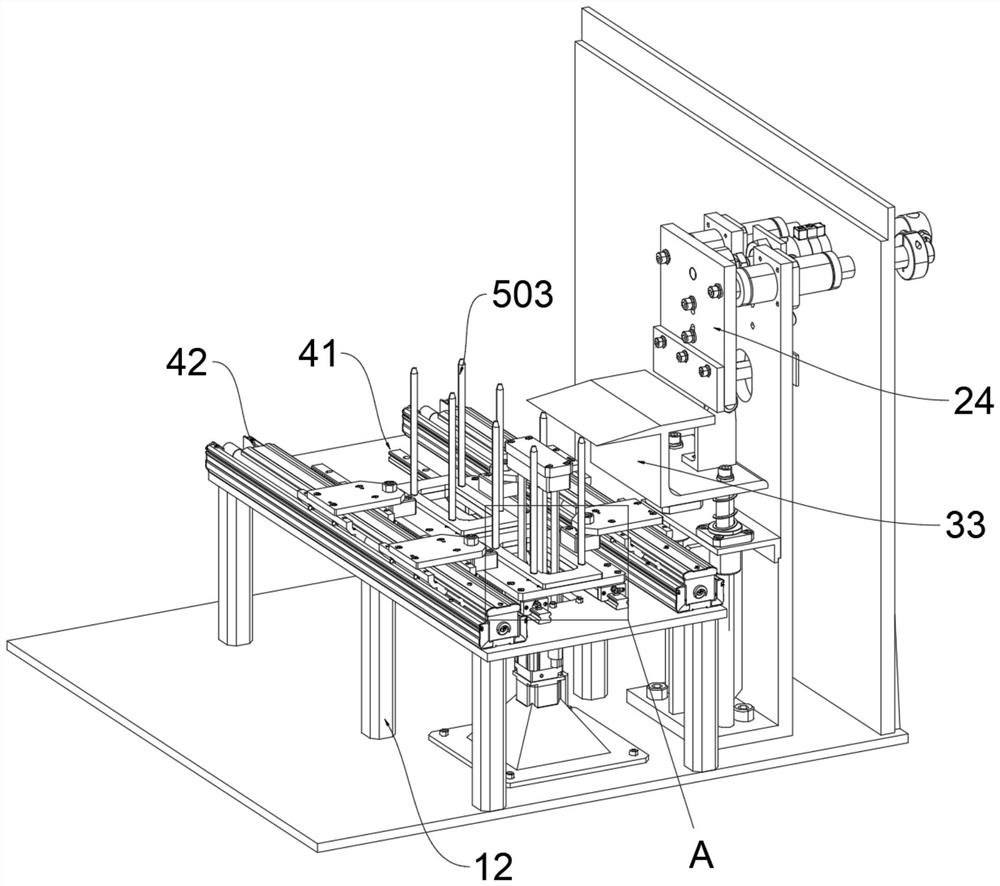

[0038] Please refer to Figure 1 to Figure 10 , this embodiment proposes a transfer device for steel structure components, including a main frame body 1, a bracket 5 and a sliding member 6; The left side of the top surface of the bottom plate of the main frame body 1 is fixed and vertically provided with two groups of uprights 11, the top surface of the bottom plate of the main frame body 1 is also provided with a support rod 12, and the top surface of the bottom plate of the main frame body 1 is also provided with a support rod 12. A supporting mechanism 7 is installed; a lifting device 8 is respectively installed on the right side of the opposite surfaces of the two groups of the uprights 11 ; an adsorption mechanism 9 is connected to the bottom of the lifting device 8 .

[0039] The top surface of the support rod 12 is connected with the transfer platform 4; the top surface of the transfer platform 4 is installed with a guide rail 41 and an electric slide rail 42;

[0040]...

Embodiment 2

[0052] On the basis of Example 1, the reverse flow setting operation can transfer the steel structural components on the transfer vehicle 10 to the next flow process line, that is, use the adsorption mechanism 9 to transfer the The steel structure components on the transfer vehicle 10 are lifted up to the transfer platform 4, so that the sliding member 6 is placed on the electric slide rail 42, and the bracket 5 is placed on the guide rail 41. The rail 42 and the sliding block 61 transfer the bracket 5 to the right side, and then use the supporting mechanism 7 to gradually lift the steel structure components on the bracket 5 upward. Use the push part 2 to push the steel structure components backward, pull the steel structure components back to the slope plate 3301, continue to push the steel structure components backward, and push them to the next assembly line to complete the transfer.

[0053] The specific usage and function of this embodiment: when the air pressure rod 22 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com