Rubber sealing ring production and collection device

A rubber sealing ring, collecting device technology, applied in transportation and packaging, conveyor objects, conveyors, etc., can solve problems such as unfavorable processing, high temperature, burns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

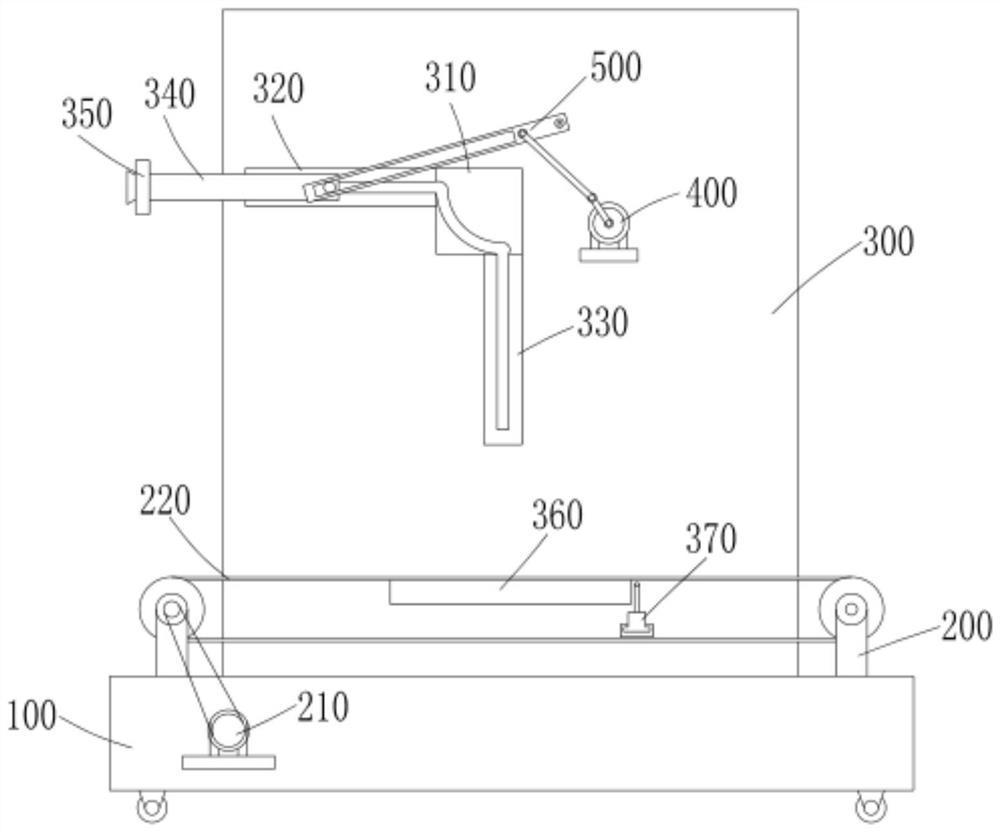

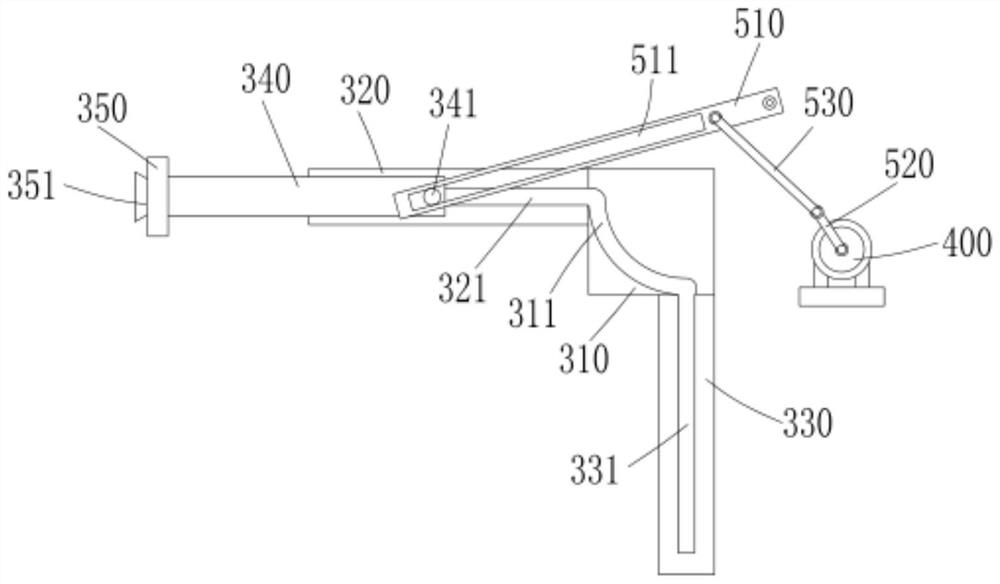

[0031] The present invention provides a technical solution: a rubber sealing ring production and collection device, comprising a base 100, a shelf plate 300, a movable plate 340 and a driving mechanism, a conveying mechanism 200 is installed on the base 100, and the conveying mechanism 200 includes a conveying belt group 220 and The first drive source 210 is used for intermittently driving the conveyor belt group 220 to operate; the shelf plate 300 is fixed on the rear side of the base 100, the front side of the shelf plate 300 is fixed with a support block, and the front end of the support block is provided with a fixed plate 310, a horizontal plate 320 is connected to the left side of the fixed plate 310, a horizontal slot 321 is arranged on the horizontal plate 320, a vertical plate 330 is connected to the lower side of the fixed plate 310, a vertical slot 331 is arranged on the vertical plate 330, and a vertical plate 331 is arranged on the fixed plate 310. Turning slot 311...

Embodiment 2

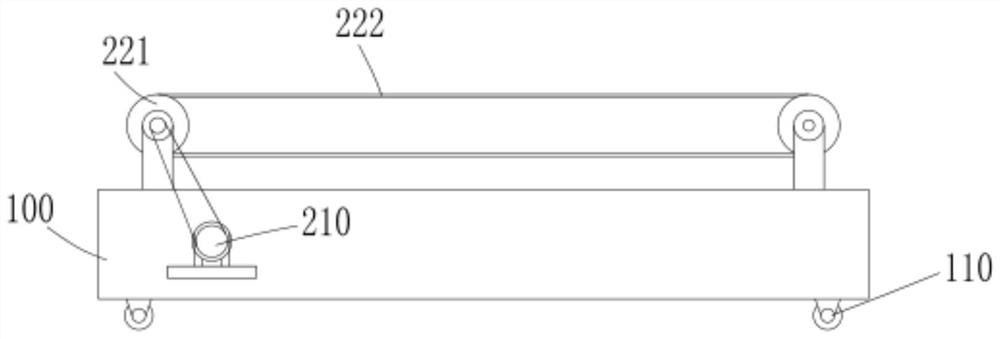

[0034] On the basis of Embodiment 1, the conveyor belt group 220 includes two sets of rotating rollers 221 and conveyor belts 222, and the conveyor belts 222 are sleeved on the two sets of rotating rollers 221; The components are several sets of collection grooves 2221 arranged on the conveyor belt 222, and the collection grooves 2221 correspond to the suction nozzles 351 one by one; the collection grooves 2221 are through grooves, and the front side of the shelf plate 300 is provided with a cooling plate 360, and the cooling plate 360 is forward It extends to the middle of the conveyor belt and contacts the upper side of the conveyor belt 222 for cooling the rubber sealing ring placed in the collecting tank 2221; the front side of the shelf plate 300 is fixed with a backing plate 370, and the upper side of the backing plate 370 is slidably connected to move The seat 371 and the upper end of the movable seat 371 are provided with several sets of sleeve rods 372, and the sleev...

Embodiment 3

[0037] On the basis of Embodiment 1 or Embodiment 2, the transmission assembly 500 includes a driving arm 510, a first rotating arm 520 and a second rotating arm 530. One end of the driving arm 510 is hinged with the frame plate 300, and a guide is provided on the driving arm 510. Slot 511, the clamping block 341 is slidably connected with the guide groove 511, one end of the first rotating arm 520 is rotatable with the output shaft of the second driving source 400, one end of the second rotating arm 530 is rotatably connected with the driving arm 510, the first rotating arm 520 and the second The rotating arm 530 is hinged.

[0038] Specifically, when the second driving source 400 rotates, the first rotating arm 520 and the second rotating arm 530 drive the driving arm 510 to move on the frame plate 300 , and the driving arm 510 is engaged with the clamping block 341 through the driving slot to drive the movement. The plate 340 reciprocates along the movable groove, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com