Multifunctional collating machine

A collating machine and multi-functional technology, applied in the field of multi-functional collating machines, can solve the problems of disjointness, paper wrinkle, increased pulling difficulty, etc., and achieve the effects of avoiding the use of compressors, reducing large resistance and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

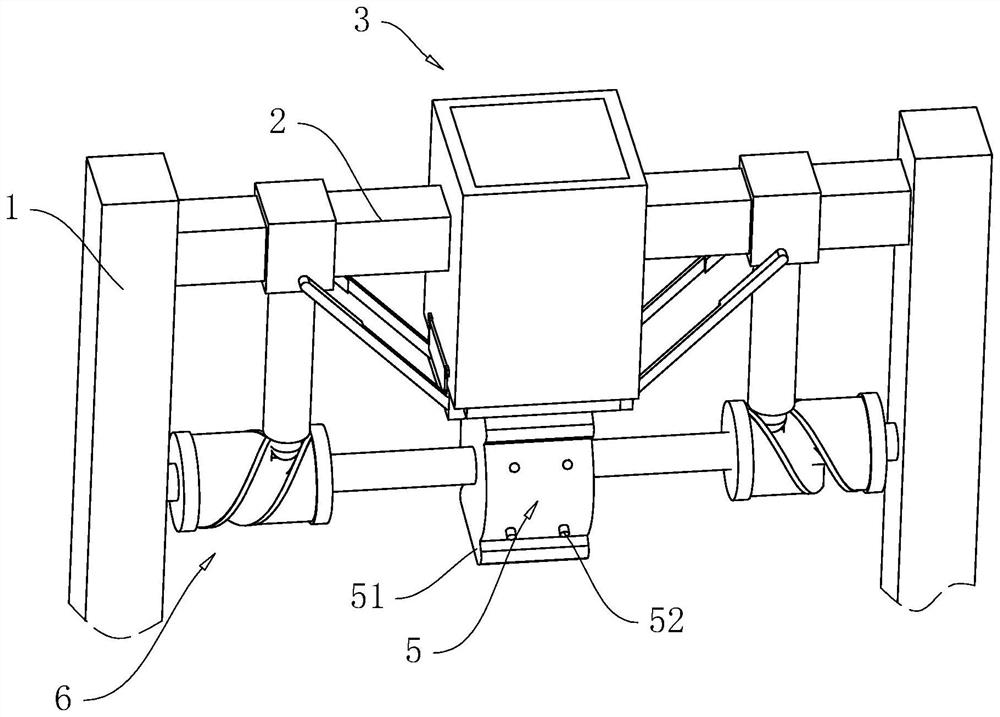

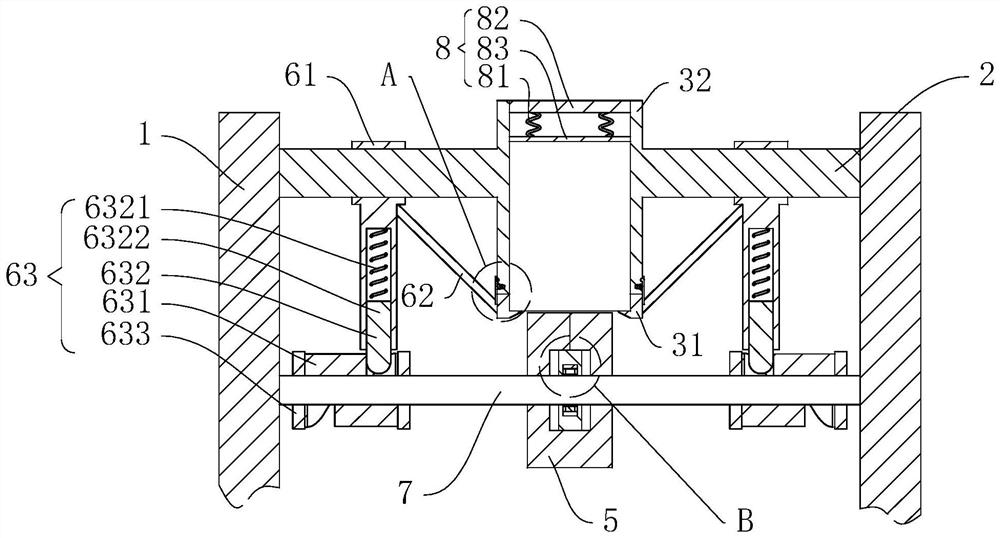

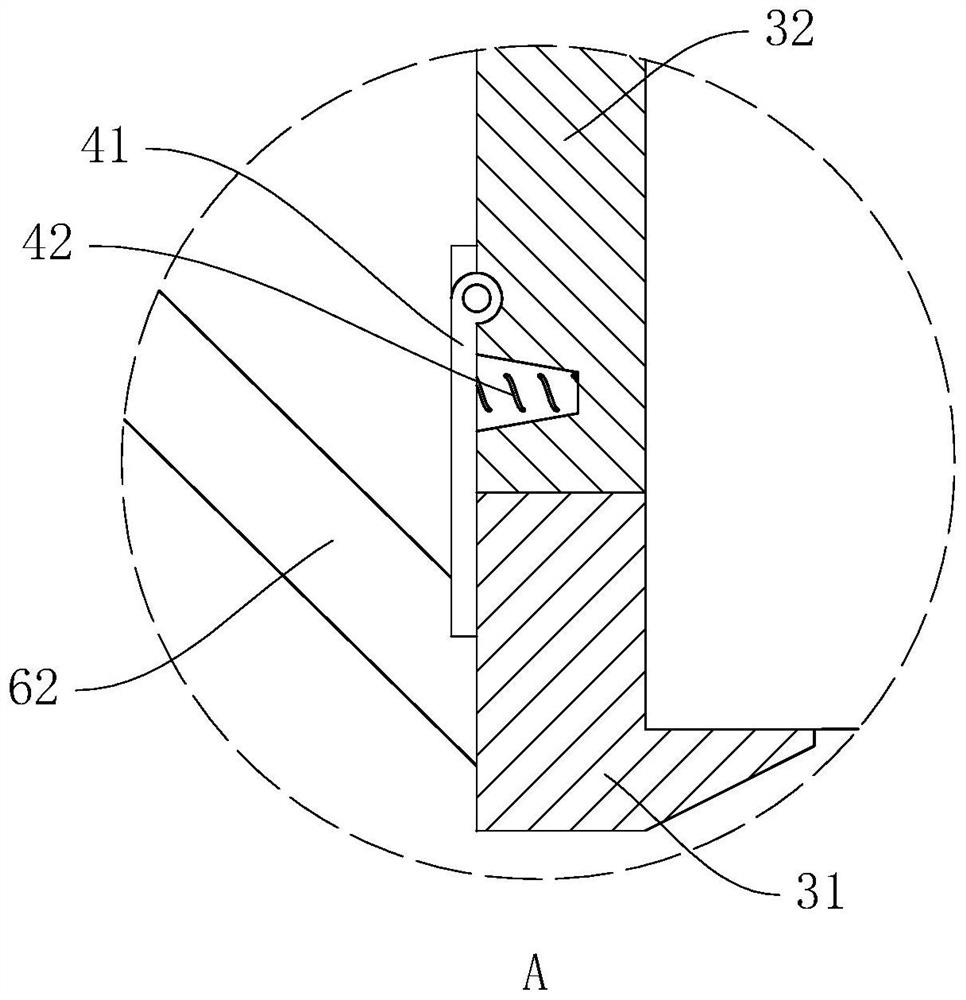

[0037] Attached to the following Figure 1-5 This application will be described in further detail.

[0038] The embodiment of the present application discloses a multifunctional collating machine, refer to figure 1 and figure 2 , a multifunctional collating machine includes a vertically arranged support frame 1, a fixed shaft 2 with a rectangular cross section is horizontally and fixedly arranged on the support frame 1, and a receiving structure 3 is arranged on the fixed shaft 2, and the receiving structure 3 It includes two L-shaped support sections 31 and a vertically arranged rectangular accommodating box 32. The accommodating box 32 is provided with a rectangular through hole along the vertical direction. The side of the long end is perpendicular to the axis of the fixed shaft 2, the short ends of the two supporting sections 31 are arranged opposite to each other, and the long ends of each supporting section 31 are hinged to the bottom of the accommodating box 32, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com