Catalytic waste gas treatment device for multi-bin waste gas treatment process

A waste gas treatment device and waste gas treatment technology, which is applied in the direction of combined device, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of affecting the efficiency of waste gas treatment and the deterioration of activated carbon adsorption effect, so as to reduce labor intensity , improve the utilization rate, improve the effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

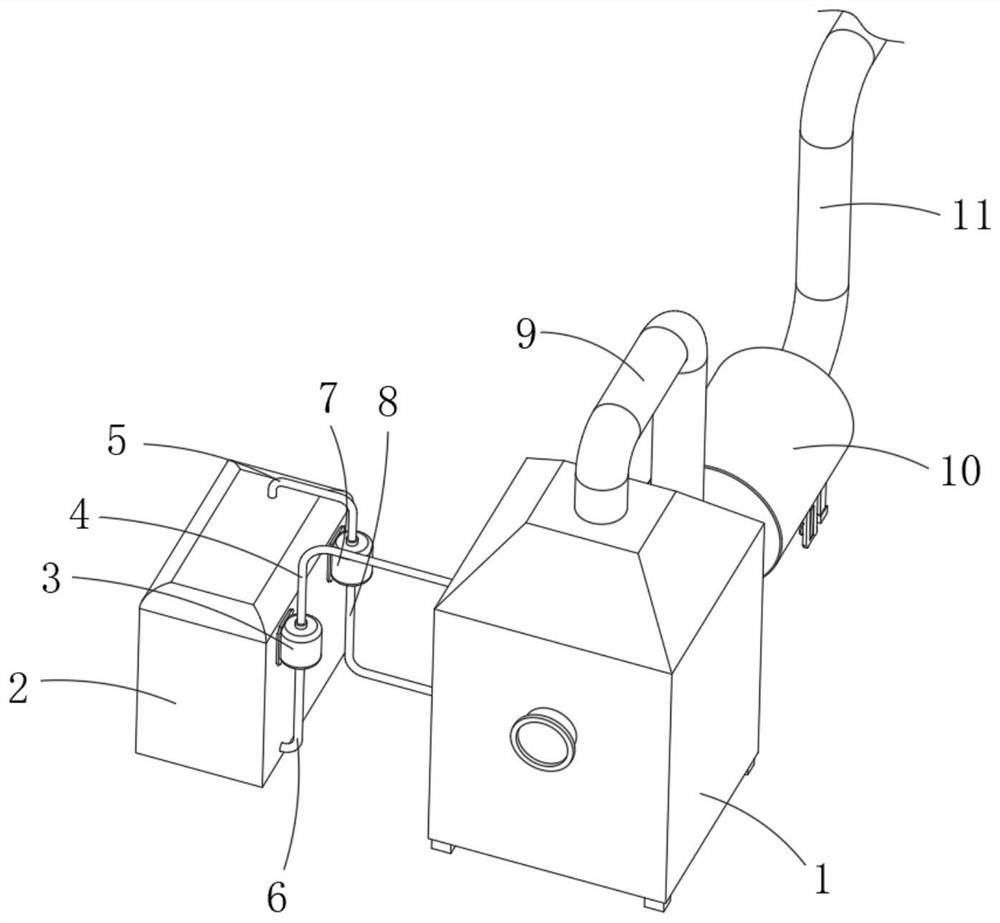

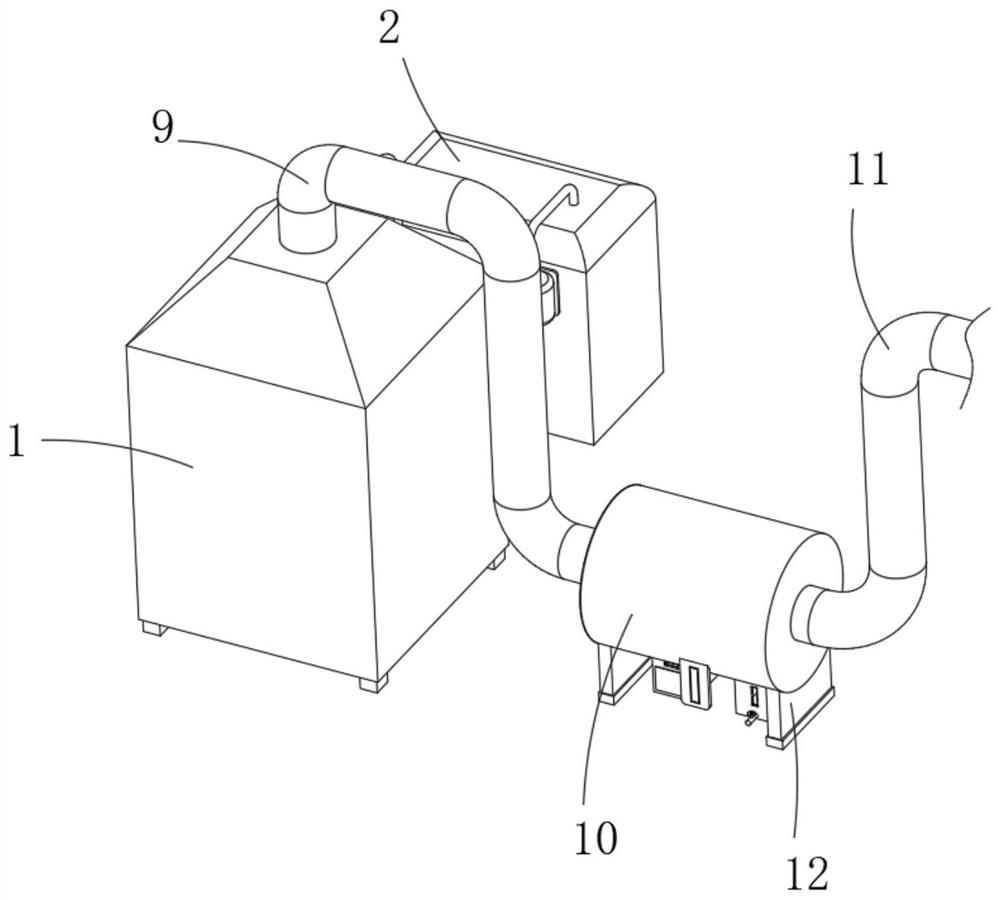

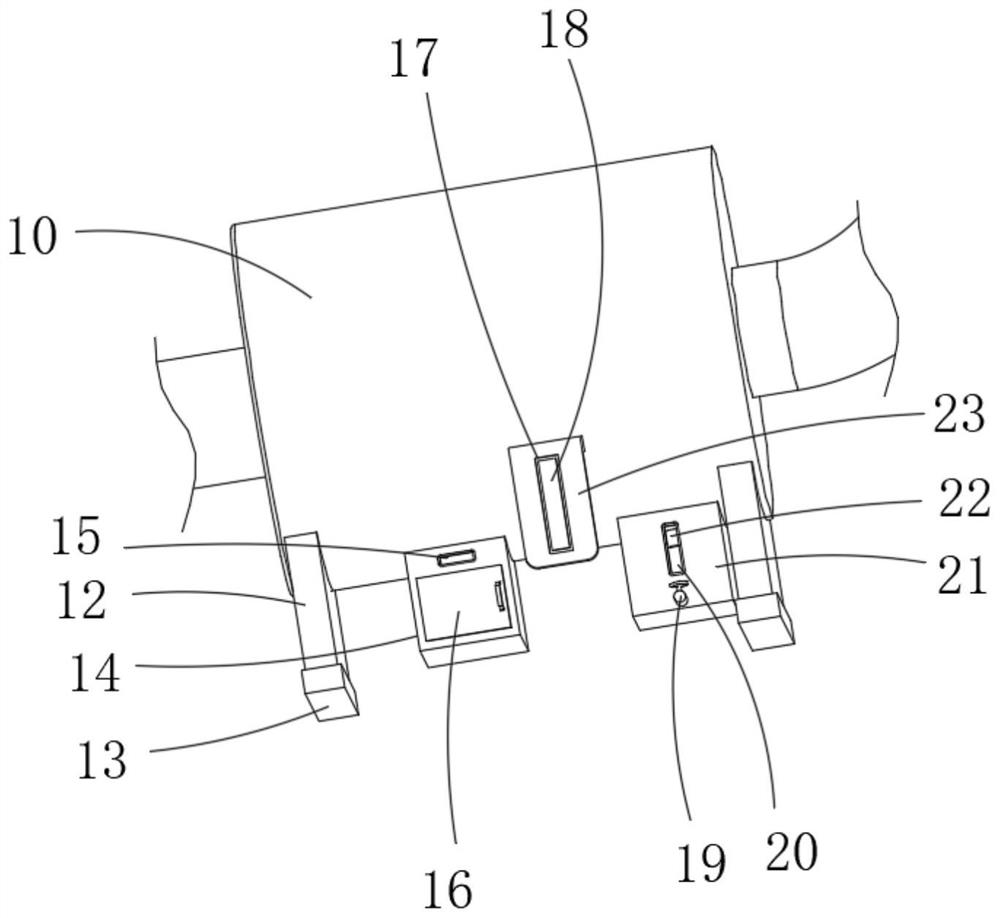

[0027] see Figures 1 to 5 , In the embodiment of the present invention, a multi-silo type waste gas treatment process catalytic waste gas treatment device includes a spray tower 1, a water circulation mechanism, a preliminary purification mechanism, a self-cleaning mechanism and a storage mechanism, and the spray tower 1 is connected with a water circulation mechanism Mechanism, the air outlet of the spray tower 1 is communicated with a preliminary purification mechanism, and the preliminary purification mechanism includes a purification cylinder 10, an air pipe 9, a support block 12, a dust filter 25 and a ceramic filter plate 27, a drainage pipe 22 and a ventilation pipe 11 O...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap