Continuous punch forming device for automobile sheet metal parts

A technology of stamping and forming of automobile sheet metal parts, which is applied in the field of automobile sheet metal processing, and can solve the problems of high friction of raw materials and difficult operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

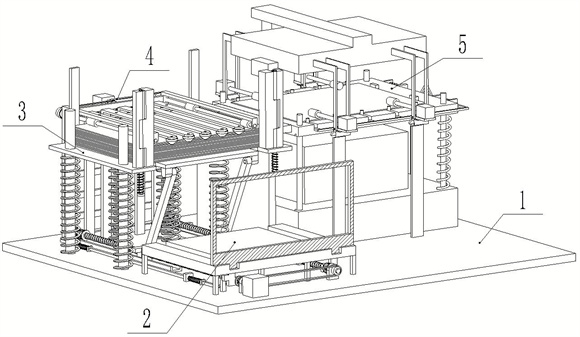

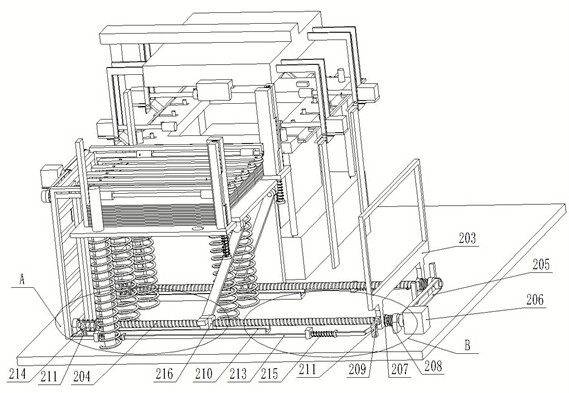

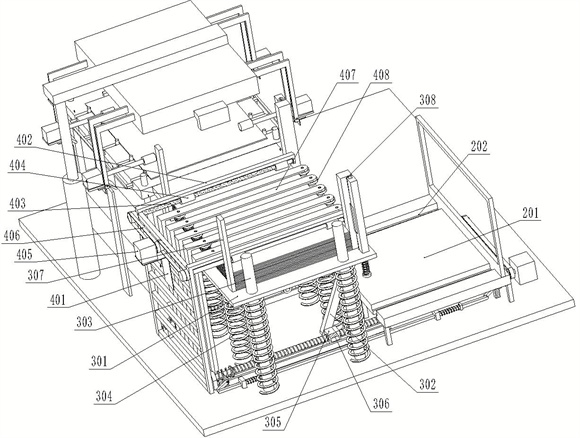

[0031] like Figure 1~Figure 12As shown, a continuous stamping and forming device for automobile sheet metal parts includes a base plate 1, a material storage table 2 is arranged on the base plate 1, a lifting table 3 is arranged on one side of the material storage table 2, and a conveying mechanism 4 is arranged on the lifting table 3 , a stamping table 5 is provided on one side of the lifting table 3; the material storage table 2 includes a table surface 201, and two No. Two lead screws 204 are provided below the table 201 at positions corresponding to the No. 1 slideway 202, the two lead screws 204 are connected by a No. 1 belt 205, and a No. 1 motor 206 is connected to one of the lead screws 204; the lead screw The two ends of 204 have no threads, and a slip ring 207 and a No. 1 spring 208 are symmetrically slidable at the places without threads. The lower end of the push frame 203 is sleeved on the lead screw 204, where there is no thread, the push frame 203 and the lead ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com