Rotary bottle blowing machine

A bottle blowing machine and bottle blowing cavity technology, which is applied to household appliances, hollow items, other household appliances, etc., can solve the problems of long time consumption, reduced production efficiency, cumbersome sterilization and disinfection steps, etc., and achieves convenient and simple operation and improves work efficiency. , to ensure the effect of moving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

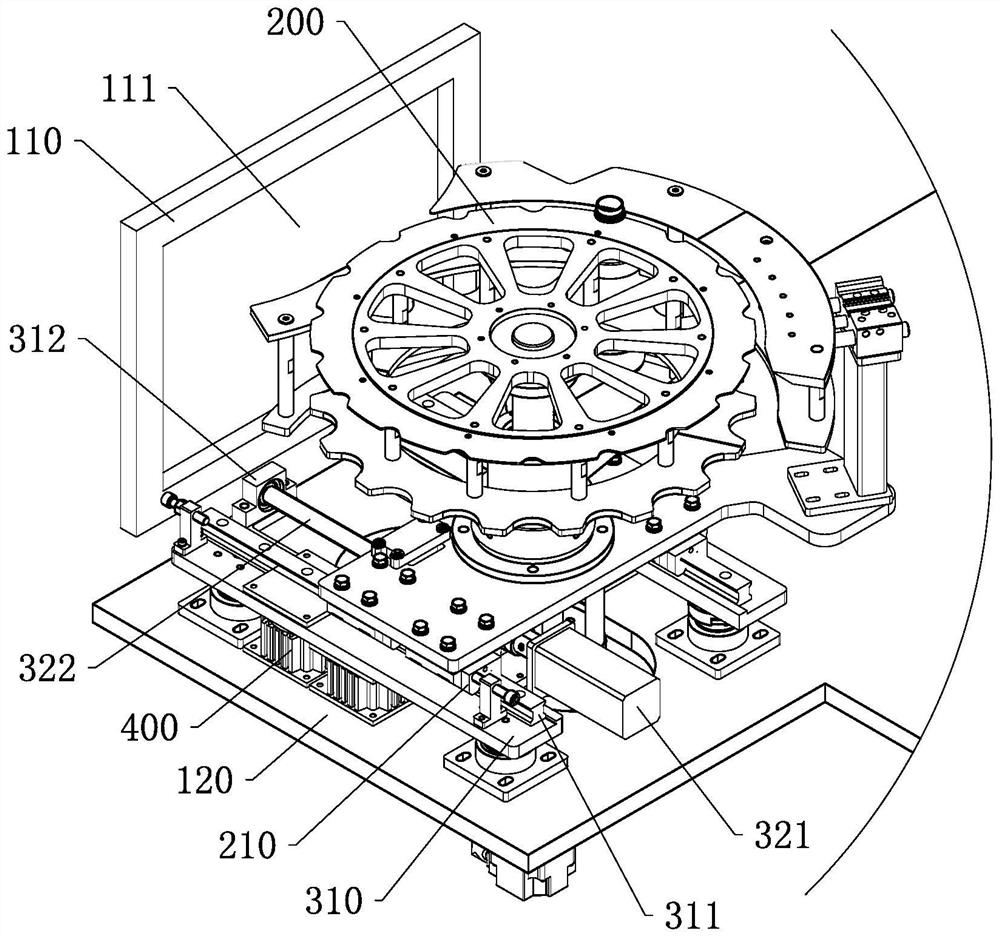

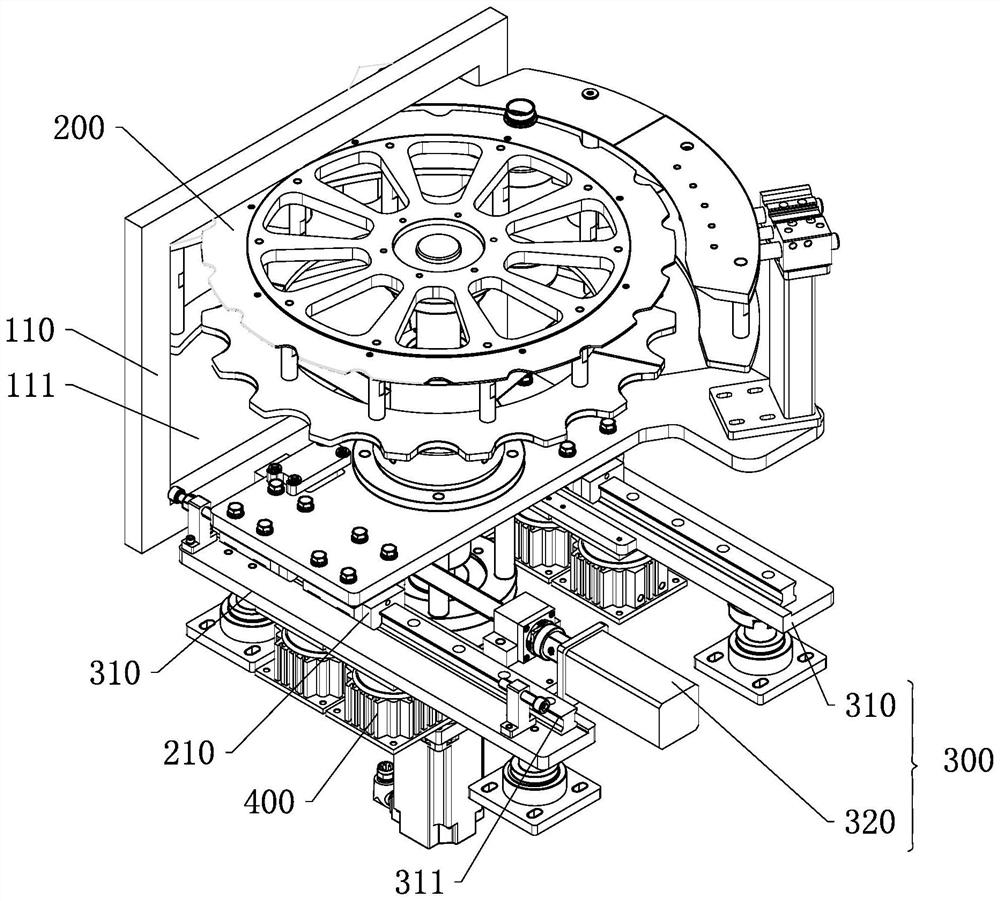

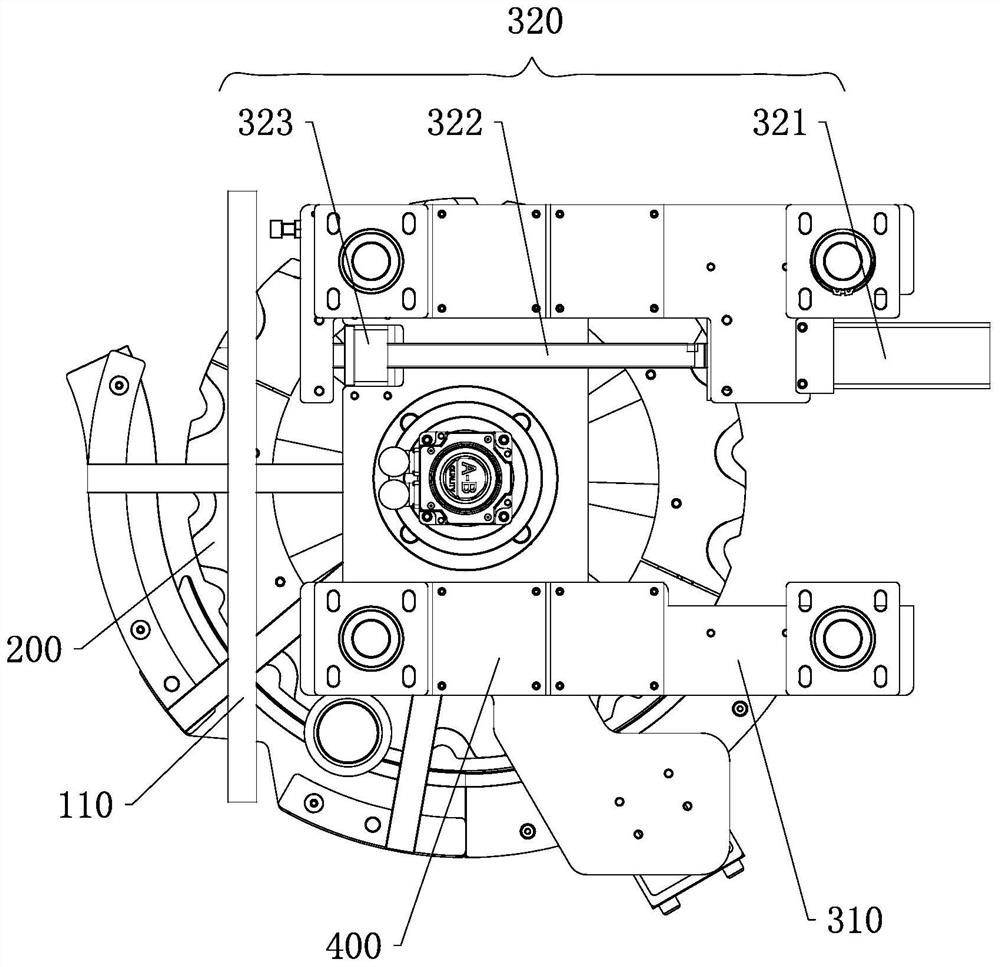

[0038] A rotary blow molding machine, such as Figure 1 to Figure 3 As shown, it includes a casing. A baffle 110 is vertically arranged in the casing. The baffle 110 divides the interior of the casing into a filling cavity and a blowing cavity arranged side by side. The blowing cavity is used to accommodate the blowing mechanism. The filling cavity is used to accommodate the filling mechanism, and the interior of the casing is separated by setting the baffle 110 to meet the different sterilization requirements of the filling cavity and the blowing cavity. A transition wheel 200 and a lifting and translation device for driving the transition wheel 200 to lift and translate are arranged in the blowing cavity. The transition wheel 200 is connected to the upper part of the lifting and translation device, and the baffle 110 is provided with a connection between the filling cavity and the blowing. The through hole 111 of the cavity, the transfer wheel 200 can pass through the through ...

Embodiment 2

[0046] The difference between this embodiment and the first embodiment is that, in this embodiment, the linear driving mechanism is a driving cylinder, the driving cylinder is fixed on the mounting seat, and the output shaft of the driving cylinder is horizontally arranged and connected to the bottom of the transition wheel disc, It is used to push the transition wheel to translate, and the output force of the cylinder is larger, and as a linear drive mechanism, the driving effect of the heavy transition wheel is better. Of course, it can be understood that the linear drive mechanism in this embodiment can also be an electric push rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com