Rope winding mechanism of novel soft rope knotter

A knotter and soft rope technology, which is applied in the field of knotting machines, can solve the problems of easy falling off of the cord, high knotting success rate, and easy fixing of the cord, etc., to improve the knotting success rate, reduce vibration, and reduce gaps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

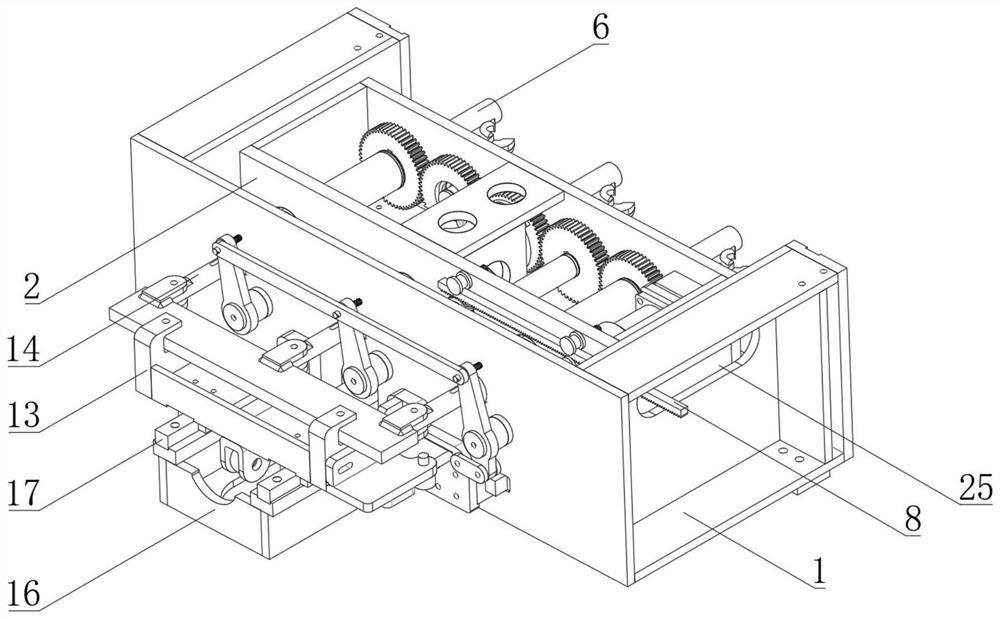

[0033] see Figure 1-9 , a new type of rope winding mechanism for a soft rope knotter, comprising a casing 1, the inner wall of the casing 1 is connected with a sliding frame 2 through a track, a rotating drum 3 is installed inside the sliding frame 2, and the outer surface of the rotating drum 3 is provided with a spiral Slot 4, a drive gear 5 is detachably connected to one side of the drum 3, a drive mechanism is provided on the back of the sliding frame 2, a support drum 6 is fixedly connected to the back of the shell 1, a pulling mechanism is installed at the bottom of the shell 1, and the drum 3 A fixing mechanism is provided near one end of the driving gear 5 .

[0034] In this embodiment, the sliding frame 2 can slide in the casing 1. After the fixing mechanism clamps the wire rope, the rotation of the rotating drum 3 will drive the fixing mechanism at one end of the rotating drum 3 to rotate, thereby winding the wire rope on the fixing mechanism. The rope operation, a...

Embodiment 2

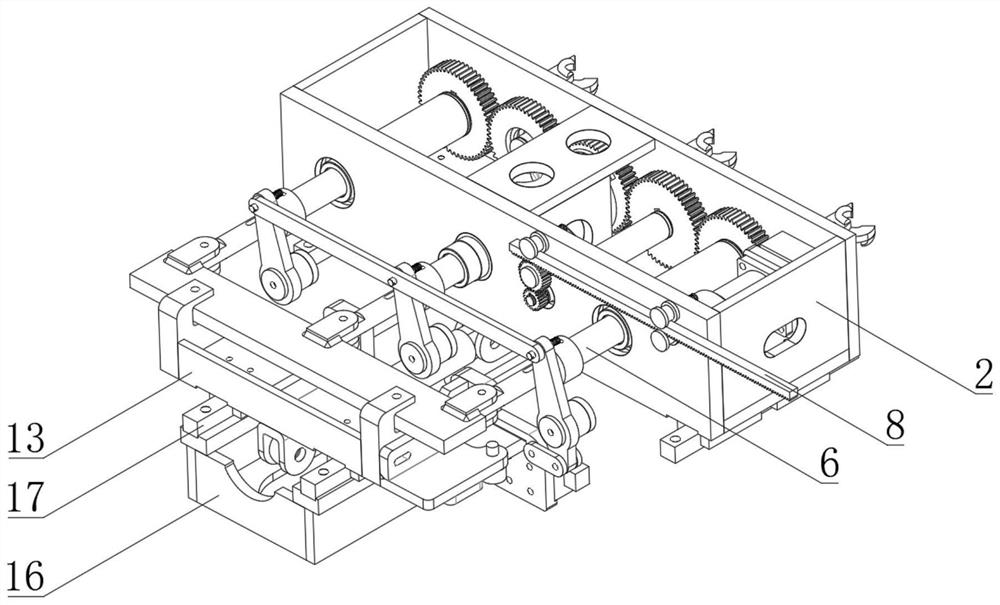

[0036] According to Embodiment 1, the driving mechanism includes a guide wheel 7 mounted on the back of the sliding frame 2, the inner wall of the guiding wheel 7 is provided with a rack 8, one side of the back of the sliding frame 2 is provided with a connecting wheel 9, and one side of the driving gear 5 is engaged with There is a reversing gear 10, and the inner wall of the reversing gear 10 is connected with a connecting rod 11 through a keyway.

[0037] In this embodiment, the guide wheel 7 pushes the rack 8 against the connecting wheel 9 to ensure that the rack 8 and the connecting wheel 9 fit together, and a reversing gear 10 is arranged between the two driving gears 5 to ensure that each driving The rotation direction between the gears 5 is the same, which is more neat in the process of knotting.

Embodiment 3

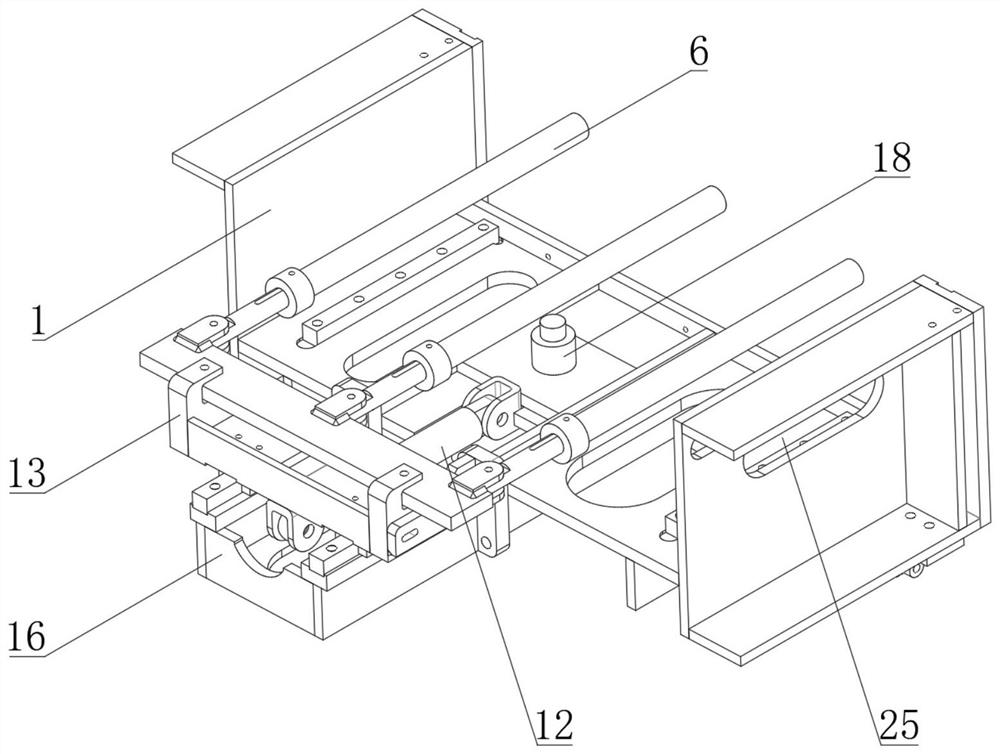

[0039] According to Embodiment 2, both the lower surface of the rack 8 and the end of the connecting rod 11 away from the reversing gear 10 are engaged with the outer surface of the connecting wheel 9 .

[0040] In this embodiment, when the connecting rod 11 rotates, the connecting rod 11 will drive the connecting wheel 9 to rotate together, thereby driving the rack 8 to move left and right. The position of the connecting rod 11 is positioned to determine the rotation angle of the connecting rod 11, and the rotation is driven by the hydraulic motor on the side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com