Spring type width adjusting mechanism, bagging assembly and integrated large-width bag feeding packaging machine

A spring-type, width-adjusting technology, applied in the directions of transportation and packaging, packaging, transportation packaging, etc., can solve the problem of inappropriate large-width packaging bags, and achieve the effect of neat sealing and ensuring sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

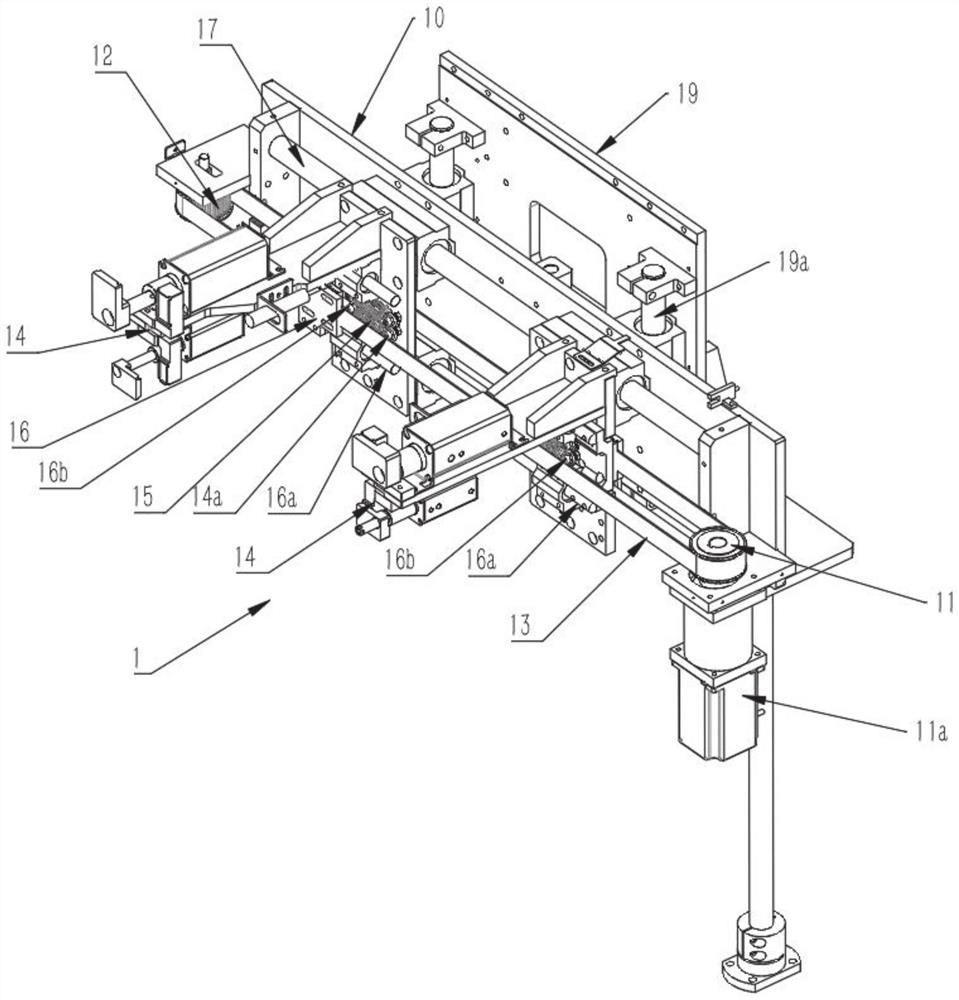

[0056] A spring-type width adjustment mechanism can ensure neat sealing without breaking the packaging bag, such as Figure 1-Figure 15 As shown, it is specially set to the following structure:

[0057] The spring type width adjustment mechanism includes a width adjustment mechanism mounting plate 10 , a driving pulley 11 , a passive pulley 12 , a belt 13 , a clamping device 14 , a tension spring 15 , and a belt connecting plate 16 .

[0058] like Figure 1-4 shown.

[0059] The driving pulley 11 and the passive pulley 12 are arranged in sequence in the lateral direction, and their rotating shafts are parallel and vertical. 10 on the front. The driving pulley 11 is connected with a driving device, and the driving device is a width adjusting motor 11 a whose main shaft is inserted into the shaft hole of the driving pulley 11 . The belt surface of the belt 13 is arranged vertically, and the belt 13 is arranged horizontally as a whole and is connected to the driving pulley 11...

Embodiment 2

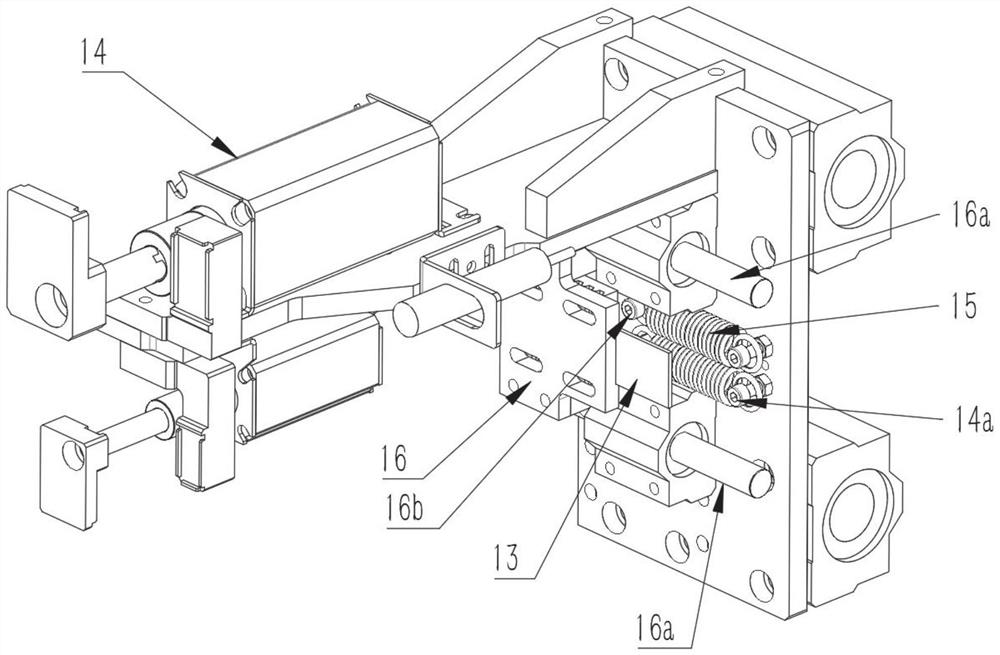

[0067] The present embodiment is further optimized on the basis of the above-mentioned embodiment, and further, in order to better realize the present invention, the following setting structure is specially adopted:

[0068] In this embodiment, in the belt connecting plate 16 and the clamping device 14 connected in the spring-type width adjustment mechanism, the distance between the first fixing bolt 14a and the second fixing bolt 16b in the lateral direction is greater than the natural length of the tension spring 15, The tension spring 15 is always in a stretched state.

[0069] In this embodiment, the tension spring 15 is always in a tension state, so that the belt connecting plate 16 and the clamping device 14 always maintain an opposite pulling force, which can ensure that the clamping device 14 does not generate free movement after the belt connecting plate 16 fixes the belt 13 .

Embodiment 3

[0071] The present embodiment is further optimized on the basis of any of the above-mentioned embodiments, and further, in order to better realize the present invention, the following setting structure is particularly adopted:

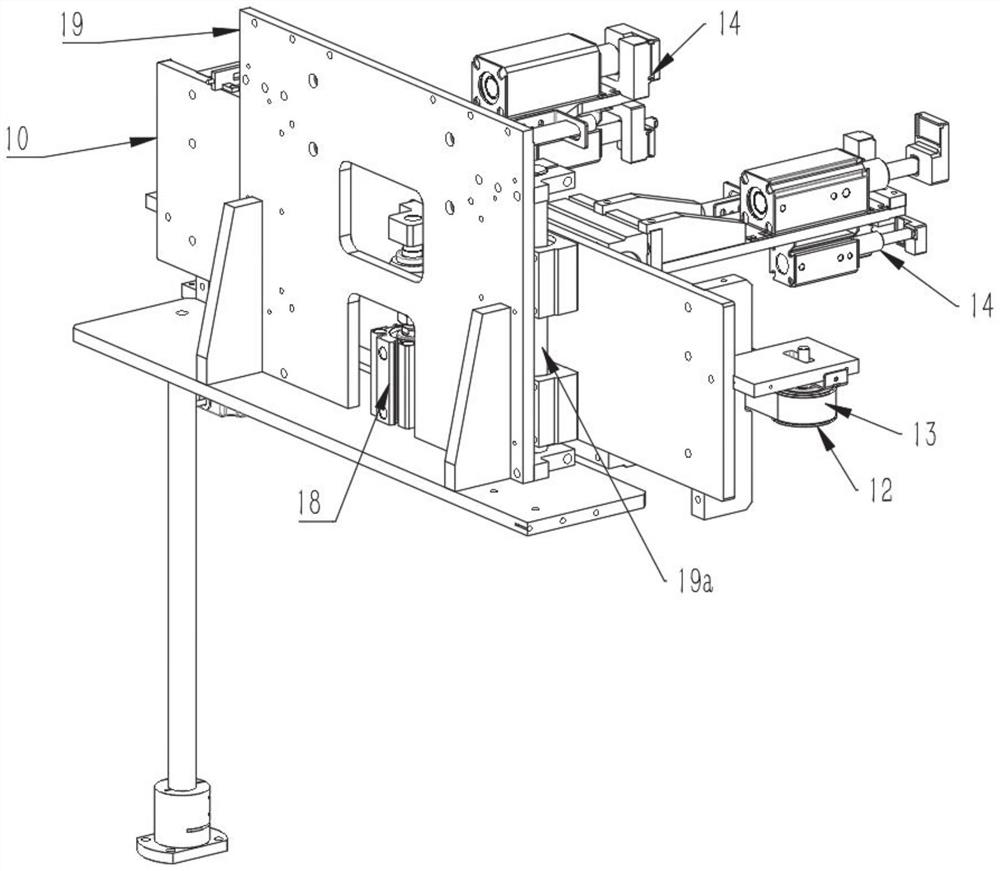

[0072] In this embodiment, the spring-type width adjustment mechanism further includes a jacking device 18 and a support plate 19 .

[0073] Two linear bearings arranged in sequence in the lateral direction are fixedly connected to the back of the mounting plate 10 of the width adjustment mechanism. The front surface of the support plate 19 is fixedly connected with two vertically arranged upper and lower guide rails 19a arranged in sequence in the lateral direction. The back of the mounting plate 10 of the width adjustment mechanism is movably connected with the corresponding upper and lower guide rails 19a through linear bearings.

[0074]The jacking device 18 is a vertically arranged air cylinder. The jacking device 18 can drive the jacking device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com