Electronic trigger type safety tongs

A safety gear and trigger-type technology, which is applied in the field of safety protection braking devices, can solve the problems of slow overall response, increased overall space size, and increased braking capacity of safety protection braking devices, achieving small size, simple structure, Effects with high trigger reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

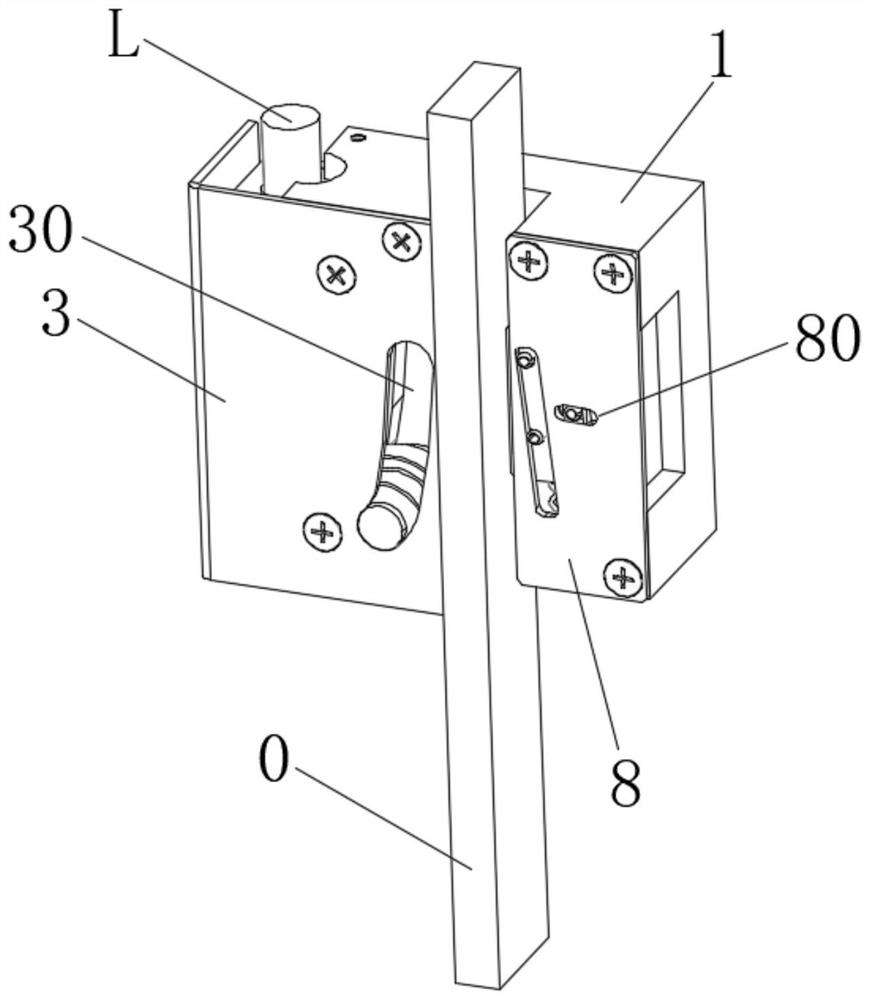

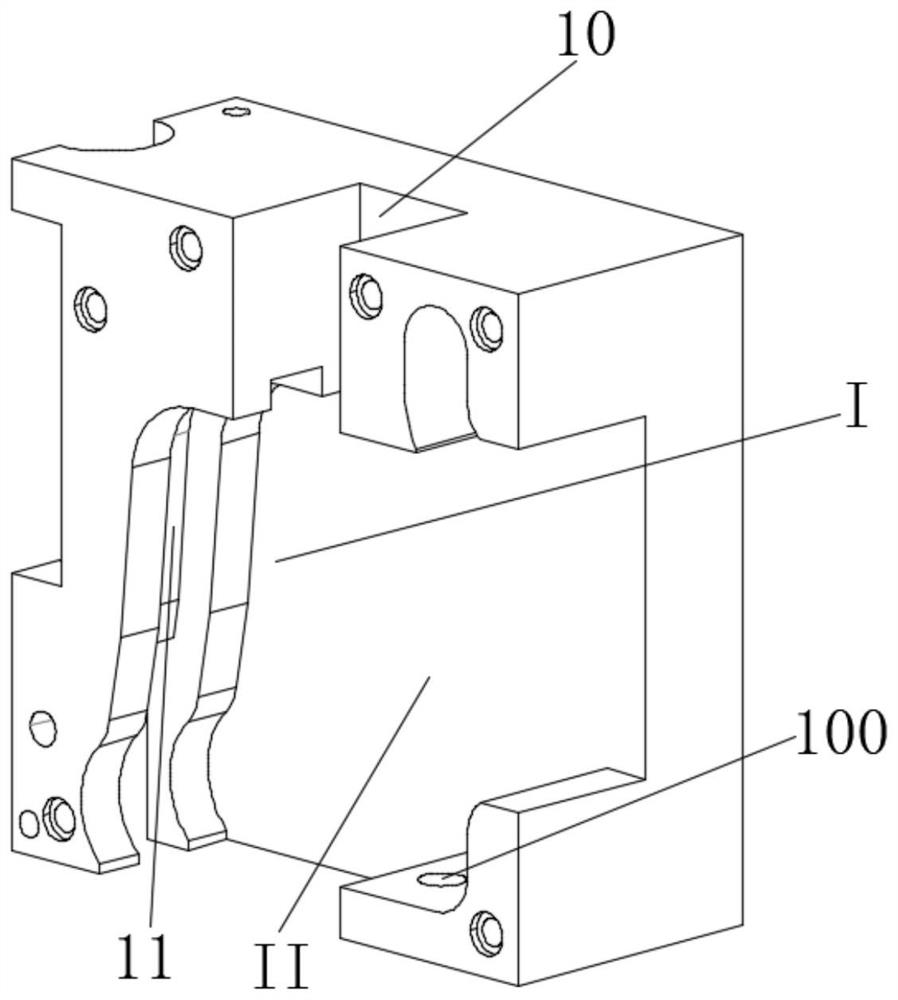

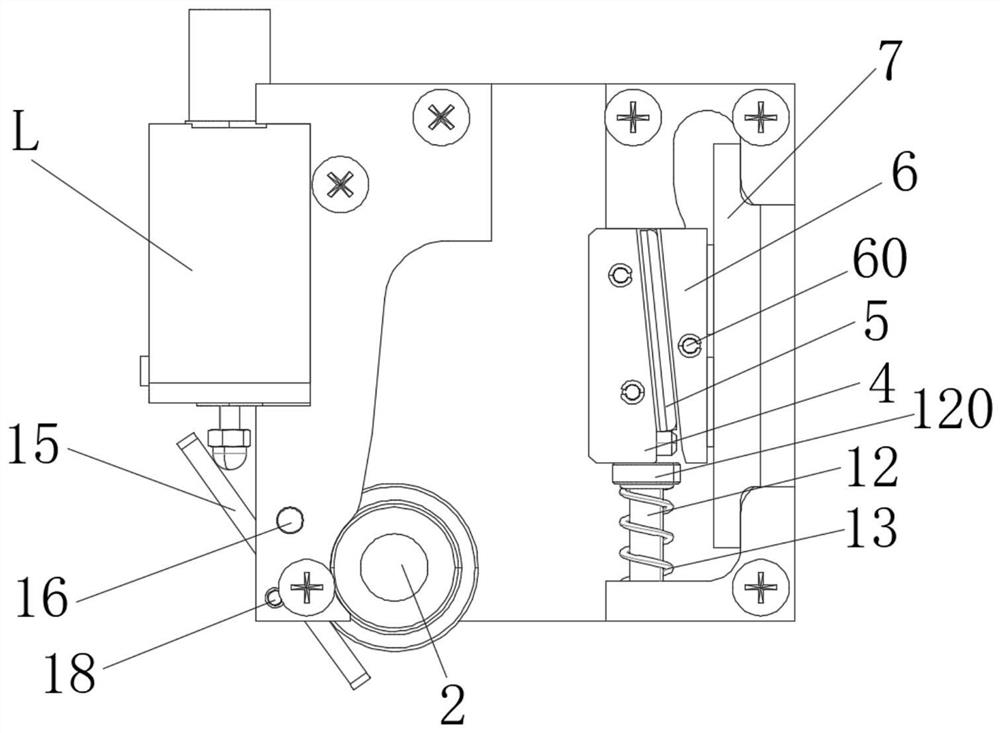

[0035] like Figure 1 to Figure 4 As shown, the electronic trigger safety gear of this embodiment includes a caliper body 1, a braking roller 2, a guide cover 3, a fixed wedge 4, a ball cage 5, a sliding seat 6, a bar-shaped leaf spring 7, a right Cover plate 8, electronic trigger L and lever mechanism.

[0036] Specifically, the caliper body 1 has a vertically extending guide rail channel 10, the caliper body 1 is located on the left and right sides of the guide rail channel 10 to form a first recess I and a second recess portion II, and the first recess portion I is used for installing the brake rollers 2. The second recess II is used to install the fixed wedge 4, the ball cage 5, the sliding seat 6 and the strip spring 7, so that the brake roller 2 and the fixed wedge 4 are located on the left and right sides of the guide rail channel 10, respectively. side, so as to cooperate with the elevator guide rail 0.

[0037] Wherein, the front side of the first concave portion 1 ...

Embodiment 2

[0050] The difference between the electronic trigger safety gear of this embodiment and Embodiment 1 is:

[0051] like Figure 5 As shown, the electronic trigger L of this embodiment can also be installed on the bottom of the left side wall of the caliper body, installed obliquely, and directly use the driving end of the electromagnet to vertically drive the brake roller to move upwards to connect with the elevator guide rail. It can also realize the trigger braking of the safety gear to meet the needs of different applications;

[0052] For other structures, refer to Embodiment 1.

Embodiment 3

[0054] The difference between the electronic trigger safety gear of this embodiment and Embodiment 1 is:

[0055] like Image 6 As shown, the electronic trigger L of this embodiment can also be installed at the bottom of the left side wall of the clamp body, and the electromagnet horizontally drives the linkage frame K to drive the braking roller 2 to move upward, and contacts the elevator guide rail to achieve The horizontal drive can also realize the trigger braking of the safety gear to meet the needs of different applications;

[0056] For other structures, refer to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com