Water channel sludge scraping device for water conservancy project

A scraping device and water conservancy engineering technology, applied in water supply devices, waterway systems, cleaning of sewer pipes, etc., can solve problems such as low efficiency, easy to affect sludge scraping, inability to thoroughly clean water channels, etc., to facilitate unlocking the scraper, automatic fixing Unlock the effect of the scraper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

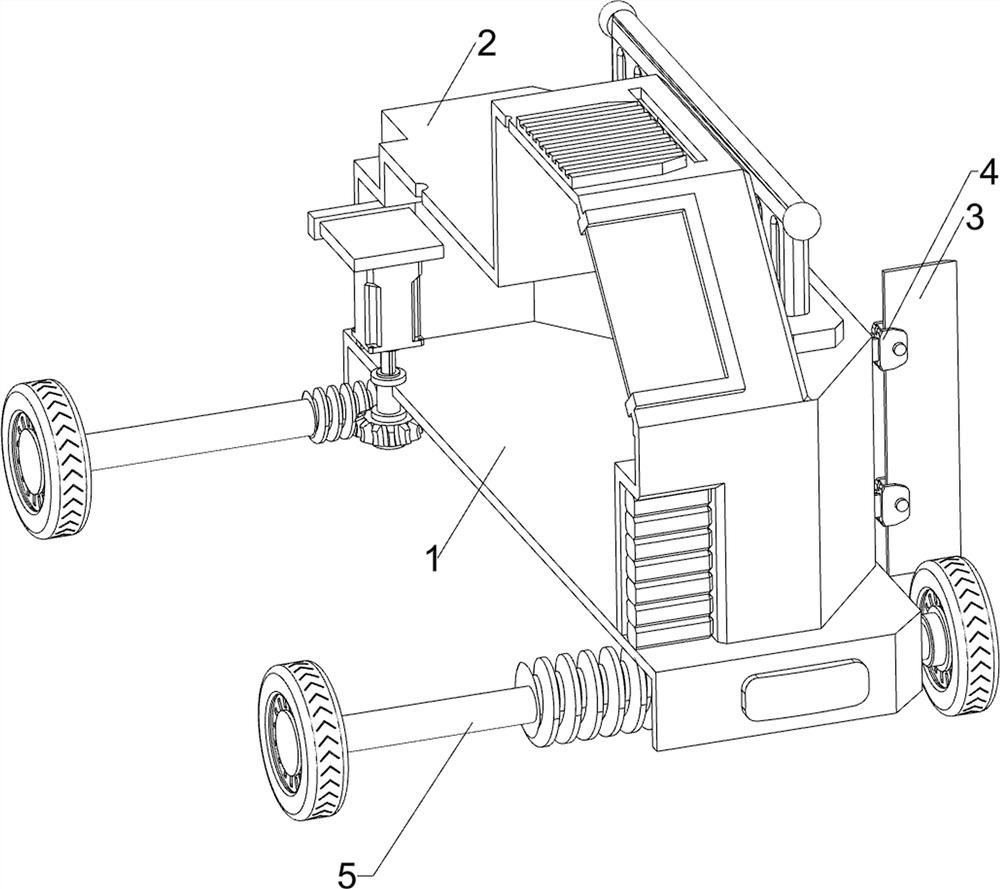

[0034] like Figure 1 to Figure 6 As shown in the figure, the present embodiment discloses a device for scraping sludge in water conservancy projects, including a base 1, a casing 2, a scraper 3, a scraping assembly 4 and a walking assembly 5. The upper part of the base 1 is connected with a casing 2, and the front side of the casing 2 A scraping assembly 4 is provided, and scrapers 3 are provided on the left and right sides of the scraping assembly 4 , and a walking assembly 5 is provided between the front and rear sides of the base 1 and the inner rear side of the housing 2 .

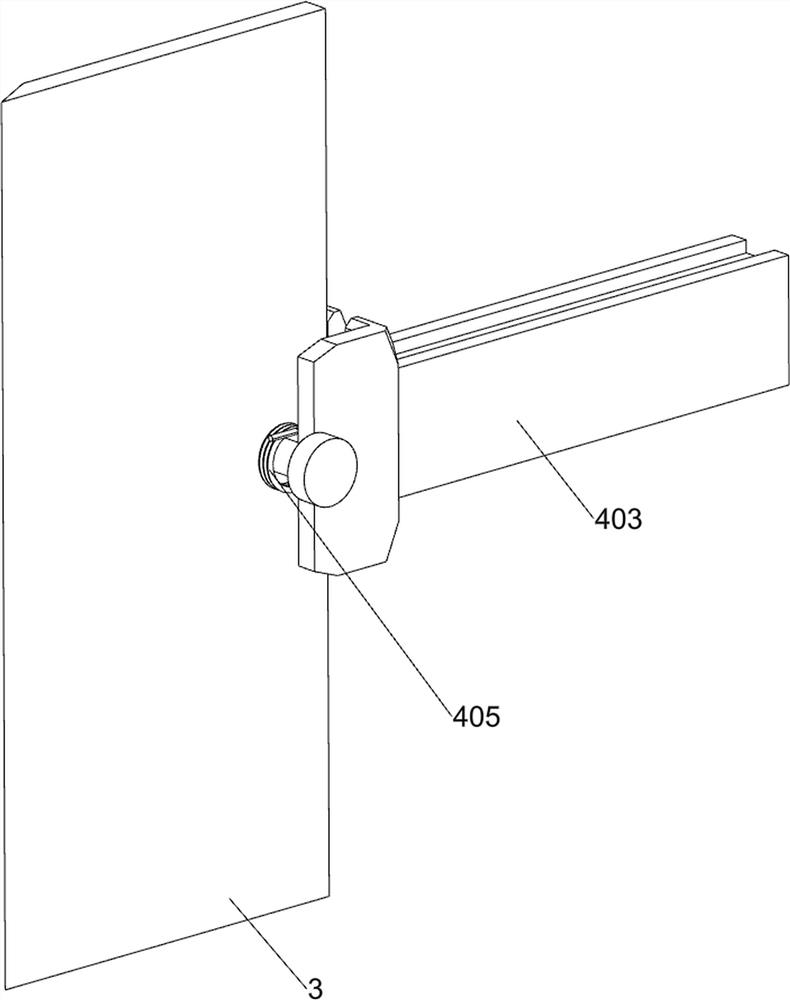

[0035] The scraping assembly 4 includes a first support frame 401, a first sliding sleeve 402, a first sliding rod 403, a first spring 404 and a torsion spring 405. The front and left sides of the inner casing 2 are symmetrically connected with the first support frame. 401, a first sliding sleeve 402 is symmetrically connected up and down between the first support frames 401 on the left and right side...

Embodiment 2

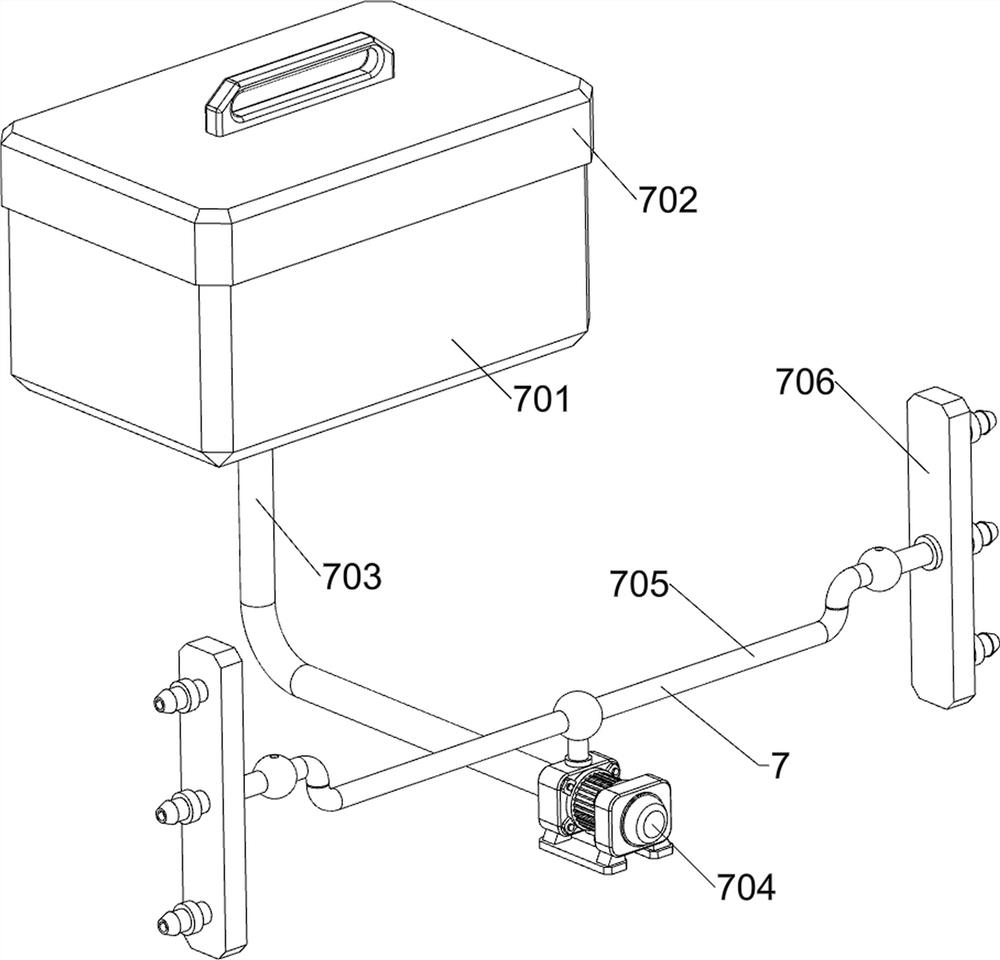

[0039] like figure 1 , figure 2 , Figure 7 to Figure 15 As shown, in some embodiments, it also includes a moving assembly 6, and the moving assembly 6 includes a second support frame 601, a first guide rod 602, a sliding frame 603, a second spring 604, a push-pull rod 605, and a second guide rod 606, the slide plate 607, the third spring 608 and the connecting rod 609, a second support frame 601 is connected to the front side of the upper part of the base 1, a first guide rod 602 is connected to the upper part of the second support frame 601, and the first guide rod 602 is slidably connected There is a sliding frame 603. A second spring 604 is connected between the sliding frame 603 and the guide rod. The second spring 604 is sleeved on the first guide rod 602. The upper rear side of the sliding frame 603 is symmetrically connected with a push-pull rod 605. The push-pull rod 605 The upper part is slidably connected to the housing 2 , the inner side of the first support fra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap