Scroll compressor

A scroll compressor and compression mechanism technology, applied in the field of scroll compressors, can solve the problems of complexity, difficult structural design, and the compressor does not have a radially flexible structure and an axially flexible structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following descriptions of various embodiments of the present invention are exemplary only, and in no way limit the invention and its application or usage. The same reference numerals are used to denote the same components in the various drawings, and thus the configuration of the same components will not be described repeatedly.

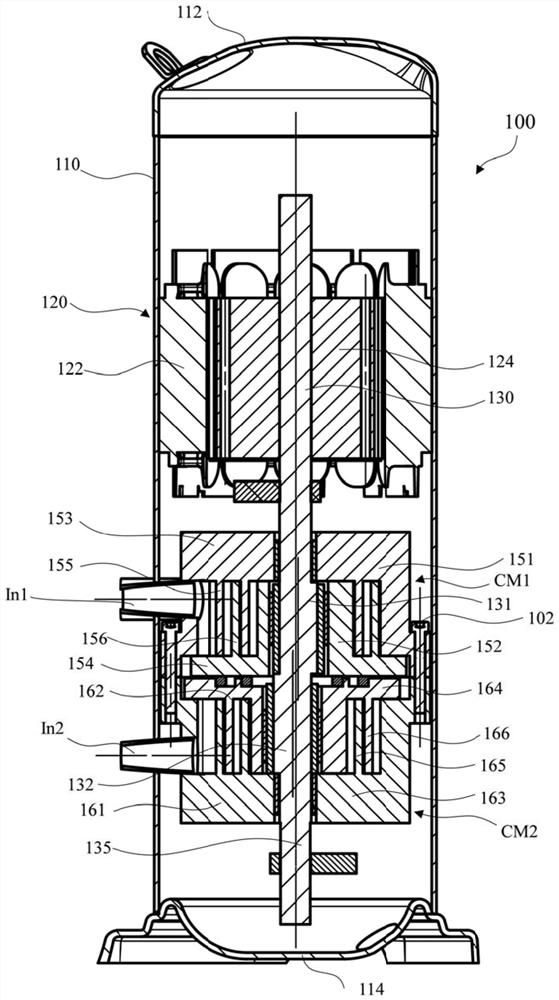

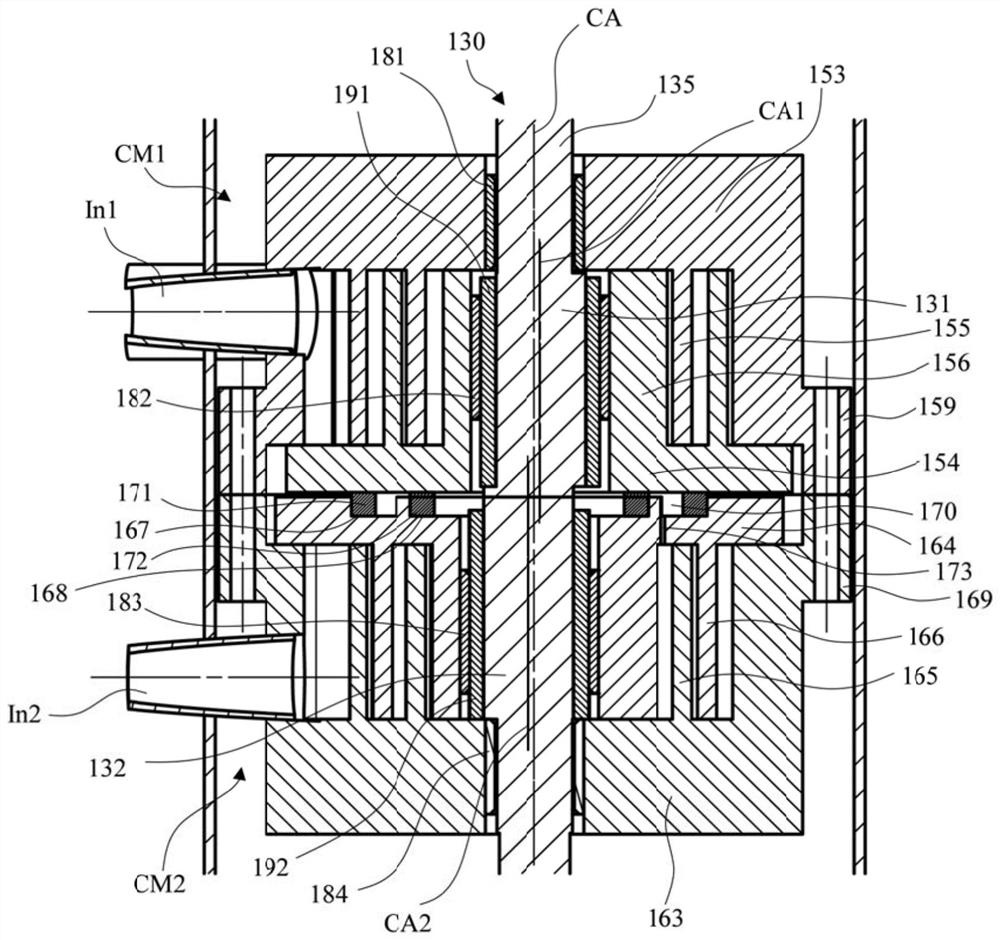

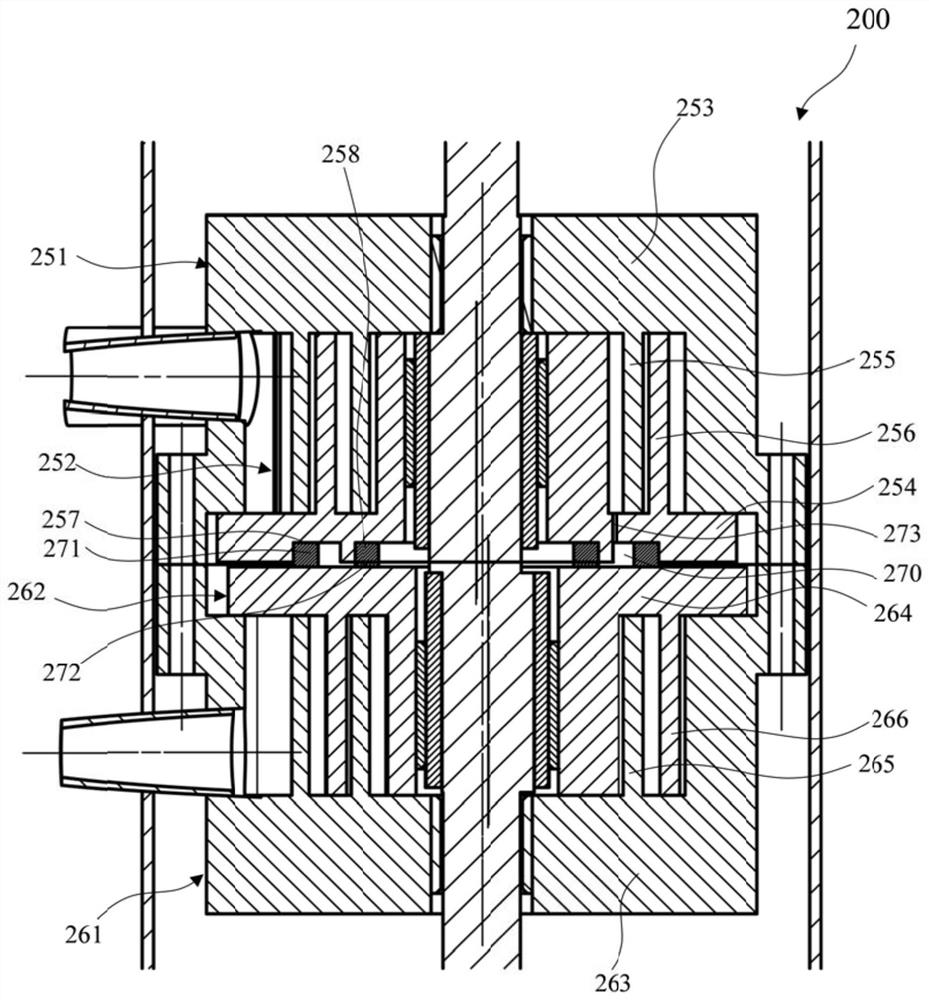

[0046] figure 1 is a schematic longitudinal section of a scroll compressor according to an embodiment of the present disclosure; figure 2 Yes figure 1 A partially enlarged schematic diagram of the compression mechanism of the scroll compressor. The following will refer to figure 1 and figure 2 The scroll compressor according to the present disclosure will be described.

[0047] like figure 1 and figure 2 As shown, the scroll compressor 100 includes a casing 110 , a top cover 112 disposed at one end of the casing 110 and a bottom cover 114 disposed at the other end of the casing 110 . Housing 110. Top cover 112 and bottom cover 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com