Feeding vehicle for non-ferrous metal smelting

A technology for non-ferrous metals and feeding trucks, applied in lighting and heating equipment, furnaces, furnace types, etc., can solve the problems of difficult to control the amount of fillers, low safety, affecting smelting, etc., to improve the uniformity of feeding, improve Efficiency and safety improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

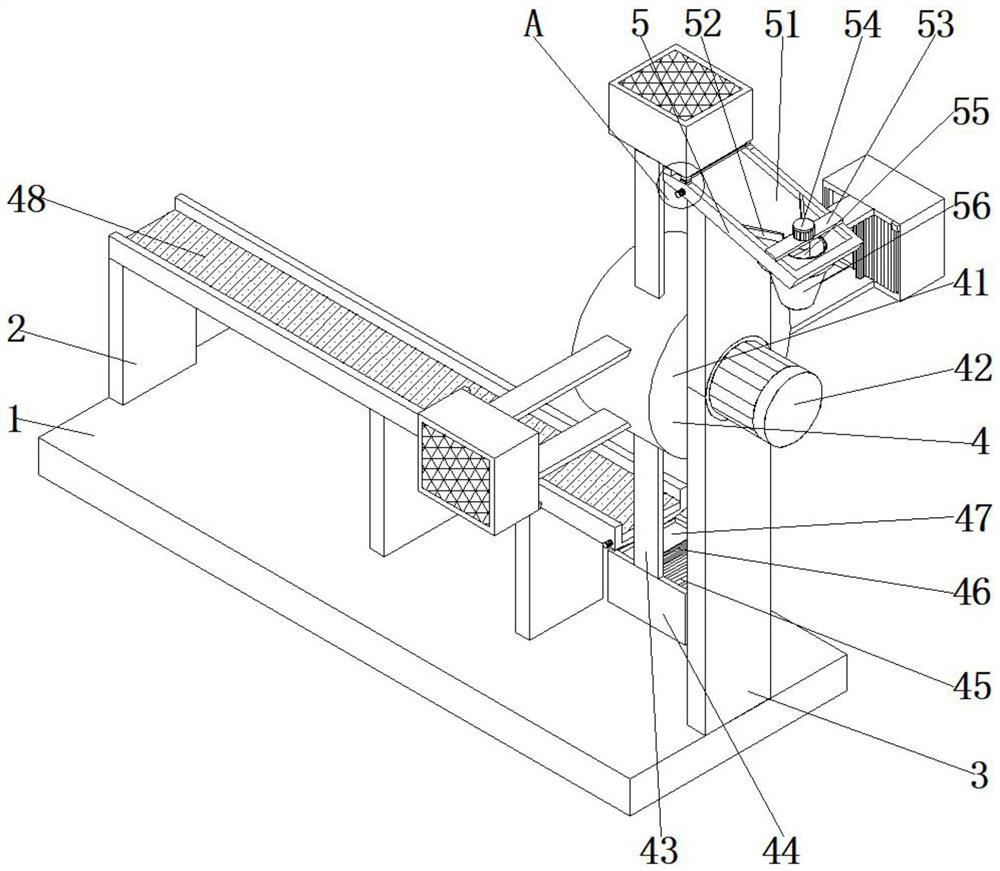

[0032] see Figures 1 to 6 , in the embodiment of the present invention, a kind of charging truck for non-ferrous metal smelting, comprising:

[0033] base plate 1, used to install the support device;

[0034] The first support leg 2, used to support and install the feeding belt 48, is located at one end of the top of the base plate 1, and is fixedly connected to the top of the base plate 1;

[0035] The main support column plate 3, used for installing and connecting the feeding mechanism and the feeding mechanism, is located at the other end of the top of the base plate 1, and is fixedly connected to one end of the top of the base plate 1;

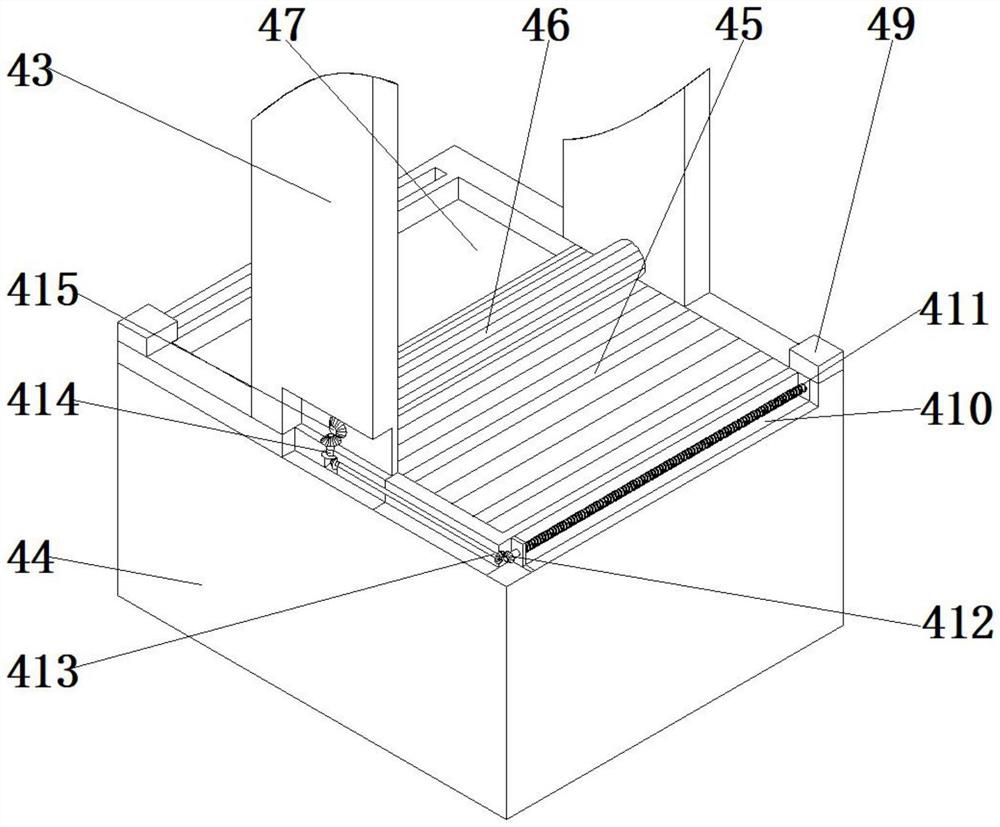

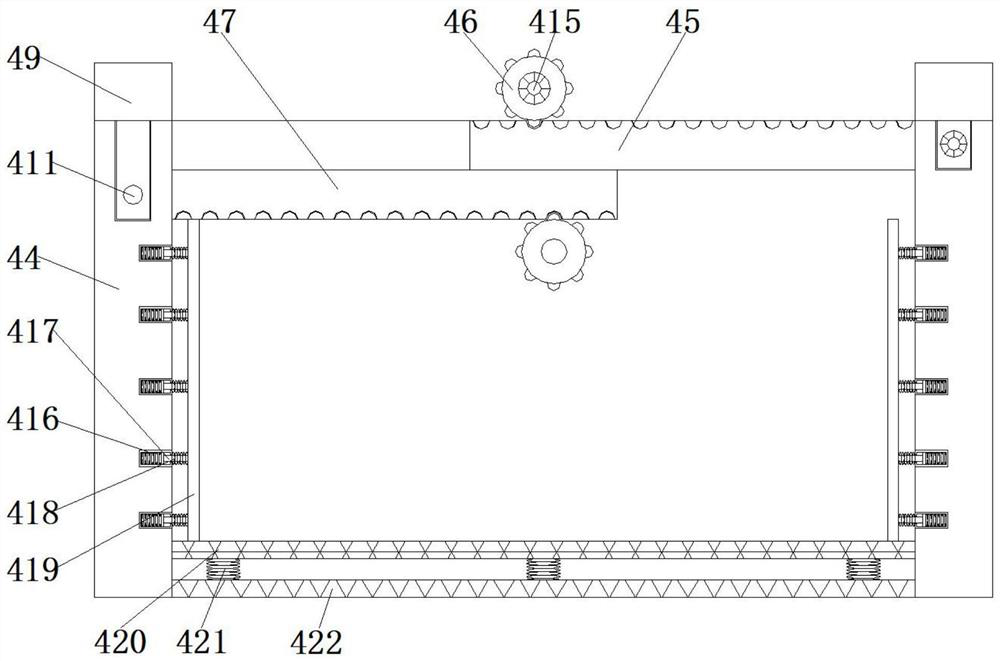

[0036] The feeding mechanism 4 is used for feeding and screening non-ferrous metal ore slag and dust, and is located at one end of the main support column plate 3;

[0037] The feeding mechanism 5 is used for filling the smelting furnace, and is located at the top of the main support column plate 3;

[0038] The retracting and pulling ...

Embodiment 2

[0044] Please refer to figure 1 and Figure 4 The feeding mechanism 5 includes a feeding trough plate 51, the top of the main support column plate 3 is fixedly connected with one end of the bottom end of the feeding trough plate 51, and the middle part of the inner side of the feeding trough plate 51 is fixedly connected with a drainage inclined plate 52. In order to guide the sliding trajectory of the metal ore, one end of the inner side of the feeding chute plate 51 is fixedly connected with an installation connection cavity 58, the inner wall of the inner side of the installation connection cavity 58 is fixedly connected with a return spring 57, and the inner side of the return spring 57 is fixedly connected with the feeding material. The top of the funnel 56 is fixedly connected with a sealing ring plate 59 on the inner top of the installation connection cavity 58 , the top of the feeding funnel 56 is slidably connected with the bottom end of the sealing ring plate 59 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com