Automatic separating and screening device for chemical fertilizer production

An automatic separation and screening device technology, applied in the direction of solid separation, filtration, chemical instruments and methods, etc., can solve the problems of single function, inability to reduce device noise, inability to filter compound fertilizers, etc., and achieve scientific and reasonable structure, safe and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

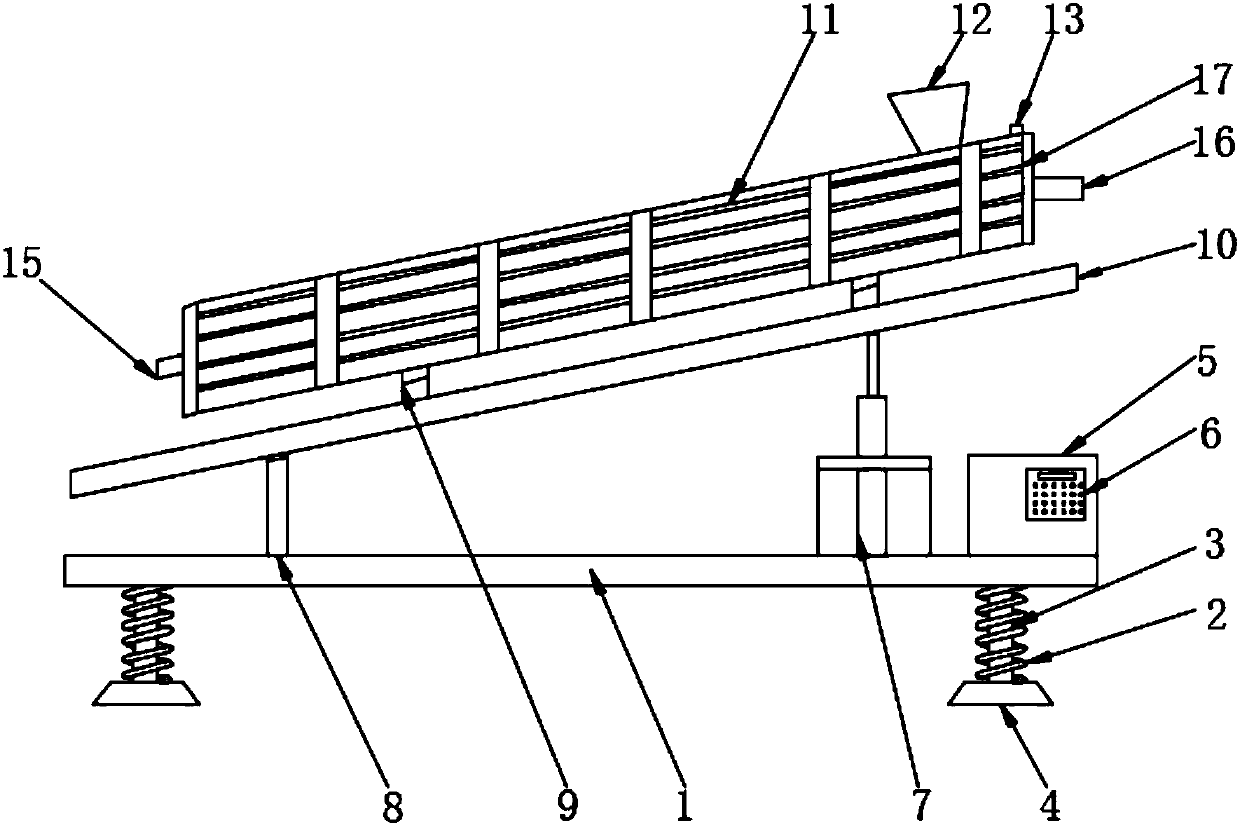

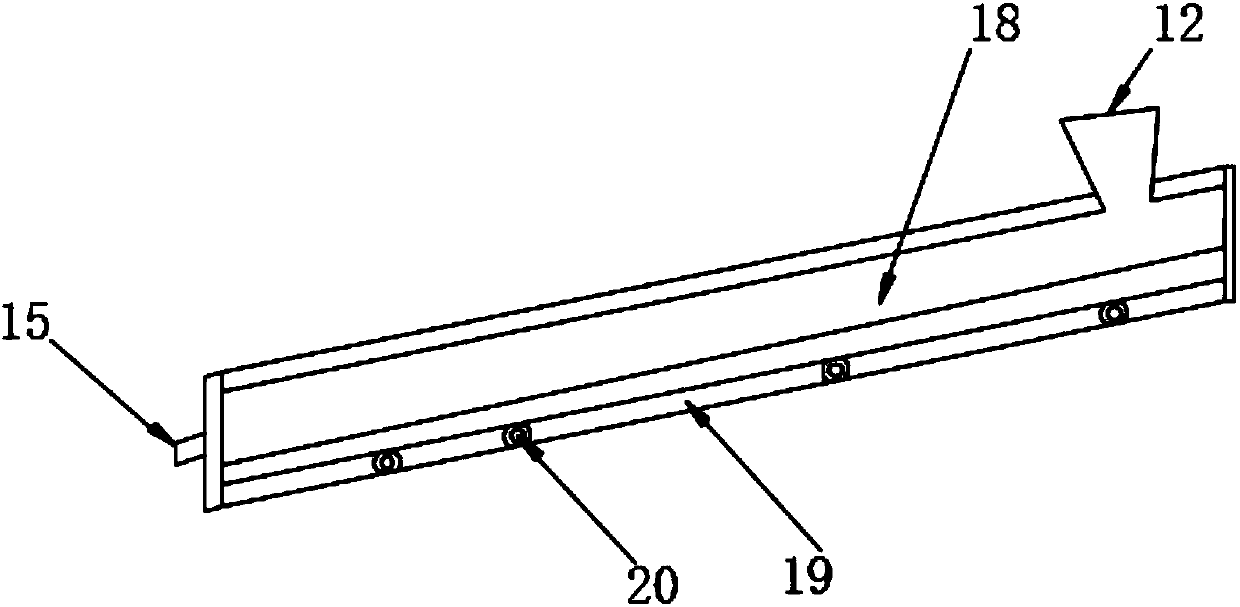

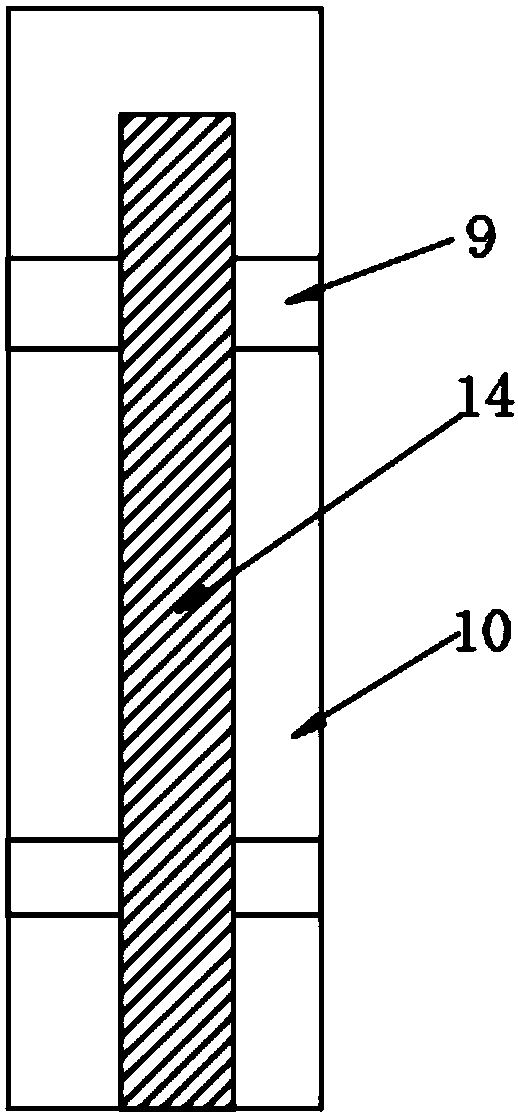

[0018] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, an automatic separation and screening device for chemical fertilizer production, including a support platform 1, a shock absorbing spring 2, a support fiber rod 3, a rubber base 4, a protective box 5, a control switch 6, and a hydraulic device 7 , support rod 8, vibrator 9, support 10, protective shell 11, feed port 12, exhaust port 13, groove 14, handle 15, tension rod 16, place plate 17, inner mold 18, screen 19 and pulley 20. Shock-absorbing springs 2 are installed at the four corners of the bottom end of the support platform 1. A support fiber rod 3 is installed inside the shock-absorption spring 2. A rubber base 4 is installed at the bottom end of the support fiber rod 3. A protective box is installed on the top right of the support platform 1. 5. A control switch 6 is installed inside the protective box 5, a hydraulic device 7 is installed on the left side of the protective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com