Self-adaptive detector for detecting structural performance of prefabricated part

A technology for structural performance and prefabricated components, which is used in the testing of machine/structural components, elasticity testing, and testing the strength of materials by applying stable tension/pressure, which can solve problems such as the inability to adjust the applied load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

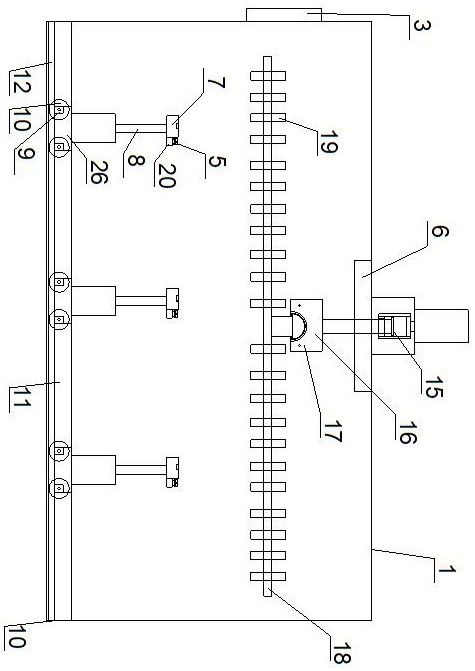

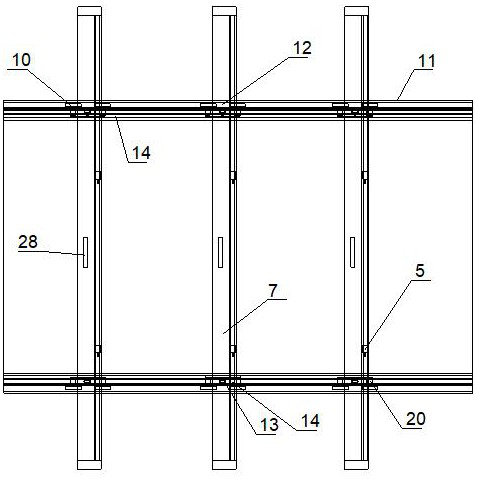

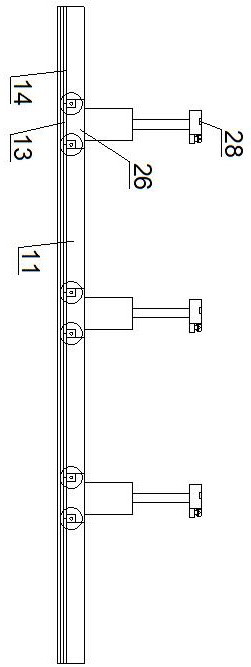

[0027] like figure 1 As shown, an adaptive detector for the detection of the structural performance of prefabricated components includes a frame 1 , a microcontroller 3 , a support system 4 , a displacement sensor 5 and a loading system 6 . The microcontroller 3 is arranged on the side of the rack 1 . The support system 4 includes three support beams 7 and electric lifting rods 8 . The bottom surface of the electric lift rod 8 is provided with a base 26 , a servo motor 9 is set in the base 26 , and the servo motor 9 is connected to the roller 10 . The lifting rod guide rail 11 is arranged at the bottom of the rack 1 . The loading system 6 includes an electronic servo press 15 and a load distribution beam 18 on the top of the frame 1 . The microcontroller 3 is electrically connected with the electric lift rod 8 , the electronic servo press 15 and the servo motor 9 . A pressure sensor 16 is provided on the top surface of the indenter 17 of the electronic servo press 15 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com