Jack positioning convenient packaging method for mushroom nails and products with similar shapes thereof

A packaging method and hole positioning technology are applied in the field of convenient packaging for mushroom nails and products of similar shapes, and can solve problems such as unfavorable energy saving and environmental protection, inability to form, and occupy a large space, so as to improve labor productivity, improve packaging efficiency, The effect of increasing the number of packages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The convenient packaging method for positioning the sockets of mushroom nails and products with similar shapes, including the following steps:

[0014] Step 1: Insert the product into the non-centrally symmetrical jack on the square trapezoid cardboard, and place one of the square trapezoid cardboards with the product inserted into the bottom of the square box. The sides stand separately on the sides;

[0015] The remaining four-sided square trapezoid cardboards are four separate or two conjoined or one whole; each has its own advantages and disadvantages, four separate pieces only need to open one lining mold, but they need to be placed on four sides at the same time, and one hand needs to be held at the same time. Two; one is easy to place as a whole, but the cost of the mold is too high, which also causes waste of cardboard.

[0016] Step 2: Then put the sixth cardboard on top and close the lid of the box.

Embodiment 2

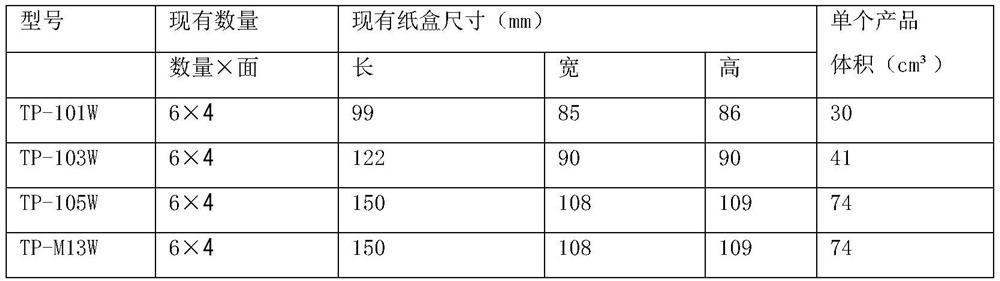

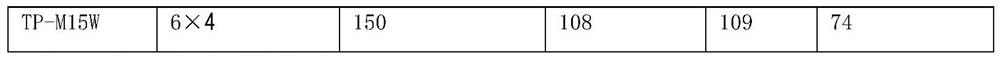

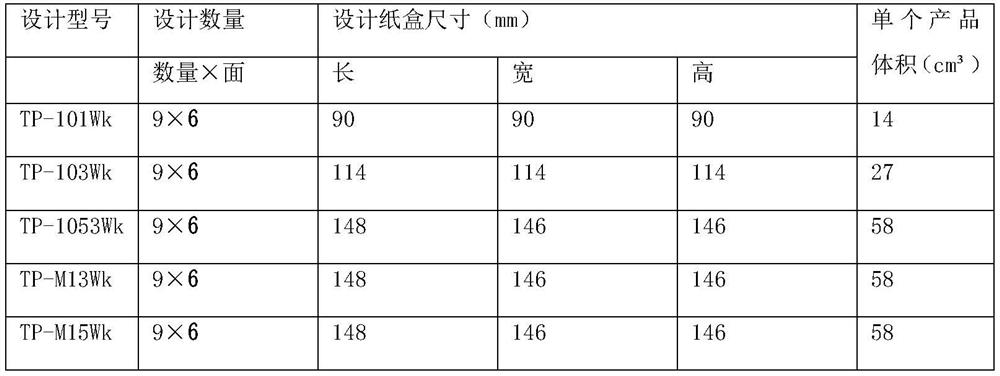

[0018] Take TP-105W, TP-M13W, TP-M15W as examples, now each box contains 24 pieces.

[0019]

[0020]

[0021] The volume of a single product packaged by this method

[0022]

[0023] The reduction ratio varies depending on the size and length

[0024]

[0025] The following table is another series, reduced more, from 63CM3 to 27CM3

[0026]

[0027] The design asymmetric jack of the present invention statically solves the problem of mutual interference, obstruction and adhesion of XYZ three directions in the same size space, but does not solve the problem of avoiding mutual interference, obstruction and adhesion of XYZ three directions in dynamic packaging. The six single-sided jack cardboards solve the problems of mutual interference, obstruction and sticking in the XYZ three-way dynamic packaging in the same size space, but do not solve the problem of fixed placement of single-sided cardboards. The structure of single-sided cardboard solves the problem of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com