Intelligent roller service life testing machine

A life test and intelligent technology, which is applied in the testing of mechanical components, testing of machine/structural components, instruments, etc., can solve problems such as easy to cause industrial injuries, difficult to accurately achieve force values, unstable force values, etc., to achieve reliable The effect of high precision and avoiding sudden failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

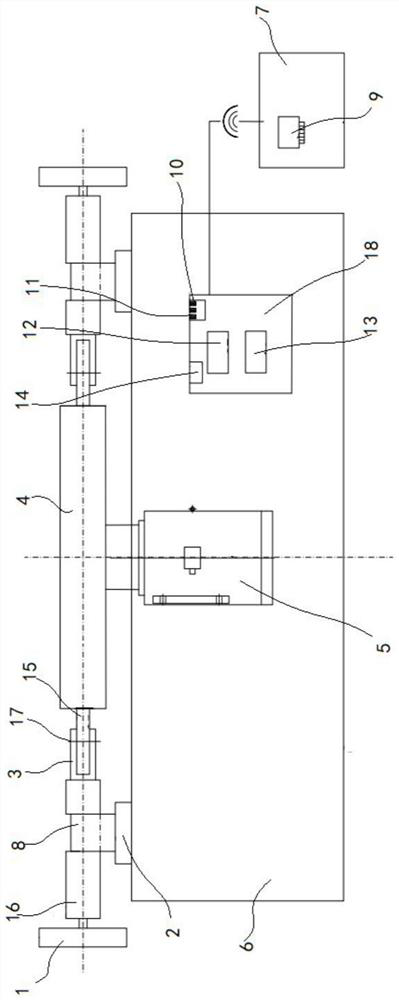

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0024] see figure 1 , An intelligent roller life testing machine shown in the figure includes a test bench 6, and the test bench 6 can be a frame structure or other structures.

[0025] A motor 5 is installed in the middle position of the test stand 6 , and the motor 5 may be a common motor or a variable frequency motor. A test turntable 4 is fixed on the output shaft of the motor 5. After the motor 5 is started, the test turntable 4 is driven to rotate.

[0026] The roller installation device of the present invention can be one set, two sets, or even multiple sets, so that the life test can be performed on one roller 15 to be tested at the same time, and the life test can also be performed on multiple rollers 15 to be tested at the same time. If there are two or more sets of roller mounting devices, these roller mounting devices are distribu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap