Method for improving evaporation and concentration efficiency of salt pan

An evaporative concentration and efficiency technology, which is applied in the field of improving the evaporation and concentration efficiency of salt fields, can solve the problems of reducing the evaporation rate of salt fields, the poor hydrophilicity of plastics, and reducing the evaporation area, so as to achieve strong operational feasibility and increase the effective evaporation area. , the effect of increasing the evaporation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

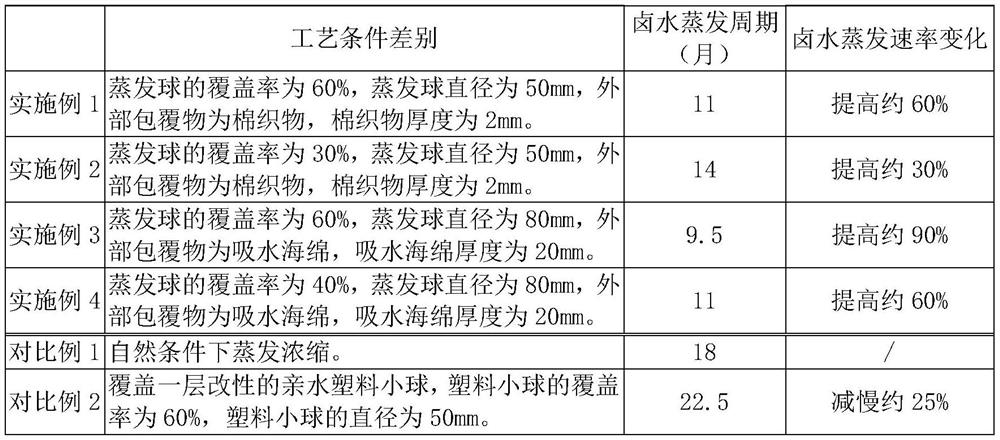

Embodiment 1

[0025] A salt lake uses the precipitation method to extract lithium. A layer of evaporation balls is placed in the pre-concentration tank. The coverage of the evaporation balls is 60%, the diameter of the evaporation balls is 50mm, and the outer covering of the evaporation balls is a small cotton bag. , the thickness of the small cloth bag is 2mm. The evaporation period of brine is about 11 months, and the evaporation rate of brine is increased by about 60%.

Embodiment 2

[0027] A salt lake uses the precipitation method to extract lithium. A layer of evaporation balls is placed in the pre-concentration tank. The coverage of the evaporation balls is 30%, the diameter of the evaporation balls is 50mm, and the outer covering of the evaporation balls is a small cotton bag. , the thickness of the small cloth bag is 2mm. The evaporation period of brine is about 14 months, and the evaporation rate of brine is increased by about 30%.

Embodiment 3

[0029] A salt lake uses the precipitation method to extract lithium. A layer of evaporation balls is placed in the pre-concentration tank. The coverage rate of the evaporation balls is 60%. The diameter of the evaporation balls is 80mm. The outer coating of the evaporation balls is a water-absorbing sponge. The thickness is 20mm. The evaporation period of brine is about 9.5 months, and the evaporation rate of brine is increased by about 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com