Compensation method for grinding and polishing flexible wheel of robot

A compensation method and a flexible wheel technology, applied in the polishing field, can solve the problems of difficult polishing of polishing workpieces, and achieve the effect of convenient use and inconvenient changes in polishing force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

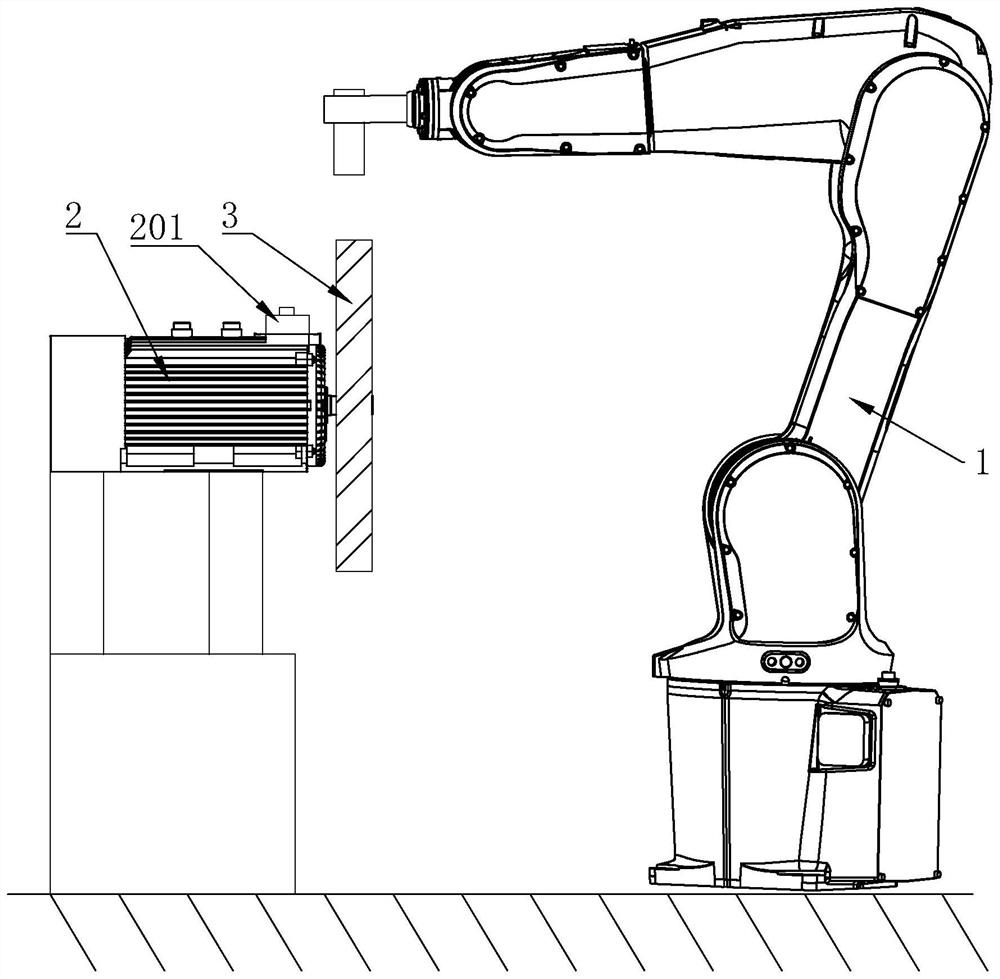

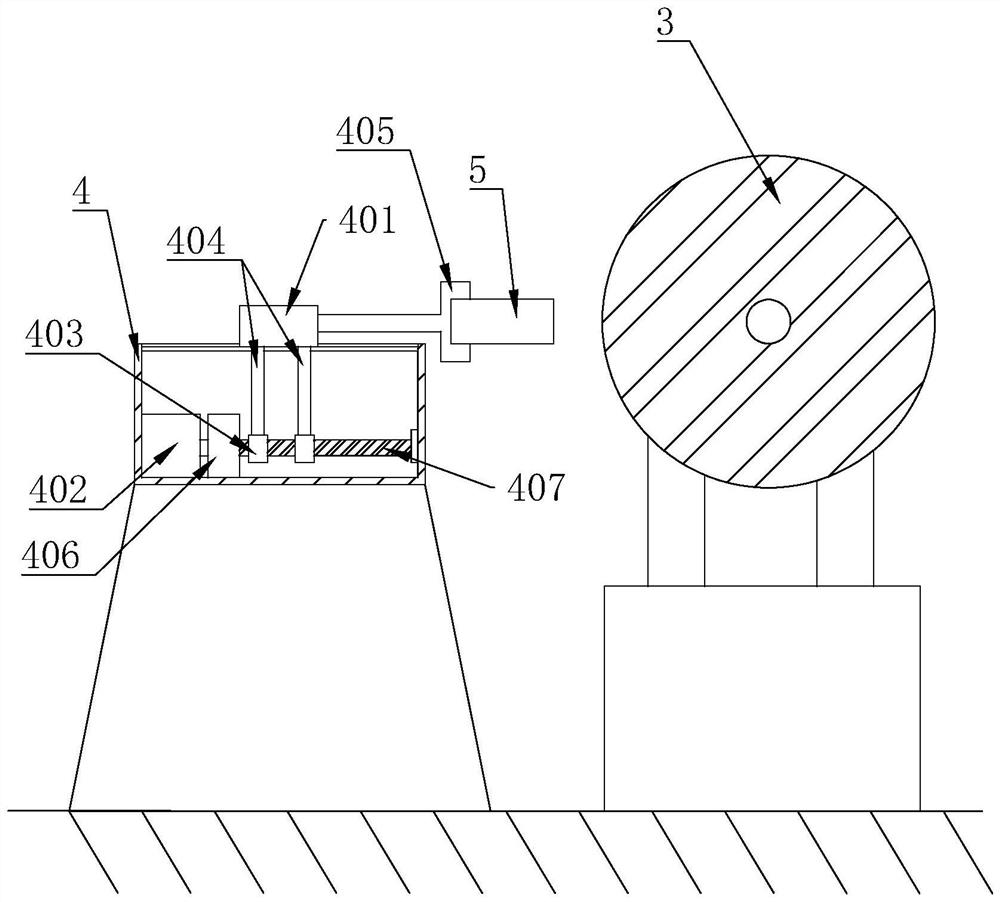

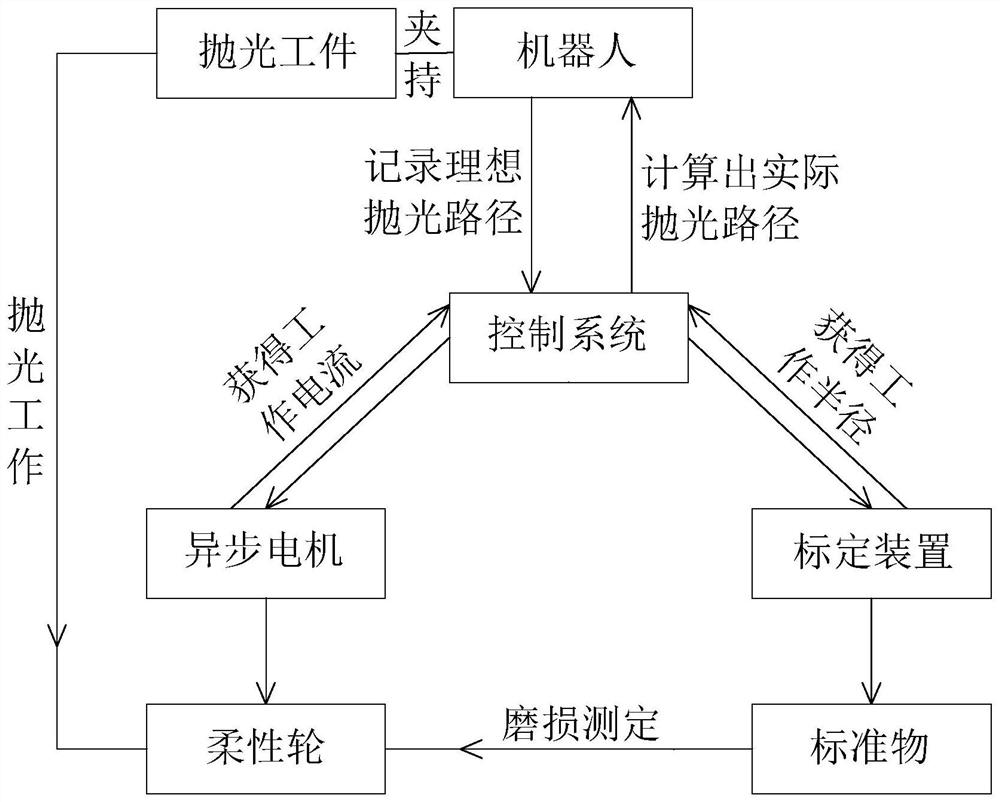

[0033] The present invention will be further described in detail below with reference to the accompanying drawings.

[0034] First of all, the coordinate values in the ideal path program and the actual path program of the robot in this embodiment are set according to the initial coordinate system. The establishment of the initial coordinate system is to control the robot to clamp the workpiece to reach the corresponding flexible wheel through the teach pendant. On the polishing point, and the polishing point is the origin, a space rectangular coordinate system of XYZ three axes is established. This coordinate system is the initial coordinate system. All coordinate values and offsets of coordinate values in the program are obtained according to the initial coordinate system.

[0035] This embodiment discloses a robot flexible wheel grinding and polishing compensation method, which includes the following steps:

[0036] a. The PLC control system sets the parameters, starts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com