Novel two-stage vibration isolation two-dimensional adjustable suspension system for electric automobile

An electric vehicle and suspension system technology, applied in the field of auto parts, can solve the problems of complex structure, insufficient vibration isolation adjustment, low integration, etc., and achieve high integration, improve high frequency vibration isolation performance, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

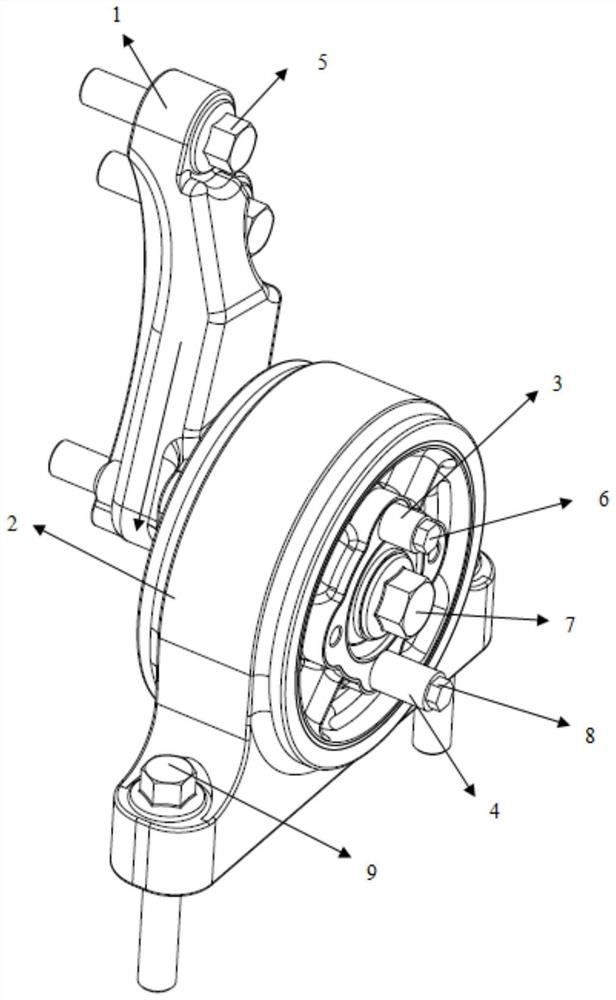

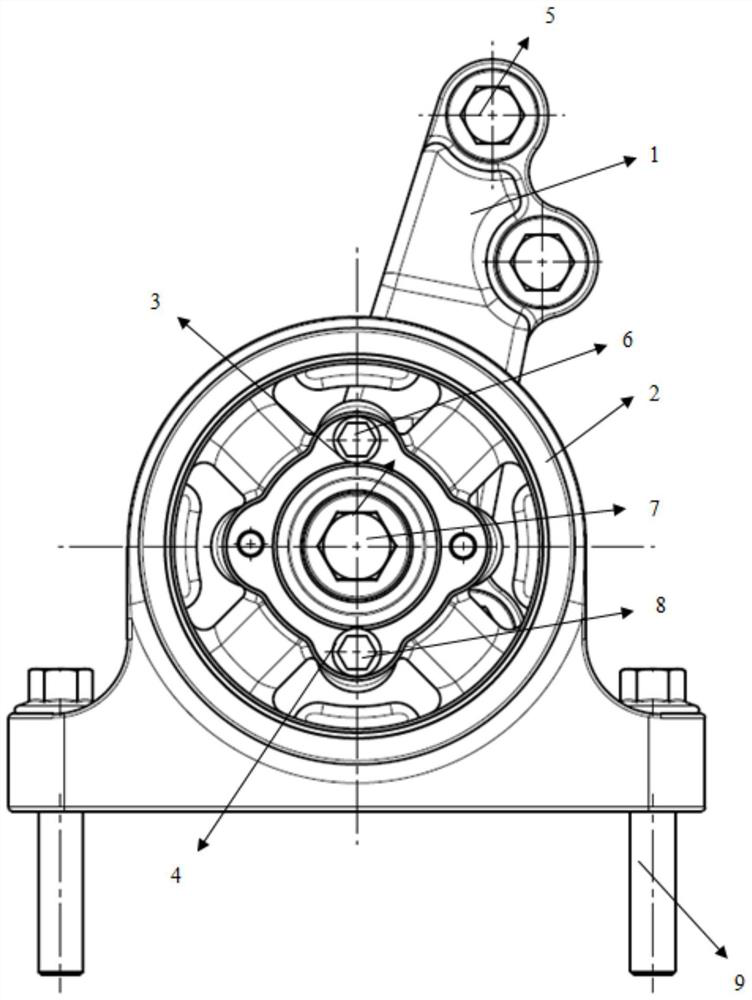

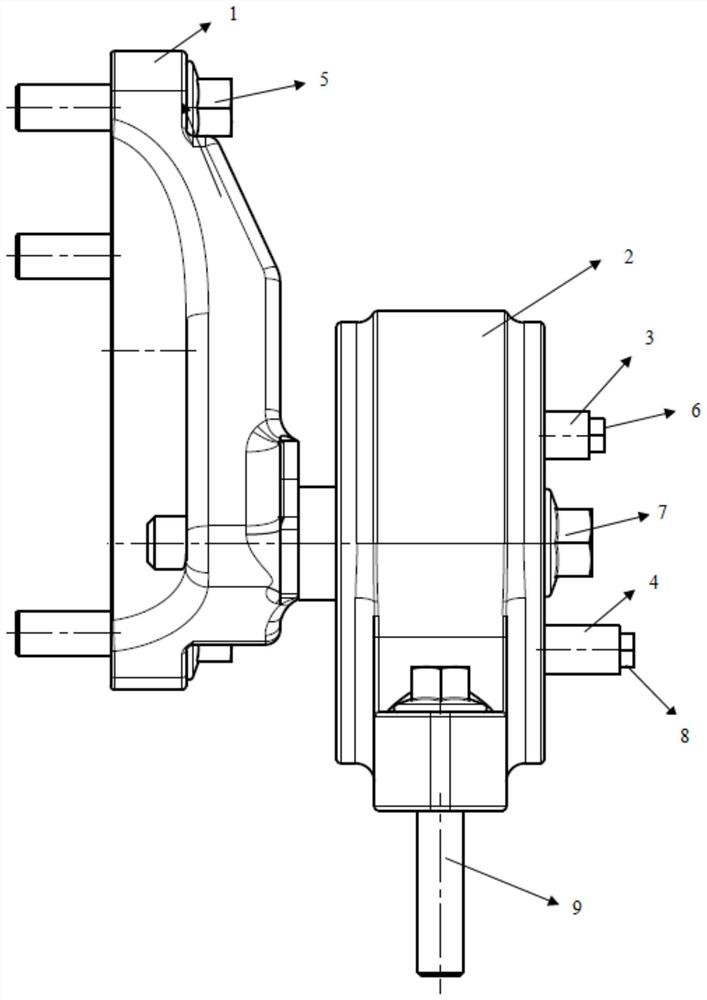

[0022] as attached figure 1 to the attached Figure 4 As shown, the present invention provides a novel two-dimensional adjustable suspension system for secondary vibration isolation of electric vehicles, which includes a suspension bracket 1, a suspension 2 and a counterweight. The top of the suspension bracket 1 is installed with an A-bolt 5, and The motor is connected by A bolt 5, C bolt 7 is installed at the bottom of the suspension bracket 1, and the suspension 2 is installed on the suspension bracket 1 through the C bolt 7; 11. Suspension intermediate casing 12, suspension outer rubber bushing 13, suspension housing 14 and suspension outer rubber bushing casing 15 are composed of suspension inner casing 10, suspension inner rubber bushing 11, suspension The intermediate casing 12 and the suspension outer rubber bushing 13 are arranged in sequence from the inside to the outside, the suspension outer rubber bushing 13 is arranged in the suspension outer rubber bushing casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com