Motor suspension

A technology for suspending and driving motors, used in electric power units, power units, mechanical equipment, etc., can solve the problems of low rubber stiffness, inability to overcome high-frequency hardening of rubber, and failure to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0056] This embodiment provides a motor suspension for absorbing and blocking the high-frequency vibration and high-frequency howling noise emitted by the driving motor of an electric vehicle suspended on the vehicle frame, especially the high-frequency vibration and high-frequency howling noise above 800 Hz. place.

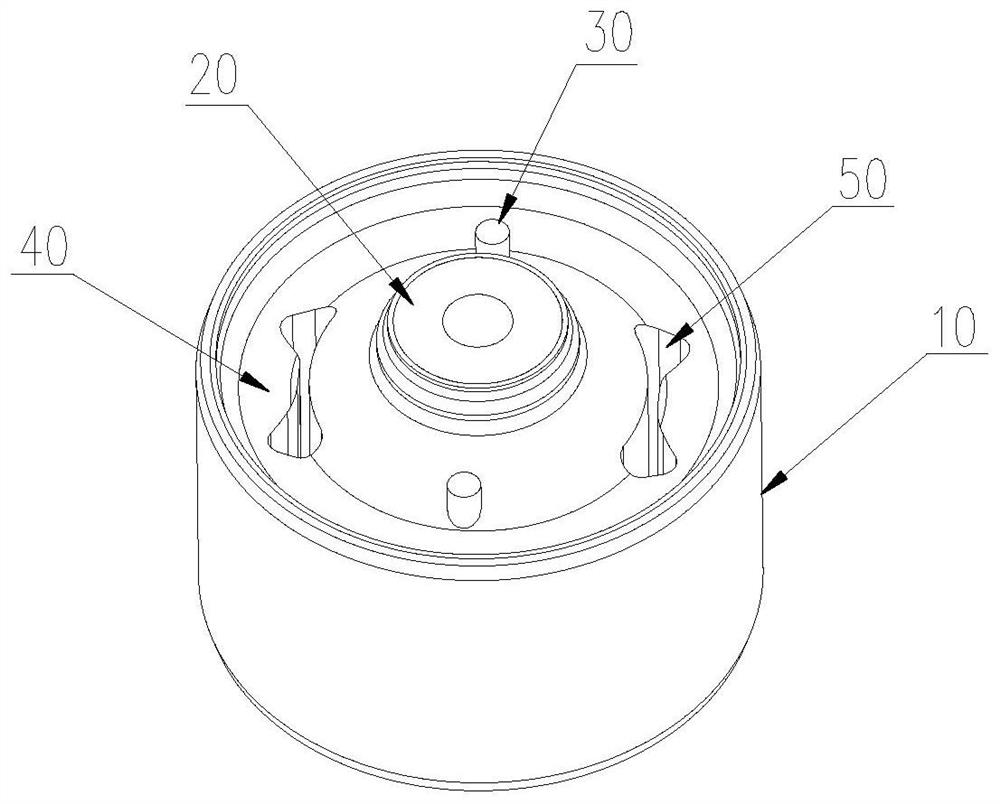

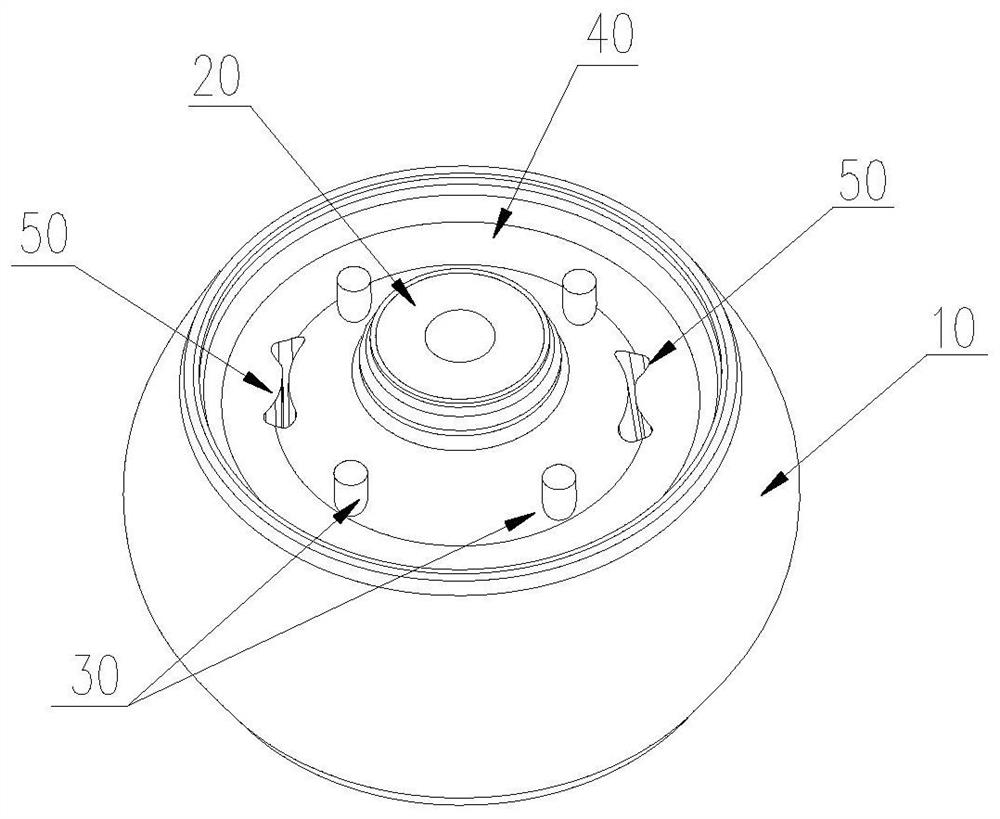

[0057] Such as figure 1 A schematic diagram of a three-dimensional structure of a columnar motor suspension provided by an embodiment of the present invention, figure 2 A three-dimensional structural schematic diagram of a drum-shaped motor suspension provided in an embodiment of the present invention is shown in the following figure:

[0058] A motor mount provided in this embodiment includes:

[0059] Sheath 10, core tube 20, resonant mass 30 and rubber body 40;

[0060] Sheath 10 as figure 1 shown as a hollow cylinder, or as figure 2 Shown as a hollow drum.

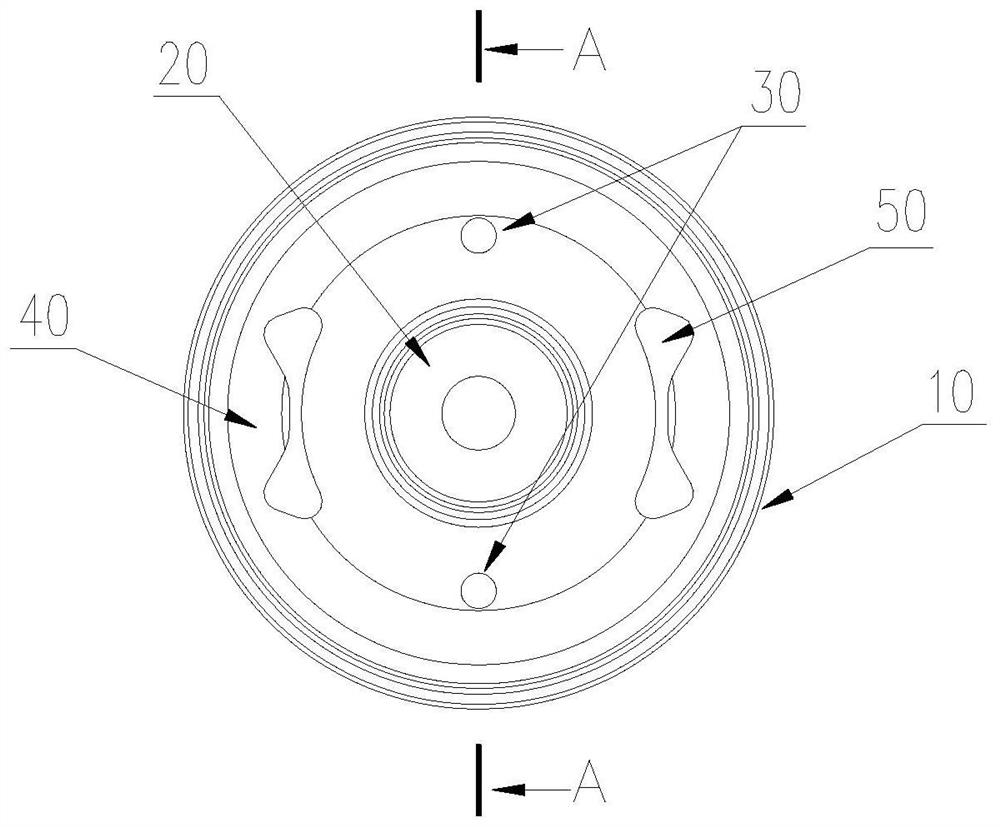

[0061] Such as image 3 A schematic top view structure diagram of a columnar motor suspension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com