Flexible mechanical-hydraulic coupling device between medium and heavy-duty power plant and installation foundation

A power device and installation foundation technology, which is applied in the field of flexible mechanical hydraulic coupling devices, can solve the problems of small load capacity of liquid-resistance vibration isolators, damage to decoupling mechanisms, and limited low-frequency damping, so as to avoid high-frequency dynamic hardening , prevent structural damage, and improve the effect of low-frequency damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

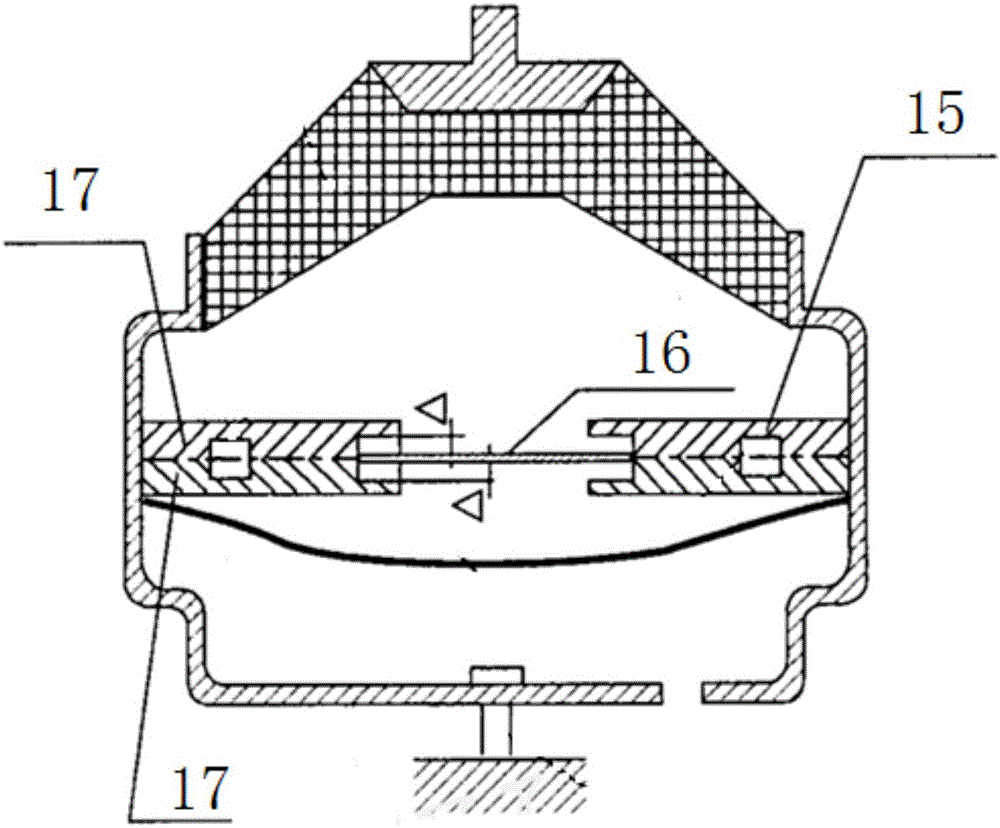

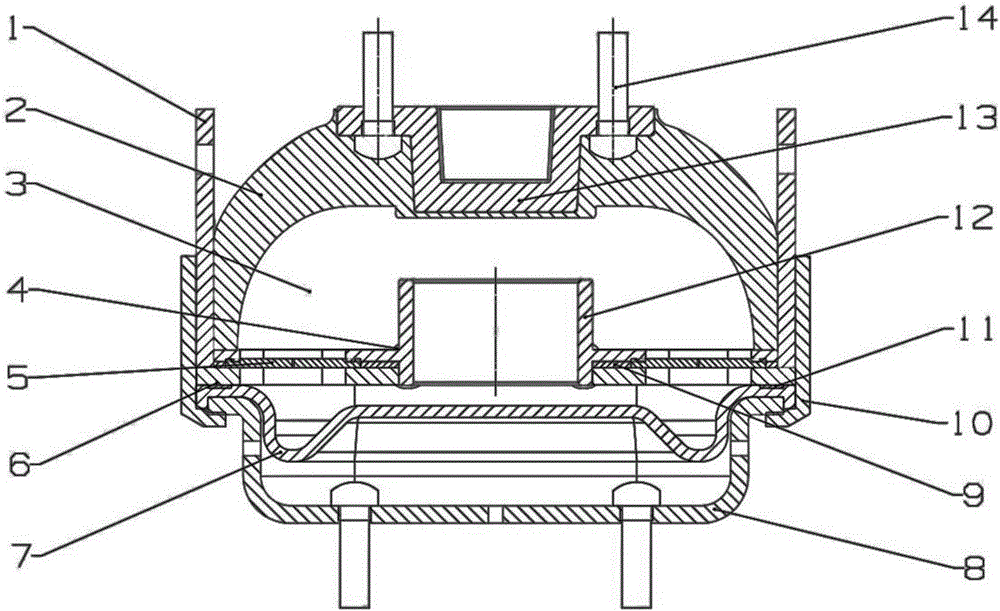

[0029] Such as figure 2 As shown, a flexible mechanical-hydraulic coupling device between a medium and heavy-duty power unit and an installation foundation includes a rubber main spring assembly, and the rubber main spring assembly includes an upper body 1 of the casing, the upper part of the upper body 1 of the casing protrudes upwards, and the outer side The lower part is fixedly connected with several connecting plates 10, and the lower ends of the connecting plates 10 protrude from the lower edge of the upper body 1 of the housing; Vulcanized together to form the rubber main spring assembly. The middle part of the upper frame 13 protrudes downwards and is located at the center of the rubber main spring 2. The head of the bolt 14 is vulcanized inside the rubber main spring 2, and the screw rod passes through the through holes on both sides of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com