Tower cable tightening device with tension monitoring function for power construction

An electric power construction and cable technology, applied in the field of tower cable tightening devices, can solve the problems of cable breakage, economic loss, uncontrollable force in the cable tightening process, etc., to achieve convenient operation and avoid economic losses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

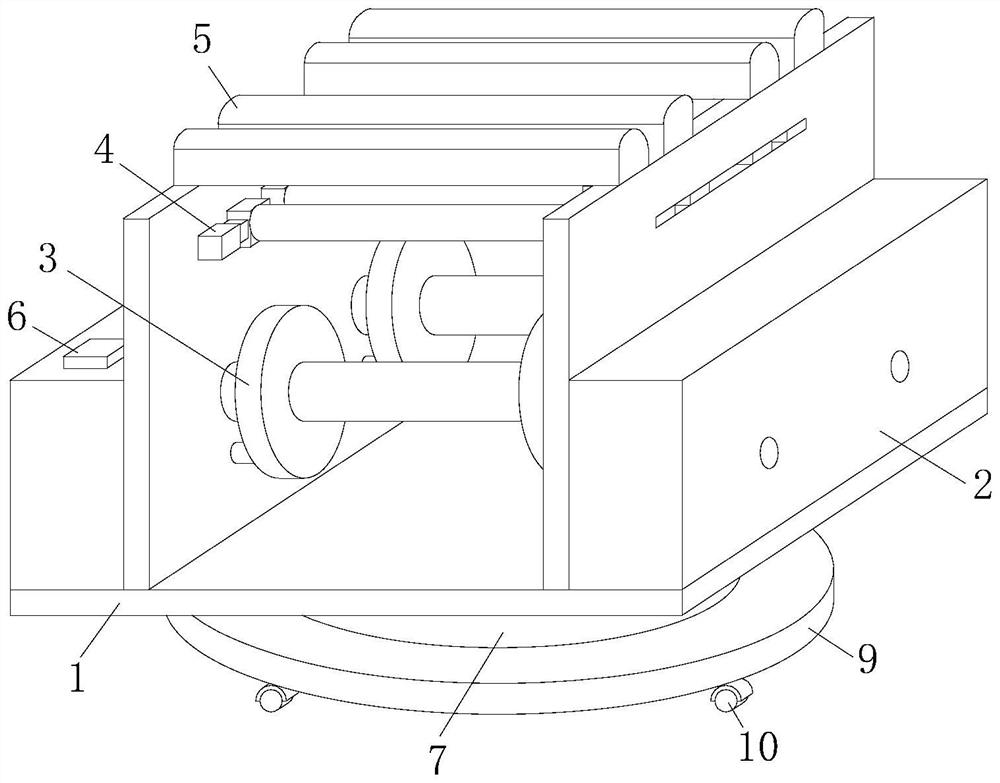

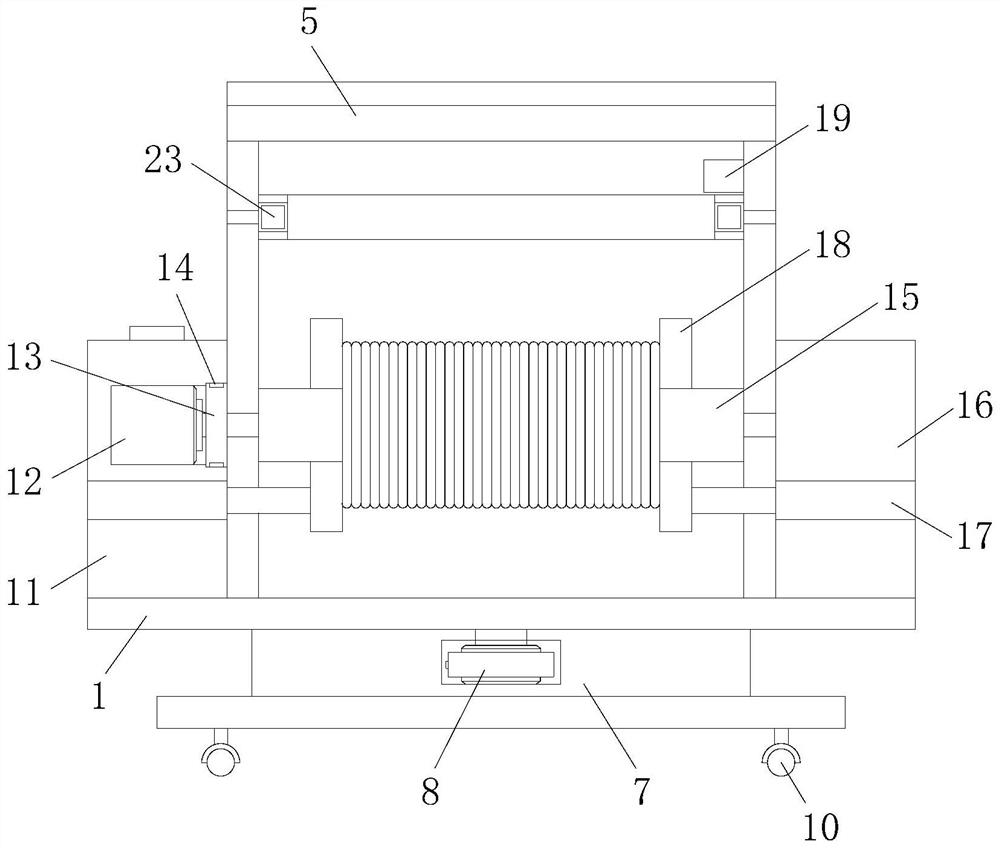

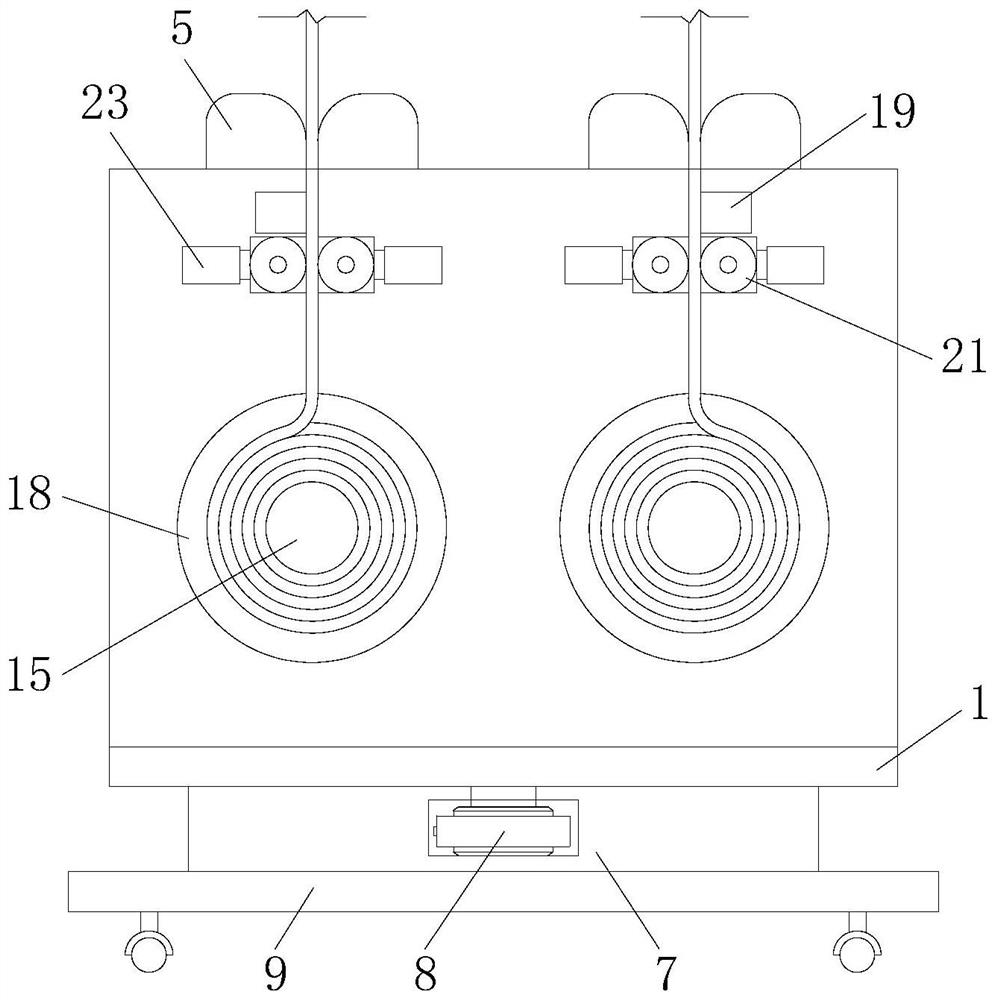

[0024] The specific embodiment is a tower cable tightening device with a tension monitoring function for electric power construction, and its structural diagram is as follows figure 1 shown, its sectional view is as figure 2 shown, its side section is shown in image 3 As shown, the device includes a fixing frame 1, a driving module 2 arranged on the outside of the fixing frame 1 for driving the cable to tighten, and an adjusting module 3 arranged on the inner side of the fixing frame 1 for adjusting the overall tightening width of the cable; the adjustment module 3. The upper side is provided with a fixing module 4 for fixing the position of the cable, the upper side of the fixing module 4 is provided with a tension sensor 19 for monitoring the tensile force, the upper side of the fixing frame 1 is provided with a material guide plate 5 for guiding the cable, and the driving module 2 The upper side is provided with a control panel 6 for control, the lower side of the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com