Preparation process of multicolor epoxy terrazzo floor

A preparation process and multi-color ring technology, which is applied in the field of multi-color epoxy terrazzo floor preparation technology, can solve the problems of large difference in size of adjacent color spots, single color tone, and large local color difference on the terrazzo floor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

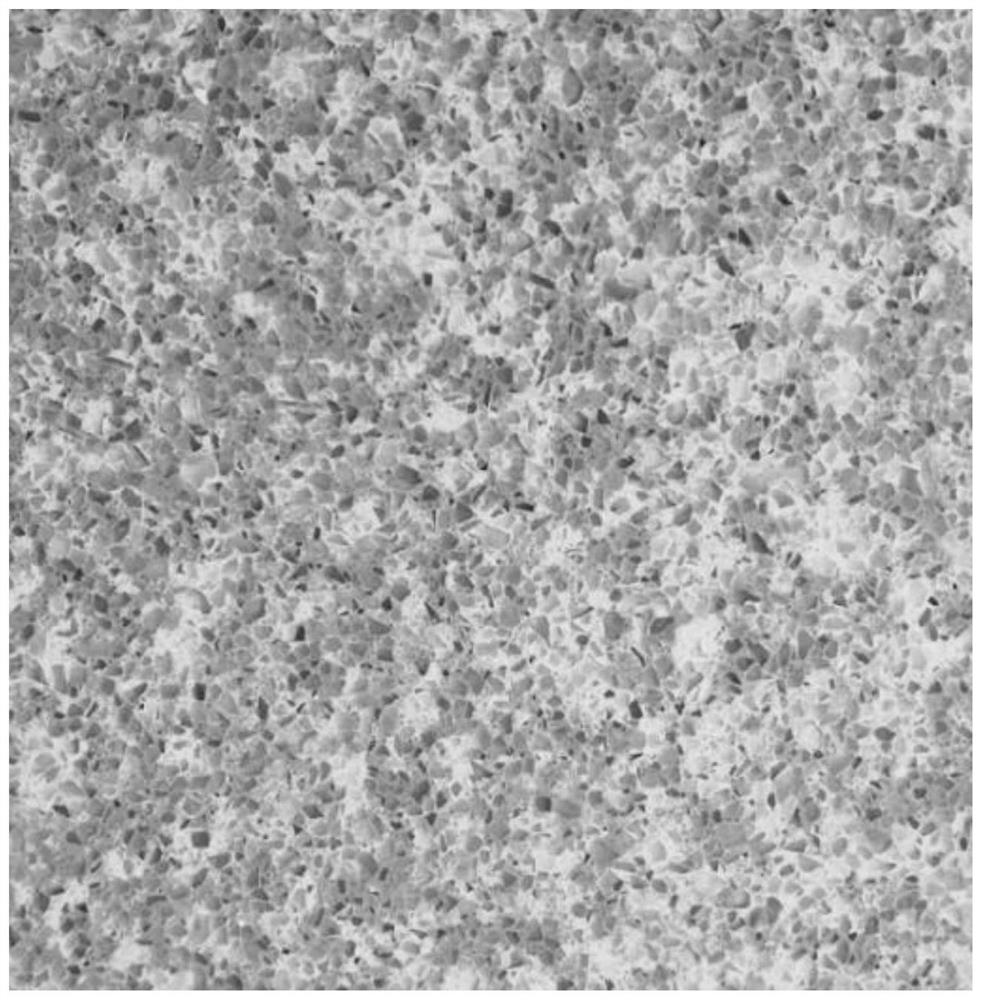

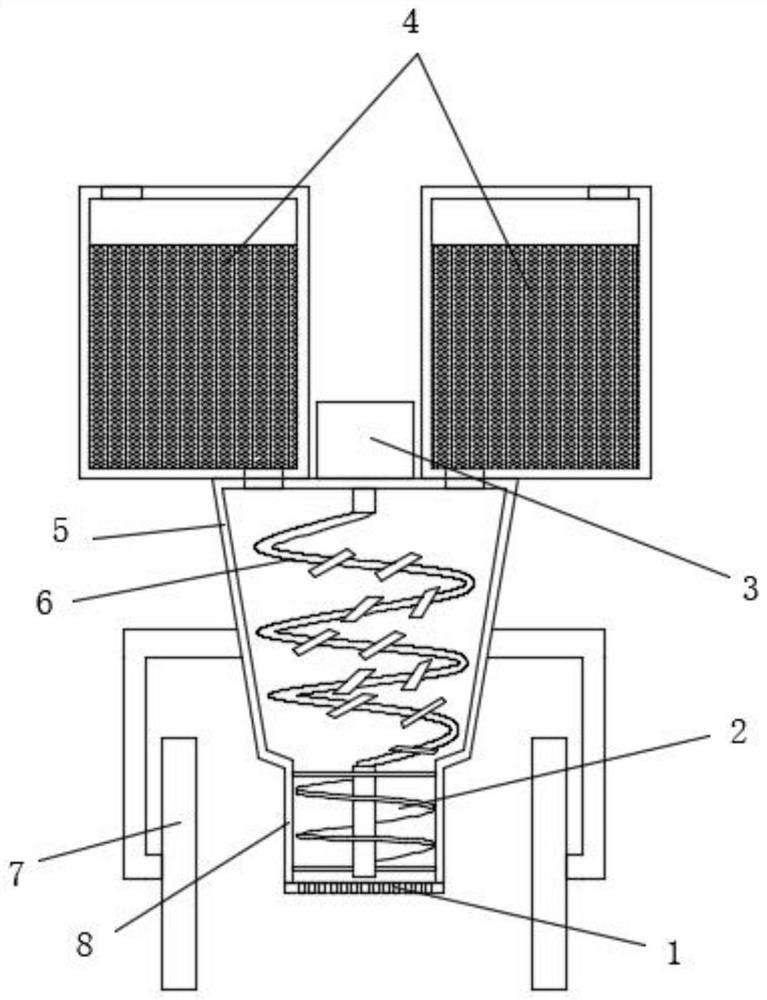

[0027] refer to Figure 1-2 , a multi-color epoxy grinding stone floor preparation process, comprising the following steps:

[0028] s1, fully mixing the first millstone slurry and the first color paste to obtain product A, and fully mixing the second millstone slurry and the second color paste to obtain product B;

[0029] s2, simply mixing product A and product B to obtain product C;

[0030] s3, product C is sieved through the screen to obtain product D;

[0031] s4. Spread the product D on the ground, scrape it flat and pat it tightly;

[0032] s5. After the product D is cured, rough grinding, fine grinding and overcoating are performed.

[0033] In this process, firstly, uniformly mixed product A and product B are prepared. Since product A is obtained by fully mixing the first millstone slurry and the first color paste, the final slurry of product A is pure color. Similarly, the final slurry of product B is The color of the product is also a solid color, and the produ...

Embodiment 2

[0035] refer to Figure 1-3 , a multi-color epoxy grinding stone floor preparation process, comprising the following steps:

[0036] s1. Fully mixing the first millstone slurry and the first color paste to obtain a product A, and fully mixing the second millstone slurry and the second color paste to obtain a product B, the product A includes: accounting for 20-25% Specification 4 -6-mesh white glass, 3-5% specification 6-8 mesh white glass, 10-15% specification 10-20 mesh white glass, 0.7-1% specification 6-8 mesh lens, 3 -5% specification 16-30 mesh lens, 15-20% specification 7-140 mesh quartz sand, 25-35% specification 325 mesh quartz powder, 9-10% resin, 0.17-0.18 % white paste, 0.001% carbon black paste, 0.0014% medium yellow paste, the above ratios are weight ratios; product B includes: 15-18% specification 6-8 mesh white glass, 12-15% specification 10-20 mesh white glass, 1.3-1.5% specification 6-8 mesh gray background lens, 3-4% specification 16-30 mesh gray backgroun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com