Door handle structure of vehicle

A door handle and vehicle technology, applied in vehicle locks, vehicle parts, doors, etc., can solve problems such as damage to the visual and auditory texture, collision between door handle rods and switches, etc., to reduce the load and prevent misoperation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] An embodiment of the present invention will be described in detail based on the following drawings.

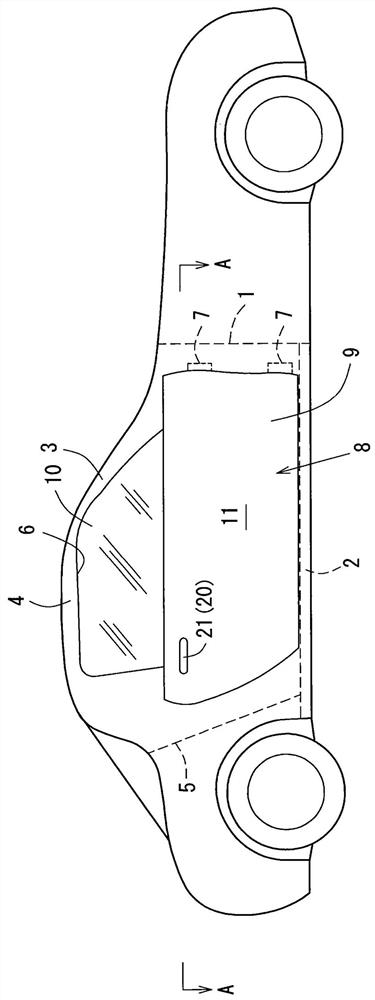

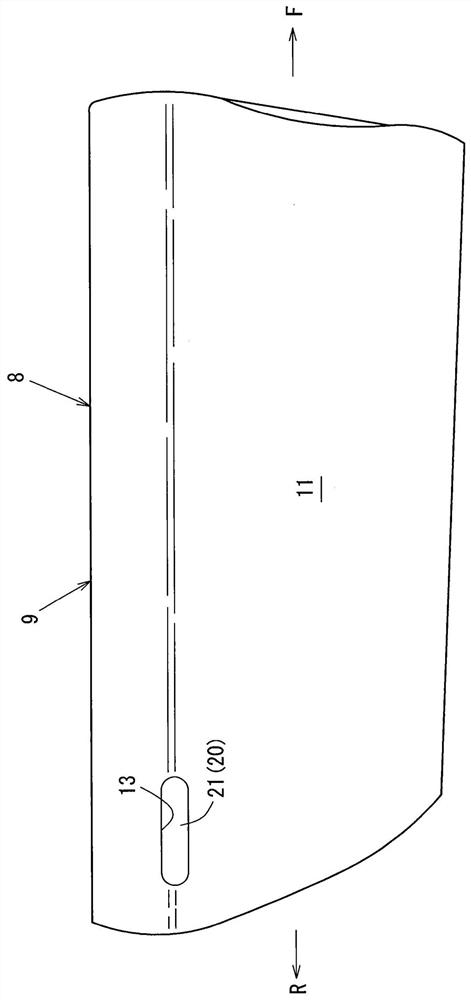

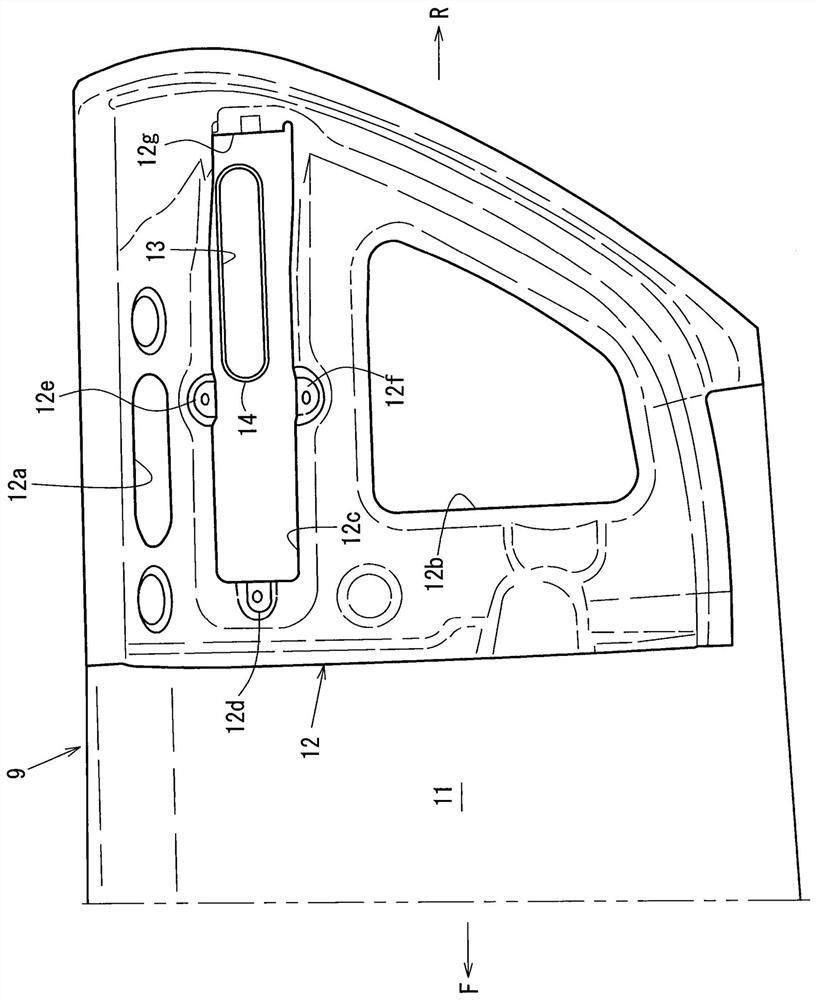

[0052] The accompanying drawing shows the structure of a door handle of a vehicle, figure 1 It is a side view of a vehicle equipped with the door handle structure, figure 2 for figure 1 The main part of the enlarged side view, image 3 An inner side view of the configuration structure for the reinforcement.

[0053] In addition, in the figure, the arrow F represents the front of the vehicle, the arrow R represents the rear of the vehicle, the arrow UP represents the upper side of the vehicle, and the arrow OUT represents the outside in the vehicle width direction.

[0054] In addition, the door handle structure of the vehicle of the present invention can also be applied to the front door, rear door, liftgate, etc. of a 4-door type vehicle.

[0055] like figure 1 As shown, a vehicle having the above door handle structure includes a hinge pillar 1 extending in the v...

Embodiment 2

[0124] Next, refer to Figure 13 to Figure 22 Embodiment 2 of the door handle structure of the vehicle will be described.

[0125] Figure 13 It is a sectional view of the storage state of the handle of Embodiment 2, Figure 14 is the top view of the drive unit, Figure 15 is the top view of the force applying structure involved in the force applying unit, Figure 16 is the top view of the protruding initial position of the handle, Figure 17 is a top view of the grip position of the handle, Figure 18 is a top view of the open position of the handle, Figure 19 Top view of the switch press position for the handle.

[0126] in addition, Figure 20 is the inner side view of the bracket, Figure 21 for the edge Figure 20 Sectional view of line B-B, Figure 22 It is an explanatory diagram of the movement trajectory of the handle, the hinge arm, and the sliding member.

[0127] Furthermore, in Figure 13 to Figure 22 In the drawings, the same symbols are used for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com