Skid-mounted profile control high-pressure injection pipe structure

A high-pressure injection, pipe structure technology, applied in the field of injection pipes, can solve the problems of complex, uneven and inconvenient transportation of petroleum additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

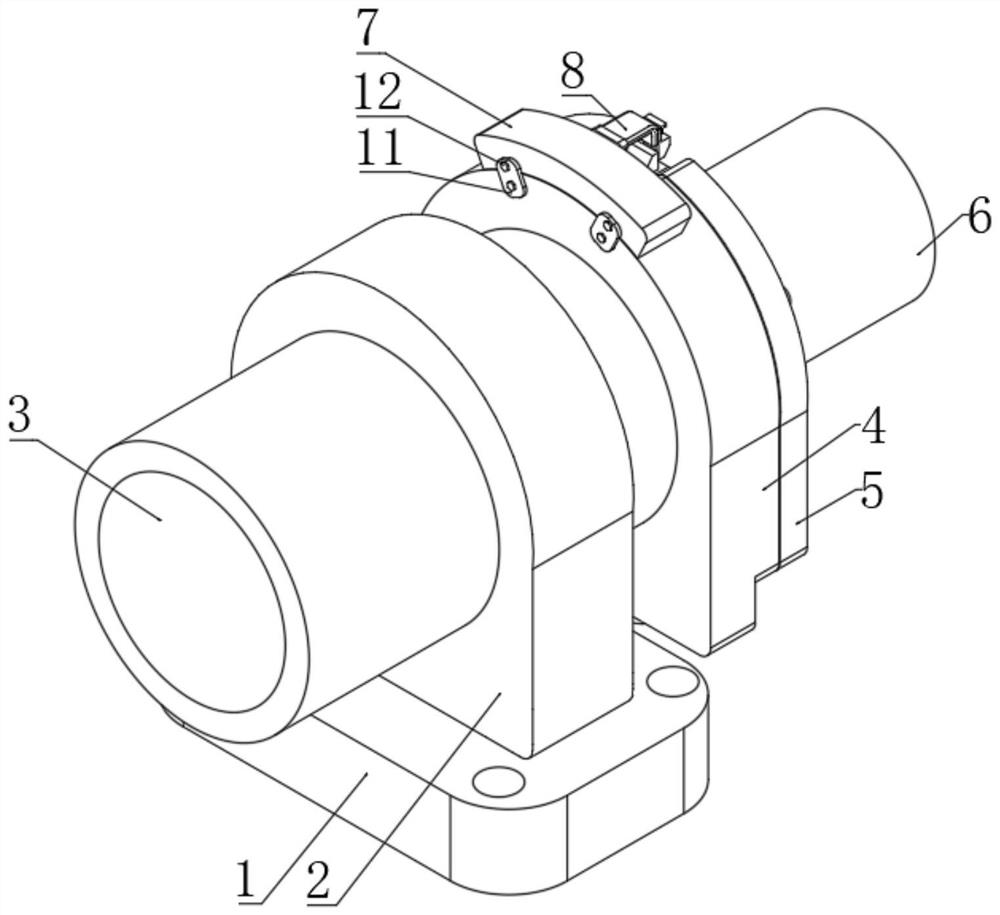

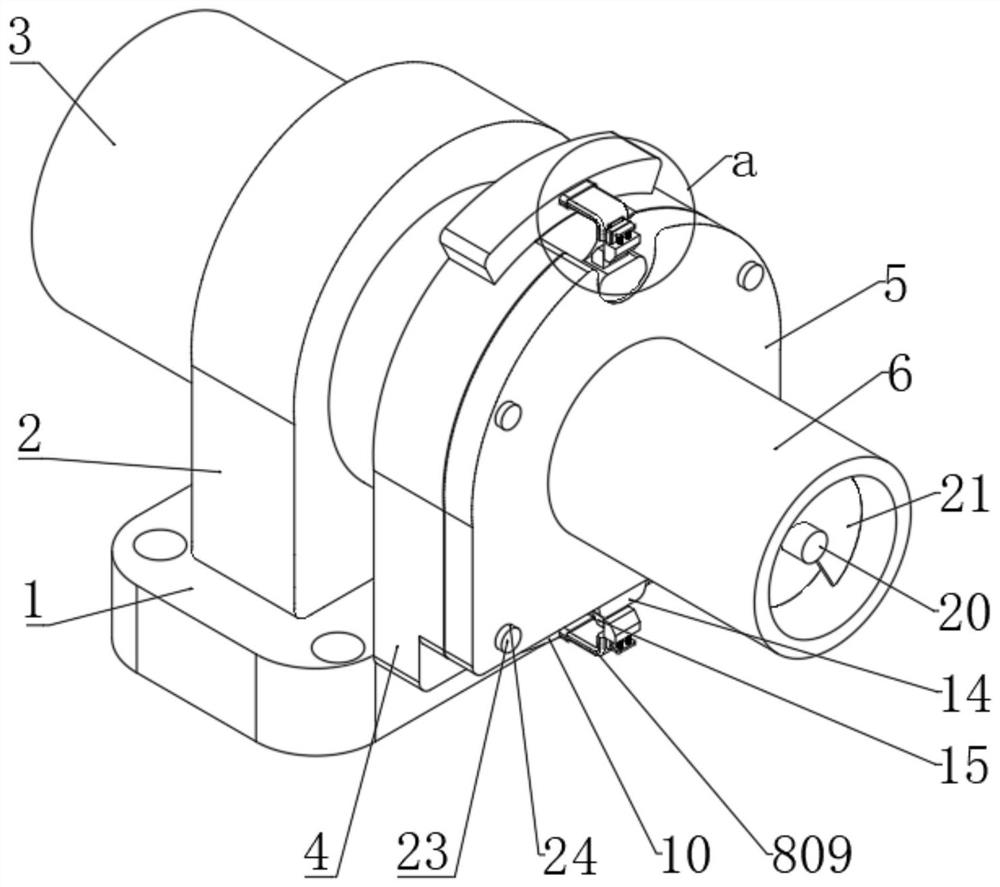

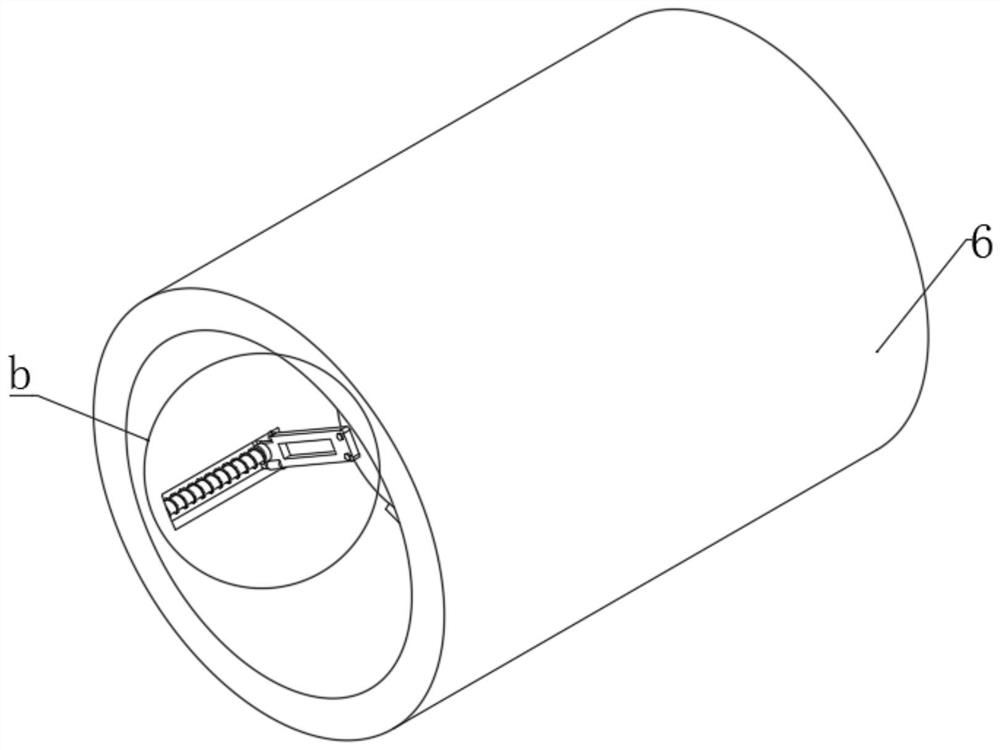

[0032] like Figure 1-8 As shown, a skid-mounted profile control high-pressure injection pipe structure includes a base 1, an installation ring 2 is fixedly installed on the upper surface of the base 1, a first pipe 3 is fixedly installed inside the installation ring 2, and one end of the first pipe 3 is fixedly installed. A first installation block 4 is fixedly installed, one end surface of the first installation block 4 is in close contact with the second installation block 5, one end of the second installation block 5 is fixedly connected with the second pipe 6, and the upper and lower ends of the first installation block 4 are respectively The top block 7 and the bottom block 10 are installed, and one end surface of the top block 7 and the bottom block 10 is provided with a clamping assembly 8. The clamping assembly 8 includes a second clamping block 801 and a first spring 802. One end surface is fixedly connected with the first spring 802 , one end of the two second block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com