Rotational flow and filtration integrated desander

A technology for cyclone filtration and desander, which is applied in the fields of production fluid, wellbore/well components, combustion engine, etc., can solve the problems of high installation accuracy, high manufacturing cost of desander, and reduced ventilation, etc. Extend the use and cleaning cycle, reduce installation and commissioning time, and reduce the effect of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

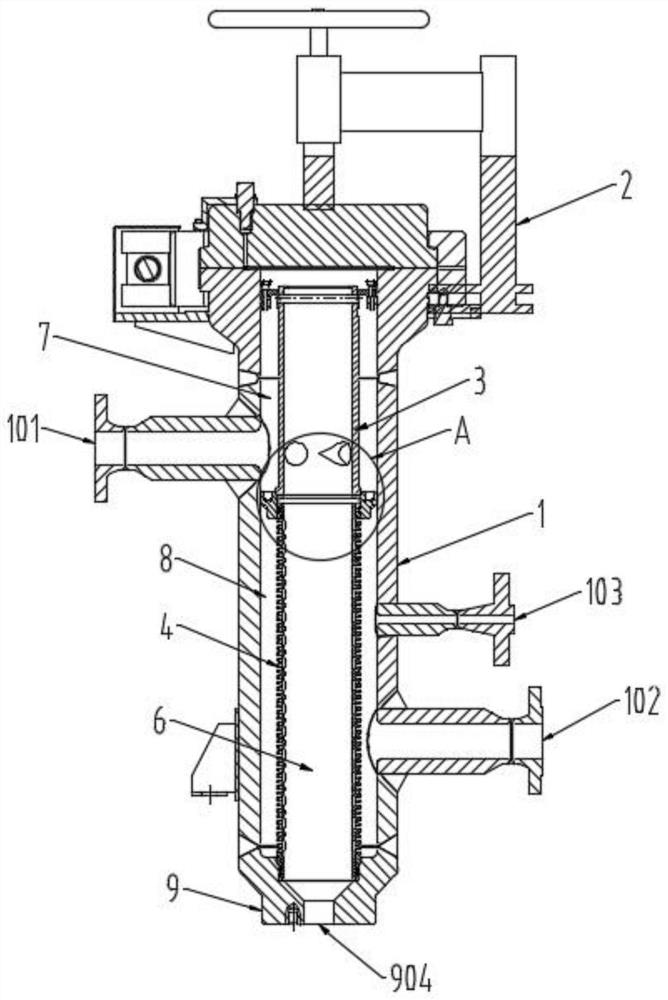

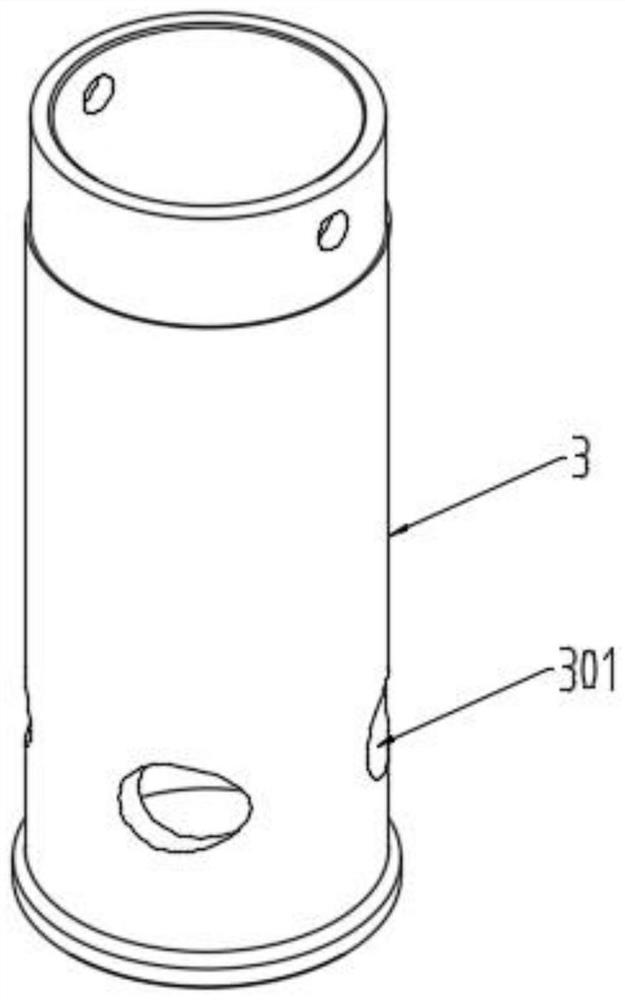

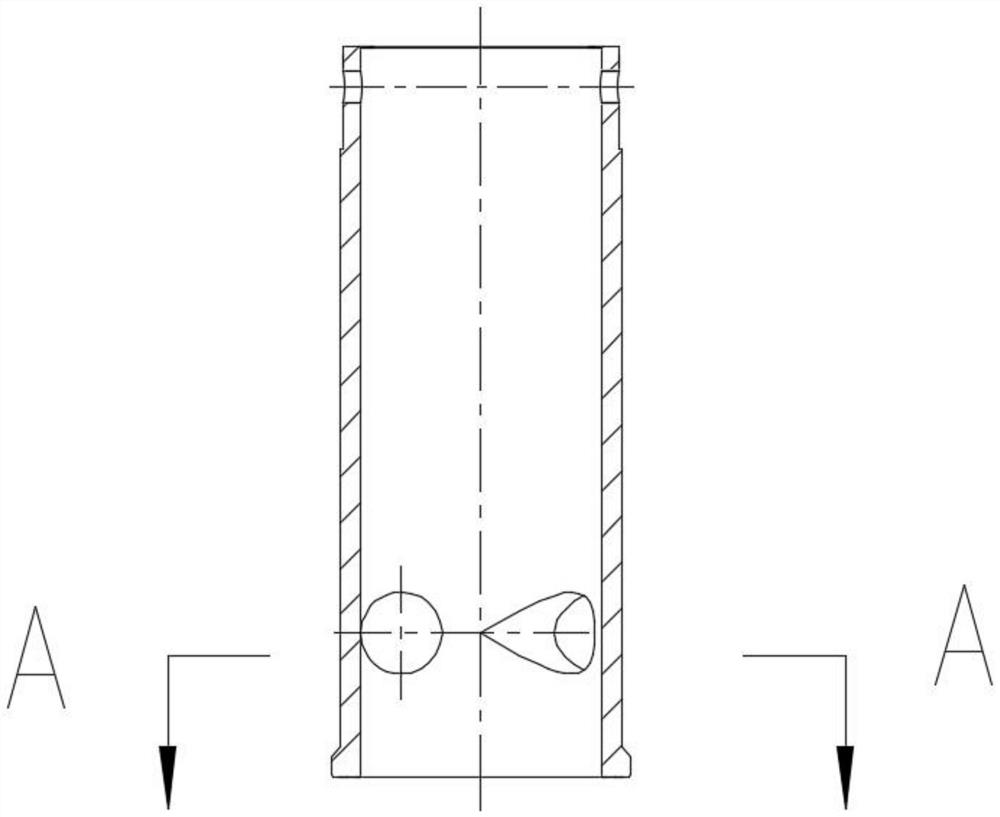

[0027] see figure 1 , this embodiment discloses a cyclone filter integrated desander, including a sleeve 1, the top of the sleeve 1 is installed with a quick-opening blind plate 2, the lower end of the sleeve 1 is installed with a lower head 9, the sleeve The cylinder 1 is provided with an air inlet 101 , an air outlet 102 and a recoil port 103 . The sleeve 1 is provided with a swirl sleeve 3 and a filter element 4 that are connected end to end, and the swirl sleeve 3 is provided with a swirl structure that makes the incoming gas swirl downward; the outer wall of the swirl sleeve 3 is connected to the There is an annular air inlet cavity 7 between the sleeve 1, an annular air outlet cavity 8 between the filter element 4 and the inner wall of the sleeve 1, the annular air inlet cavity 7 and the annular air outlet cavity 8 are sealed, and the air inlet 101 It communicates with the annular air inlet cavity 7 , the air outlet 102 and the recoil opening 103 communicate with the an...

Embodiment 2

[0036] This embodiment discloses a cyclone filter integrated desander, which is different from Embodiment 1 in that, see Figure 6-7 , the sealing mechanism of this embodiment is an axial seal, which includes a sealing ring 51 and a conversion sleeve 52, the conversion sleeve 52 is connected between the filter element 4 and the swirl sleeve 3, and the sealing ring 51 is connected to the Between the conversion sleeve 52 and the inner wall of the sleeve 1 . In addition, in order to reduce stress concentration caused by deformation under high pressure, prevent weld cracking and affect equipment function, stress relief grooves (not shown in the figure) may also be provided on the sealing ring 51 in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com