Transmission, gear shifting fork structure and assembling method of gear shifting fork structure

A shift fork and assembly method technology, applied in the direction of instruments, controlled components, mechanical control devices, etc., can solve the problems of heavy weight, increased cost, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make those skilled in the art better understand the solution of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0038] For ease of understanding and concise description, the following description will be combined with the transmission and its shift fork structure, and the beneficial effects will not be repeated.

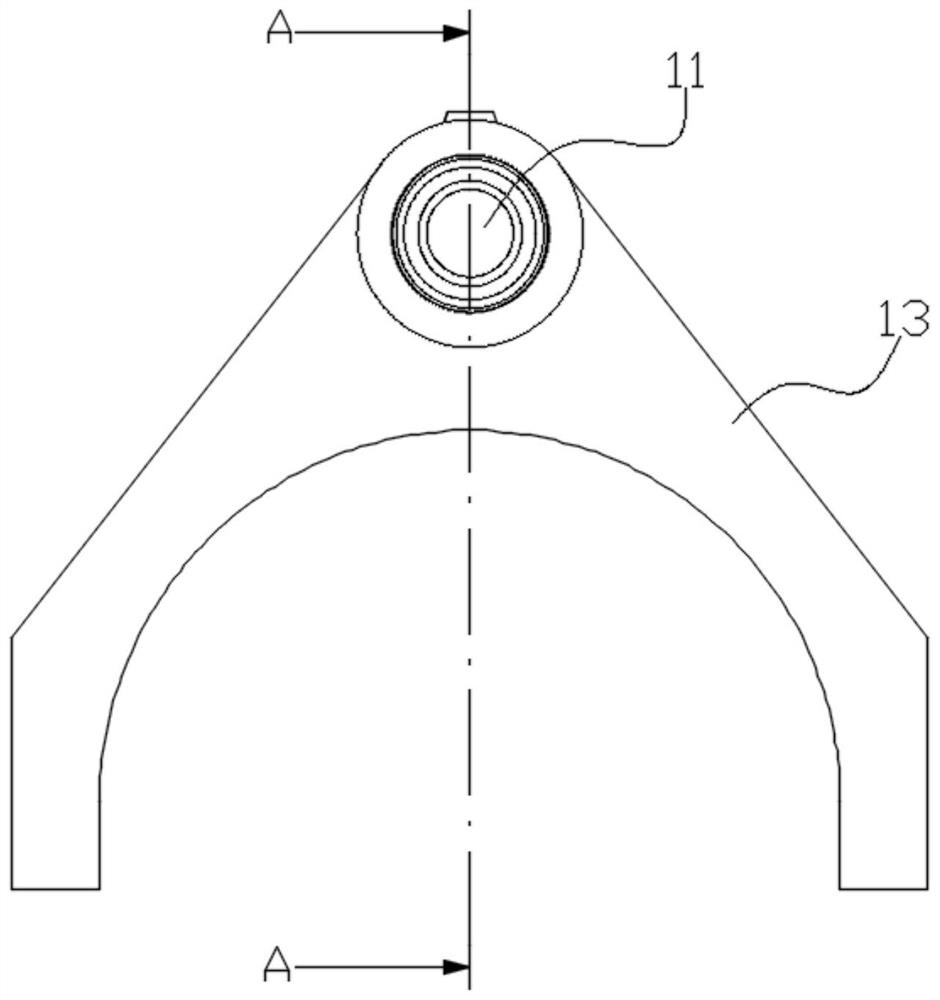

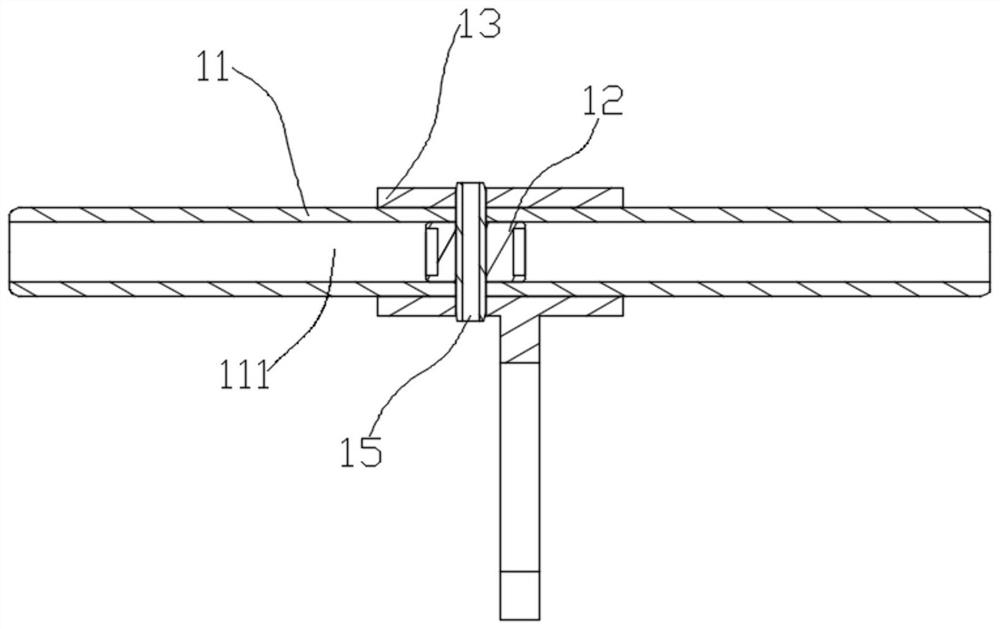

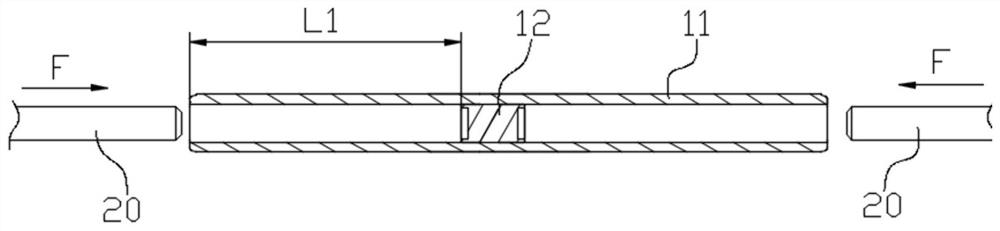

[0039] In this embodiment, the transmission includes a synchronizer sleeve, a shift gear and a shift fork structure, and the shift fork structure is used to push the synchronizer sleeve to engage or disengage from the shift gear, thereby realizing the transmission gear. bit change. Among them, the relative positional relationship and action principle of the synchronizer sleeve, the shift gear and the shift fork structure can be referred to the prior art. This paper focuses on improving the shift fork structure. The following focuses on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com