A kind of high-strength and high-toughness die-casting aluminum alloy and products thereof

A technology of casting aluminum alloy and high toughness, applied in the field of aluminum alloy casting, can solve problems such as being unable to meet high strength, high toughness, impact resistance, unable to meet the development needs of high-stress parts of automobiles, and not belonging to high strength and high toughness. , to achieve good application prospects, good casting process performance, and good fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

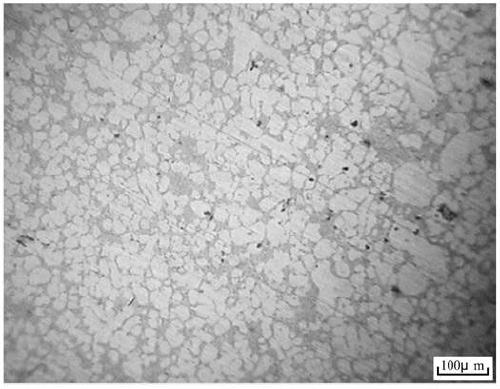

Image

Examples

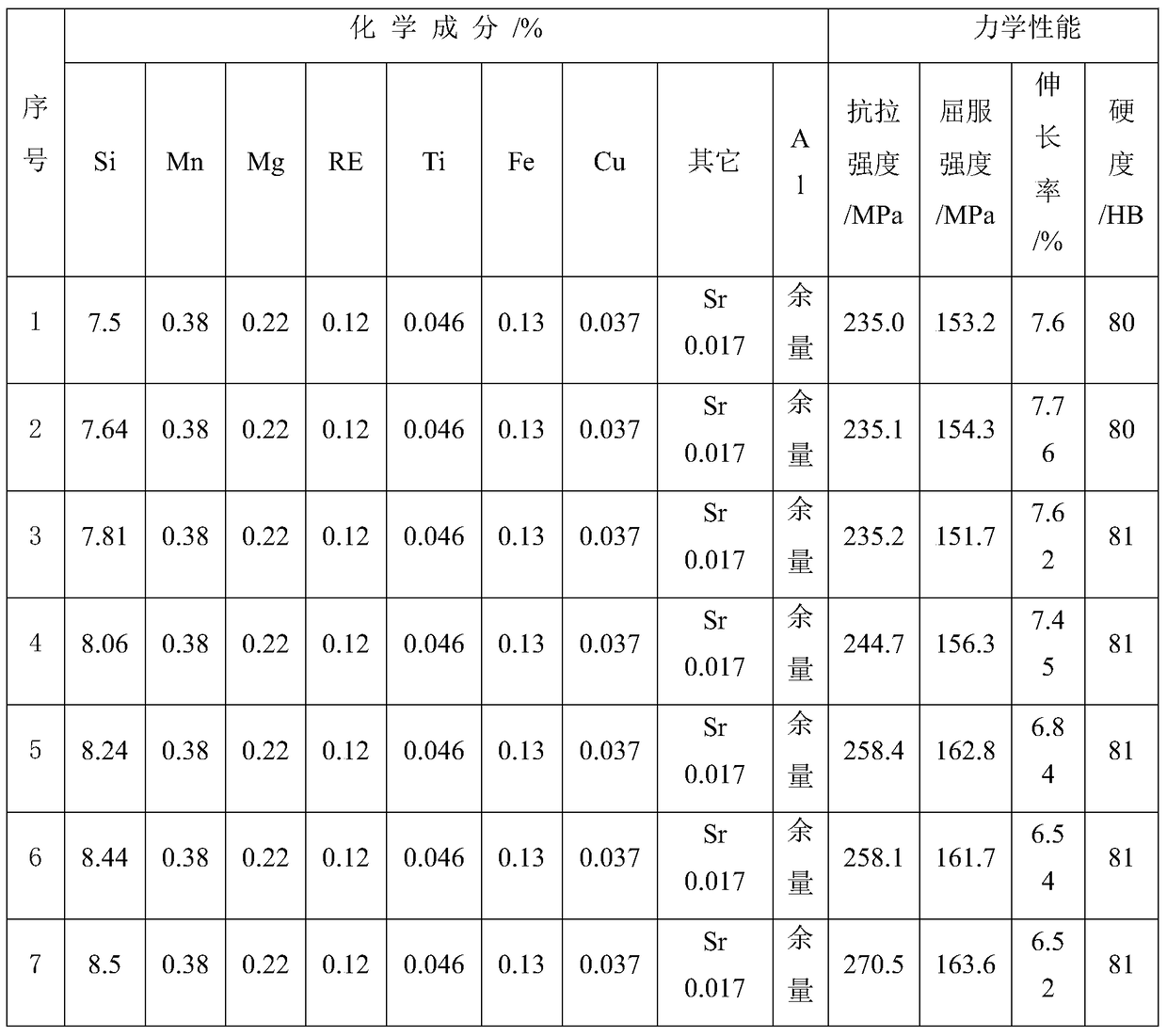

Embodiment 1

[0020] Prepare high-strength and high-toughness die-casting aluminum alloys with different silicon contents, and use the alloys prepared above with different silicon contents to perform die-casting according to the high vacuum die-casting process of the present invention. The main die-casting process parameters used are: the vacuum degree of the mold cavity is 93 ± 2KPa , the die-casting pressure is 80±5MPa, the pouring temperature of molten aluminum is 710±10℃, the injection speed is 4.5±0.5m / s, the mold temperature is 180±10℃, the samples with a wall thickness of 4mm are prepared, and the samples with different silicon contents are measured. The mechanical properties of the sample are shown in Table 1.

[0021] Table 1 Material composition and mechanical properties of high-strength and high-toughness die-casting aluminum alloys with different silicon contents

[0022]

[0023] It can be seen from Table 1 that with the increase of Si content, the tensile strength and yield...

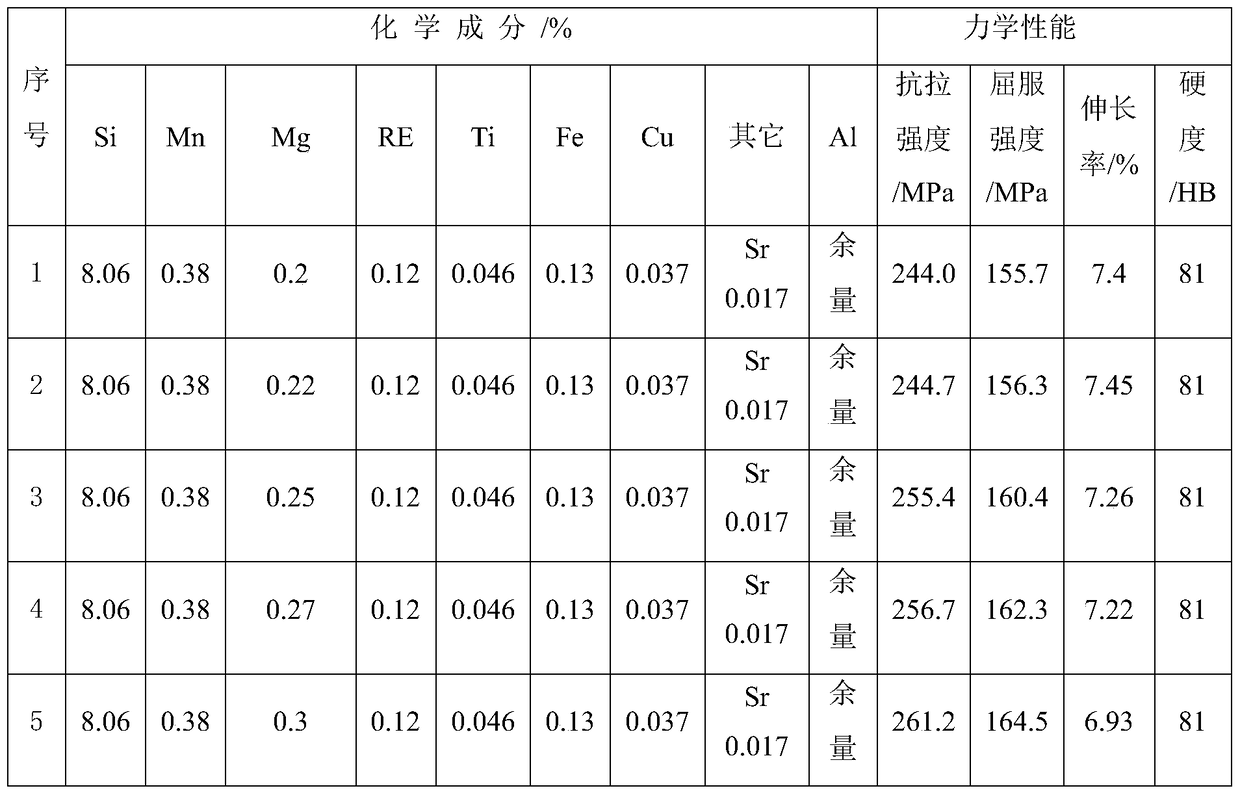

example 2

[0026] Prepare high-strength and high-toughness die-casting aluminum alloys with different magnesium contents, and use the above-mentioned prepared alloys with different magnesium contents to carry out die-casting according to the vacuum die-casting process. The main die-casting process parameters used are: mold cavity vacuum degree 93±2KPa, die-casting pressure 80± 5MPa, aluminum liquid pouring temperature 710±10°C, injection speed 4.5±0.5m / s, mold temperature 180±10°C, prepare a flat sample with a wall thickness of 4mm, and measure the mechanical properties of samples with different magnesium contents ,As shown in table 2.

[0027] Table 2 Material composition and mechanical properties of high-strength and high-toughness die-casting aluminum alloys with different magnesium contents

[0028]

[0029] It can be seen from Table 2 that with the increase of Mg content, the tensile strength and yield strength of the sample gradually increased, while the elongation decreased. T...

example 3

[0031] Prepare high-strength and high-toughness die-casting aluminum alloys with different compositions, and use the alloys prepared above to carry out die-casting according to the vacuum die-casting process. The main die-casting process parameters used are: mold cavity vacuum degree 93±2KPa, die-casting pressure 80±5MPa , the pouring temperature of molten aluminum is 710±10°C, the injection speed is 4.5±0.5m / s, the mold temperature is 180±10°C, and a flat sample with a wall thickness of 4mm is prepared, and the mechanical properties of samples with different components are measured, such as Table 3 shows.

[0032] Table 3 Mechanical properties of materials with different compositions

[0033]

[0034] As can be seen from Table 3, the tensile strength, yield strength, elongation and hardness of the sample prepared by the alloy of the present invention all meet the requirements of tensile strength ≥ 230MPa, yield strength ≥ 150MPa, elongation ≥ 6%, hardness ≥ 80HB is requir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com